Laser cladding boride-based wear-resistant coating as well as preparation method and application thereof

A technology of laser cladding and wear-resistant coating, which is applied in coating, metal material coating process, etc., can solve the problems of difficult production and high brittleness, and achieve the effect of fast heat dissipation, low production cost and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

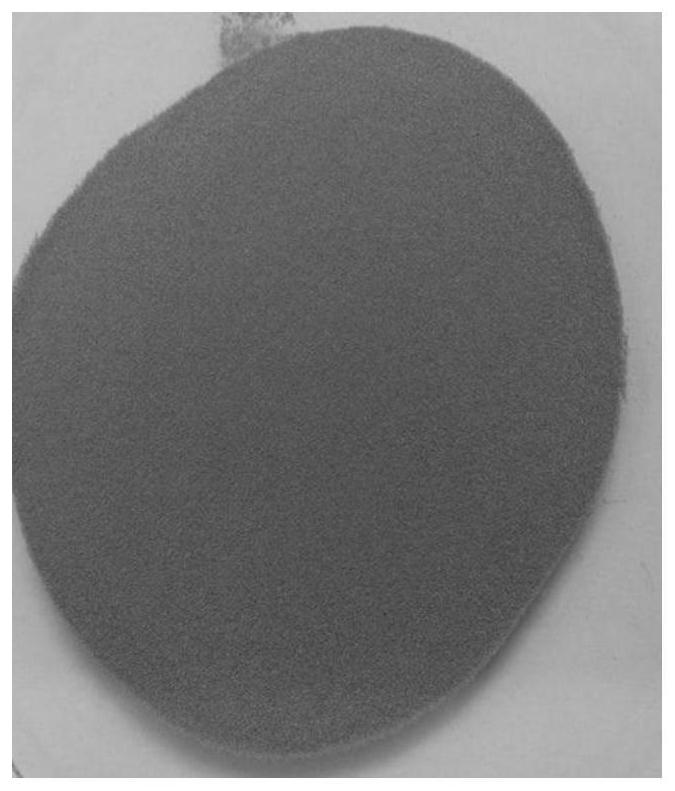

[0031] A laser cladding boride-based wear-resistant coating comprises the following raw materials in mass percentage: 48wt% of Mo powder, 24wt% of Fe powder, and 28wt% of FeB powder.

[0032] The above-mentioned laser cladding boride-based wear-resistant coating is prepared according to the following steps:

[0033] Weigh raw materials according to the following mass percentages: Mo powder 48wt%, Fe powder 24wt%, FeB powder 28wt%, standby;

[0034] Under the protection of an inert gas, put the raw materials in a planetary ball mill for ball milling, select SiC balls, use the wet milling method for ball milling, and pass in argon as a protective gas to prevent powder oxidation. The specific ball milling parameters are: The ball material ratio is 6:1; the total mass ratio of ethanol to powder is 1:1; the ball milling speed is 260r / min, and the ball milling time is 16 hours; the powder scale distribution after ball milling is uniform, and the size meets the laser cladding powder ...

Embodiment 2

[0041] Same as Example 1, except that the following mass percentages of raw materials are included: Mo powder 50wt%, Fe powder 20wt%, FeB powder 30wt%; the particle size of the coating powder is about 15 μm.

Embodiment 3

[0043]Same as Example 1, except that the following mass percentages of raw materials are included: Mo powder 50wt%, Fe powder 25wt%, FeB powder 25wt%; the particle size of the coating powder is about 45 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com