Environment-friendly nodular cast iron pipe inner wall grinding and cleaning equipment

A technology for ductile iron pipes and cleaning equipment, which is applied to grinding/polishing equipment, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces. It can solve problems such as difficult cleaning, extra flushing, and poor environmental protection, and achieve improved Effects of cleaning, improving utilization, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

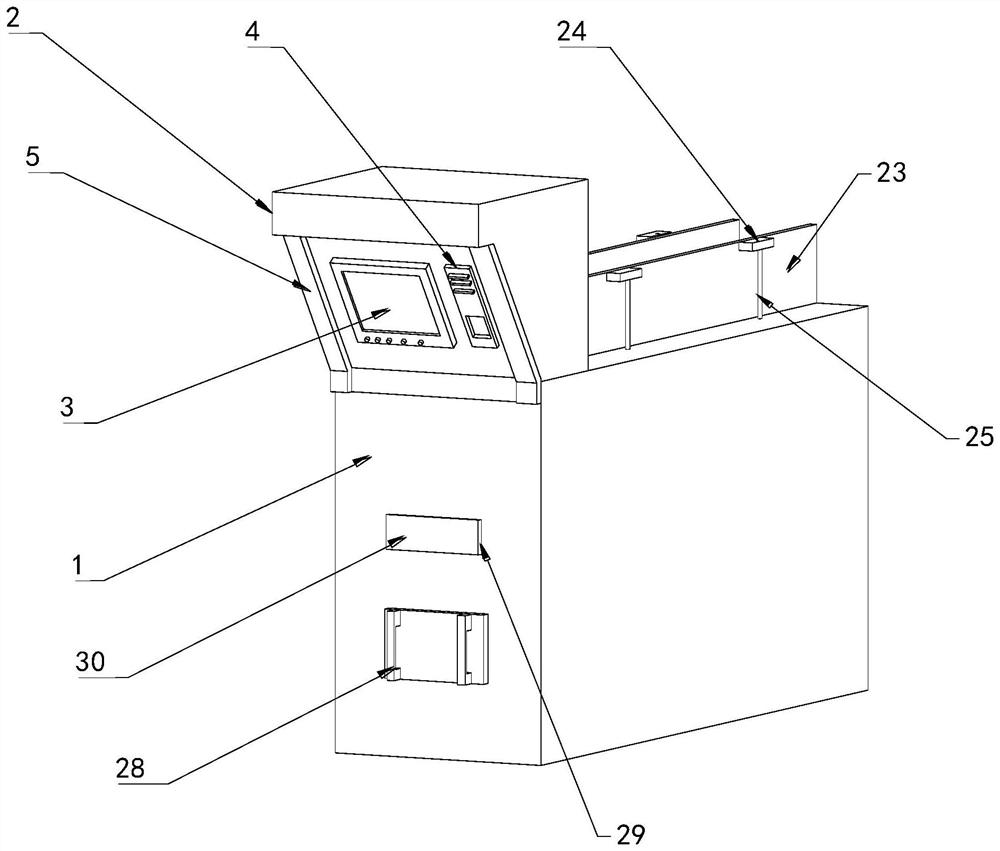

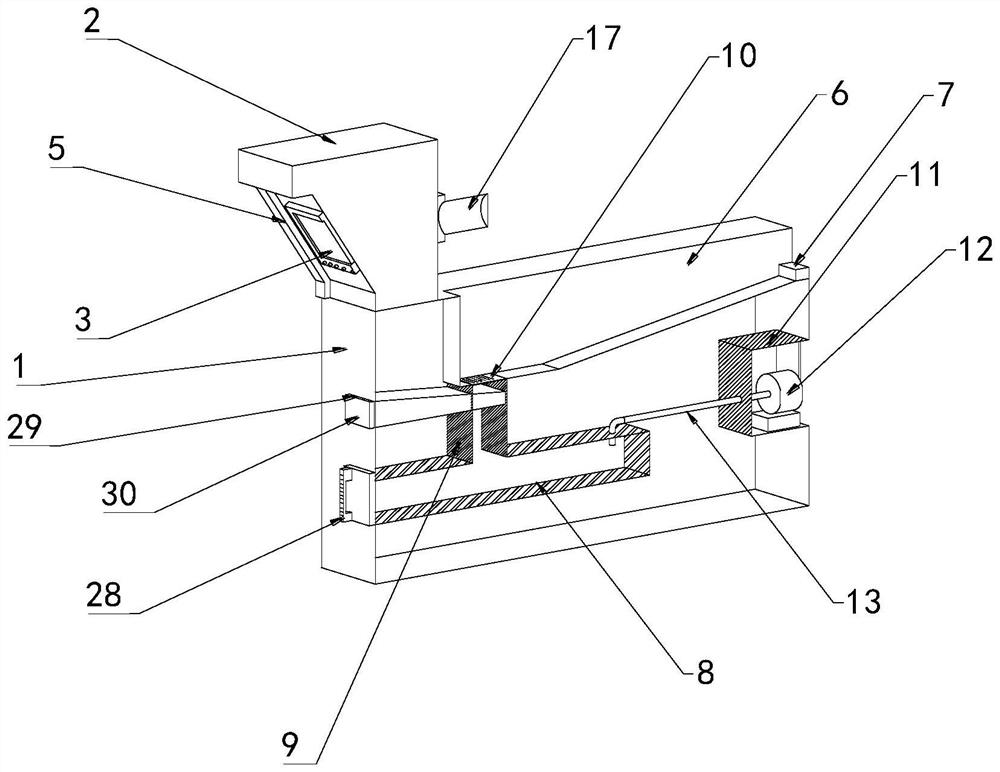

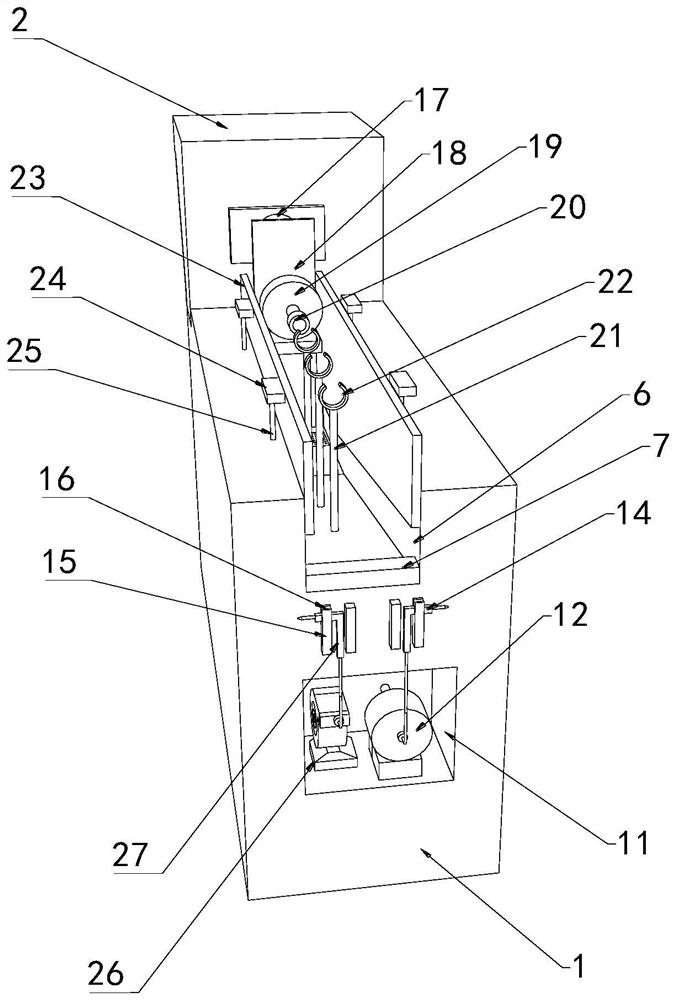

[0034] Embodiment: a kind of environment-friendly type nodular cast iron pipe inner wall grinding and cleaning equipment, such as Figure 1-Figure 5 As shown, it includes a processing table 1 and a console 2. The front side wall of the console 2 is equipped with a control display screen 3 and a controller 4. The top of the processing table 1 is provided with an inverted trapezoidal processing tank 6. The inner bottom surface of the processing tank 6 is The rear end is fixedly connected with a stopper 7, and the inside of the processing tank 6 is provided with a cleaning water recovery system. The cleaning water recovery system includes a water tank 8 installed inside the processing table 1, and the top of the water tank 8 is provided with a recovery pipe connected to the bottom surface of the processing tank 6. 9. The top opening of the recovery pipe 9 is provided with a filter screen 10, and the rear side of the processing table 1 is provided with a treatment tank 11. The insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com