Electronic-grade glass fiber wear resistance testing device and testing method

A glass fiber and testing device technology, applied in the direction of measuring devices, testing wear resistance, strength characteristics, etc., can solve the problems of not being able to observe the shape change of the yarn, and not being able to improve the yarn in a targeted manner, so as to reduce the error of the test environment, Precise tension control and large winding diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

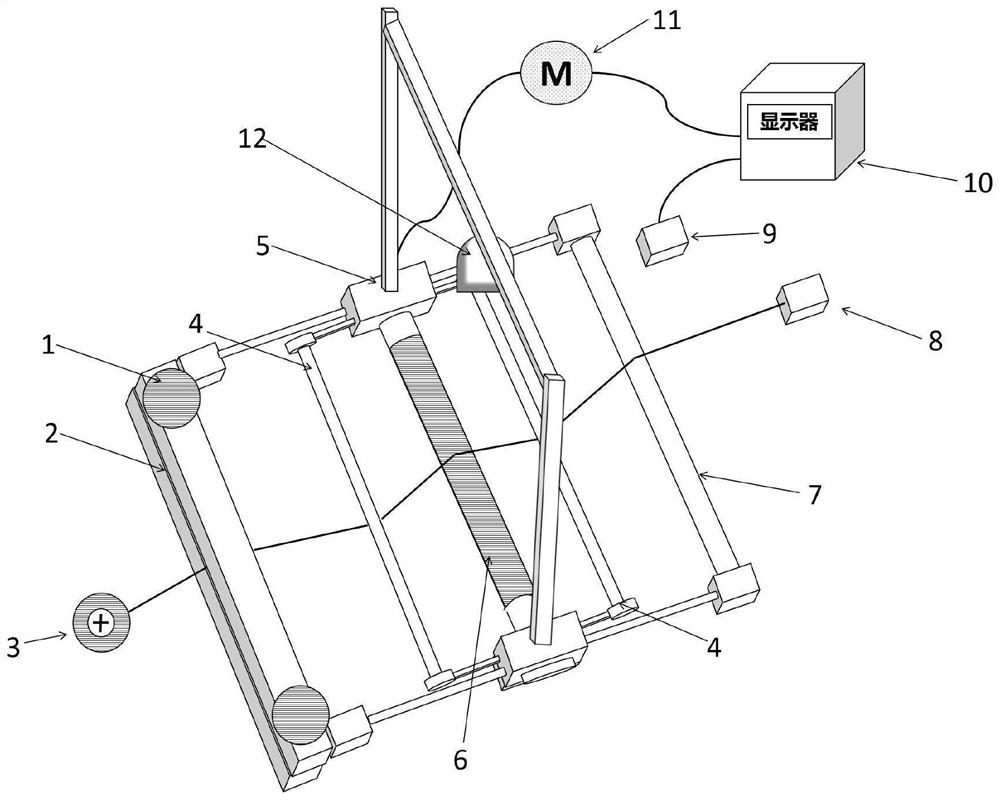

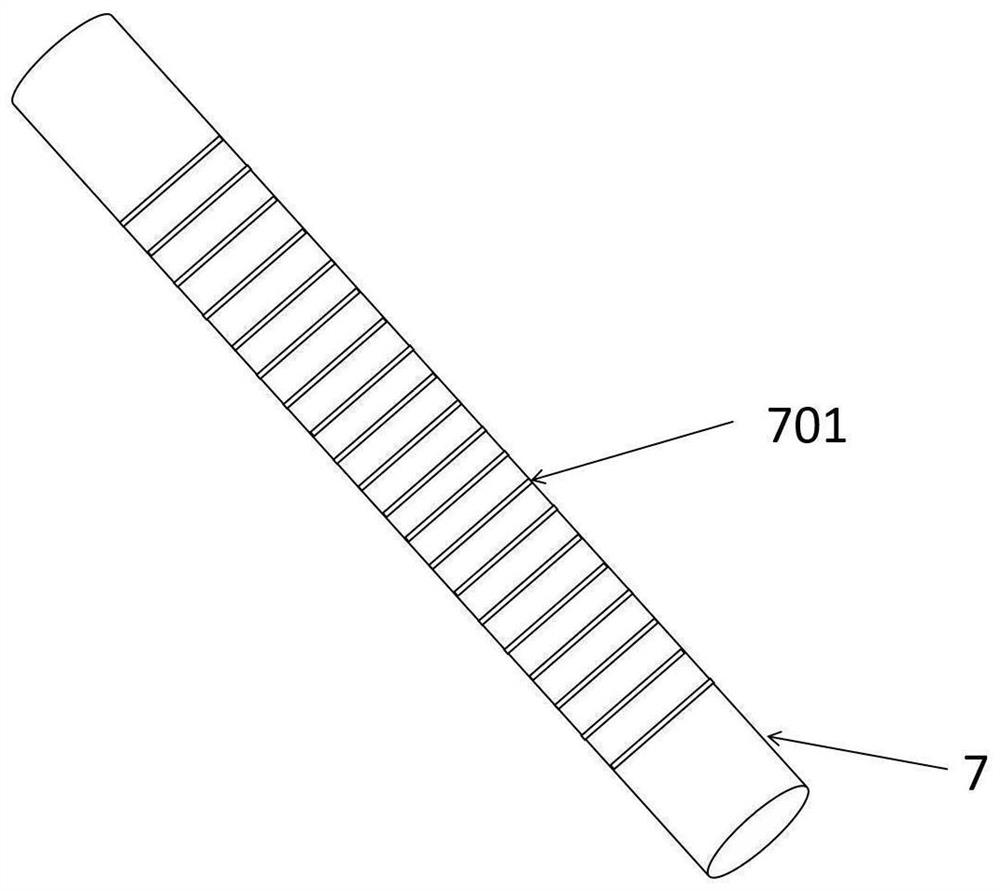

[0049] Such as Figure 1-6 As shown, a kind of electronic grade glass fiber abrasion resistance testing device described in the present invention comprises glass fiber yarn, yarn fixing device 3, grinding roller 6 and yarn guide rod 4, and glass fiber yarn passes through fixing device 3 , yarn guide rod 4, yarn grinding rod 6, limit yarn guide rod 7 are connected with tension control device 8, the outside of grinding yarn roller 6 is connected with motor 11, and the top of grinding yarn roller 6 is provided with high-speed camera 12, grinding yarn The left and right sides of the roller 6 are provided with a connecting rod 5, the connecting rod 5 is connected with the yarn guide rod 4 and the high-speed camera 12, the motor 11 is connected with a controller 10, the controller 10 is connected with an infrared sensor 9 and a counter, and the motor 11 drives The grinding roller 6 reciprocates, and at the same time, the high-speed camera 12 above the grinding roller 6 reciprocates ...

