Annular water-cooling protection plate and manufacturing method thereof

A ring-shaped water-cooling and production method technology, which is applied to cooling devices, blast furnace parts, furnaces, etc., can solve the problems of "serpentine" water-cooled protection plates with large welding volume, high operating process requirements, and many welding nodes, etc., and achieve simple structure , wide applicability and small welding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

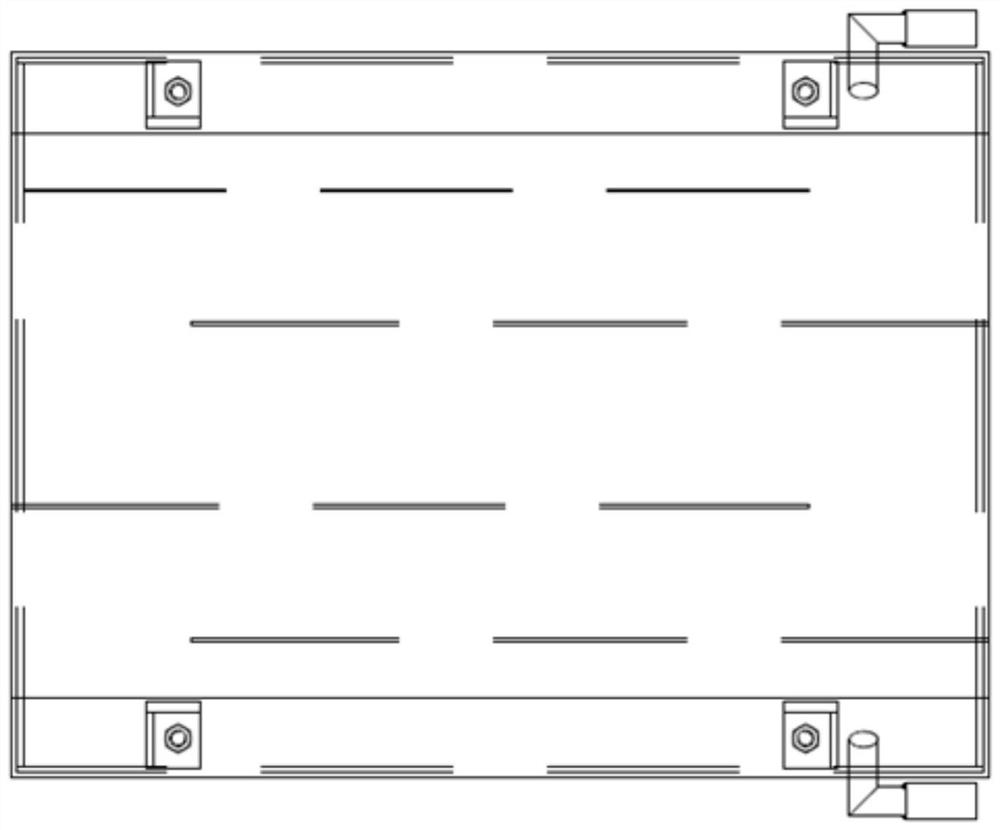

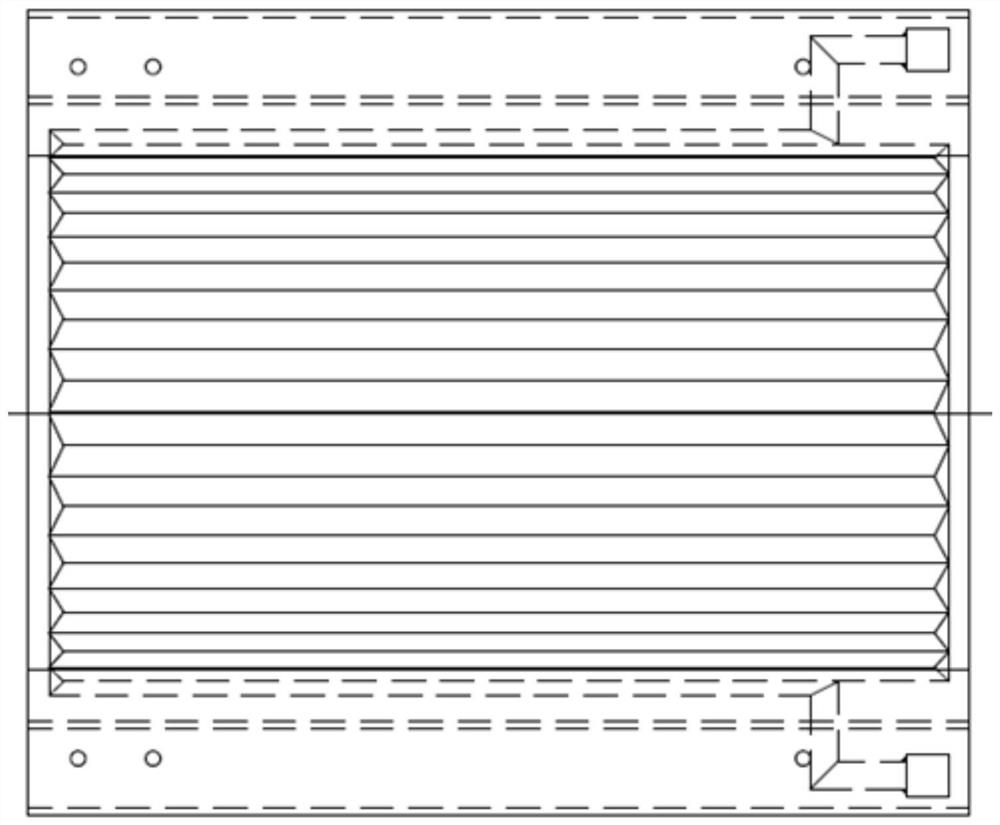

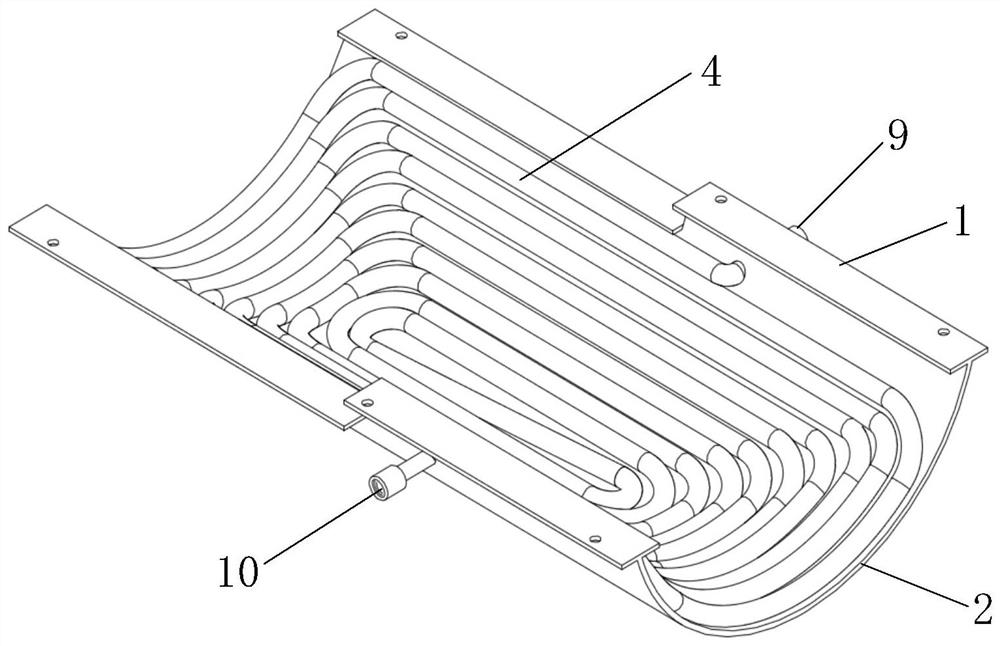

[0044] see Figure 3-5 As shown, the present invention provides a ring-shaped water-cooled protective plate, including a steel plate 1 and an arc-shaped guard plate 2, the steel plate 1 and the arc-shaped guard plate 2 are welded and fixed, and the inner arc surface of the arc-shaped guard plate 2 is installed with Water-cooled pipe structure; the water-cooled pipe structure adopts a spiral pipe layout method, which includes a central pipe assembly. The central pipe assembly is composed of two elbows and a central pipe 5. The A end of the first elbow 3 is connected to the center One end of the pipe 5 is welded, and the other end of the central pipe 5 is welded to the C end of the second elbow 6; the B end of the first elbow 3 is connected to the water inlet pipeline 7, and the second elbow 6 The D end of D is in communication with the return water pipeline 8, and the water inlet pipeline 7 and the water return pipeline 8 are arranged alternately.

[0045] Further, the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com