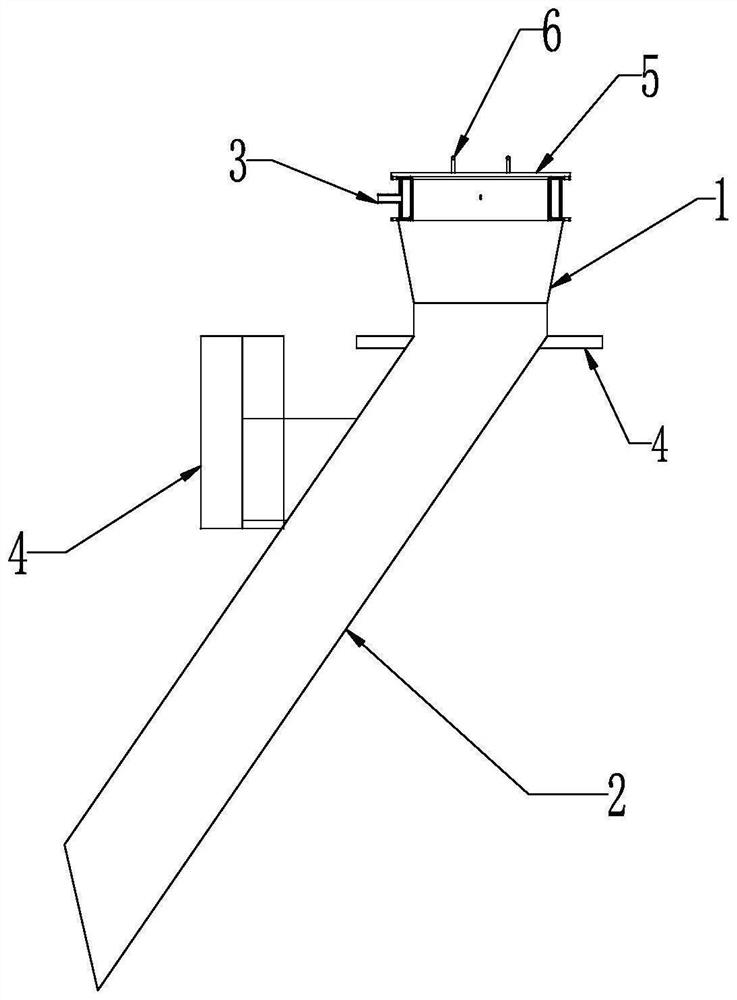

Method for preventing low-temperature high-sulfur vanadium-titanium molten iron KR desulfurization bag overflowing

A ladle and high-sulfur technology is applied in the field of preventing the flooding of KR desulfurization in low-temperature high-sulfur vanadium-titanium molten iron, which can solve the problems of loss of molten iron, damage to desulfurization equipment, and large splash of molten iron, so as to ensure smooth production and reduce the loss of molten iron. , the effect of suppressing the diffuse packet phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: 1500kg of desulfurizer (CaO≥75%) is directly added into the molten iron ladle

Embodiment 2

[0038] Example 2: Add 1500kg of desulfurizer (CaO≥75%) and 180kg of 45 silicon carbide particles (particle content of 1-5mm diameter ≥90%) into the molten iron ladle at the same time

Embodiment 3

[0039] Example 3: Add 1500kg of desulfurizer (CaO≥75%) and 150kg of 65 silicon carbide particles (particle content of 1-5mm diameter ≥90%) into the molten iron ladle at the same time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com