Embodiment 2

[0065] A method for testing the abrasion resistance of electronic grade glass fibers of the present invention comprises the following steps:

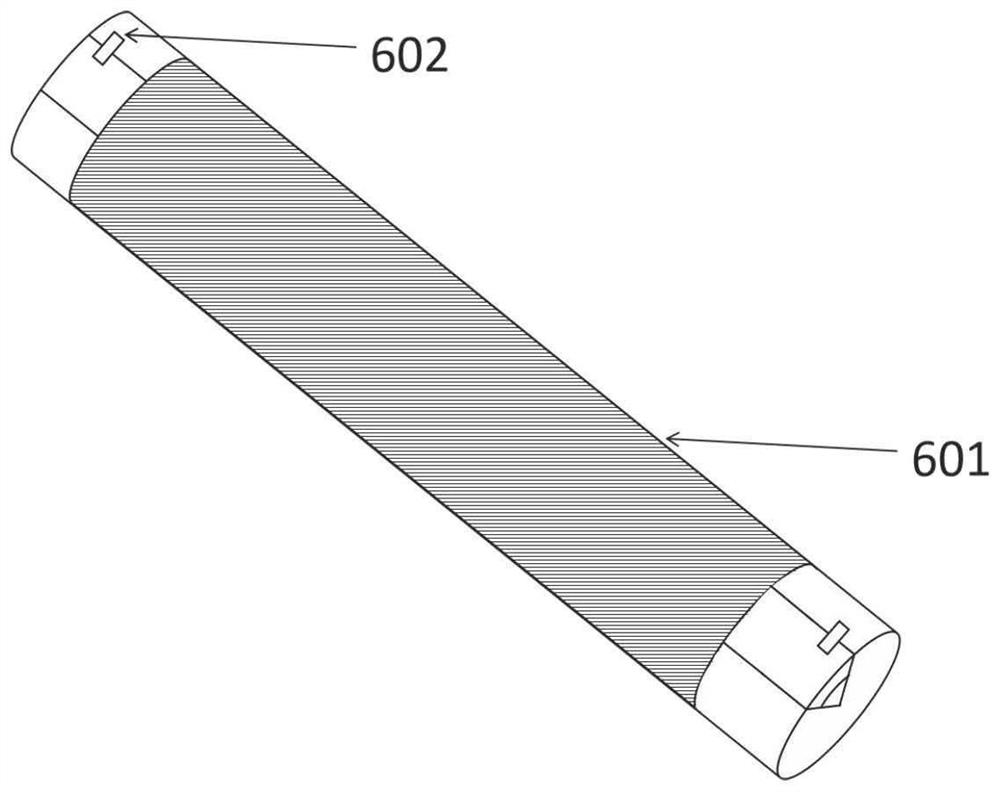

[0066] Step 1: Load and unload the grinding roller, turn the screw to remove the grinding roller cylinder, place the opening of the grinding roller cylinder on the top, then open the fixing buckles at both ends, fix the abrasive on the grinding roller cylinder, close the cylinder cylinder, the grinding roller cylinder is fixed on the connecting rod 5;

[0067] Step 2: Prepare the sample, sample the yarn, pass the sampled yarn through the limit yarn guide rod, yarn guide rod, grinding roller, and limit groove, and fix one end of the yarn in the working position When the yarn is fixed, the screw of the yarn fixing device is loosened first, the yarn is wound on the cylinder, and the screw is tightened to make the gasket press and fix the yarn. Connect the other end of the yarn to the tension control device, then cut the yarn, and apply te...

example 1

[0085] Example 1: The grinding roller uses 7628 glass fiber cloth (produced in-house). After the grinding roller reciprocates 2463 times, sample 1 breaks, the tension suddenly becomes 0, it takes 41 minutes, and the average number of hairiness is 28 when it breaks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com