Liquid circulation cooling method for nuclear power stations

A technology of liquid circulation and cooling method, which is applied in the directions of auxiliary equipment of nuclear power plants, nuclear power generation, and reduction of greenhouse gases, etc., can solve the problems of pollution, adverse effects of long-term cooling performance of scale, shortening of life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

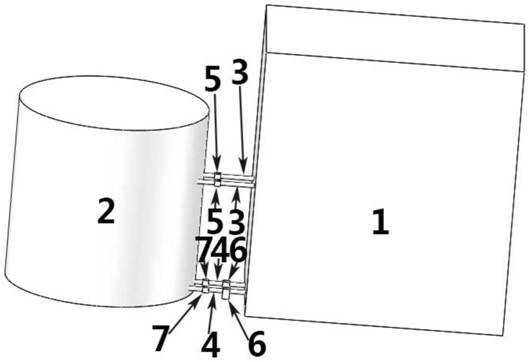

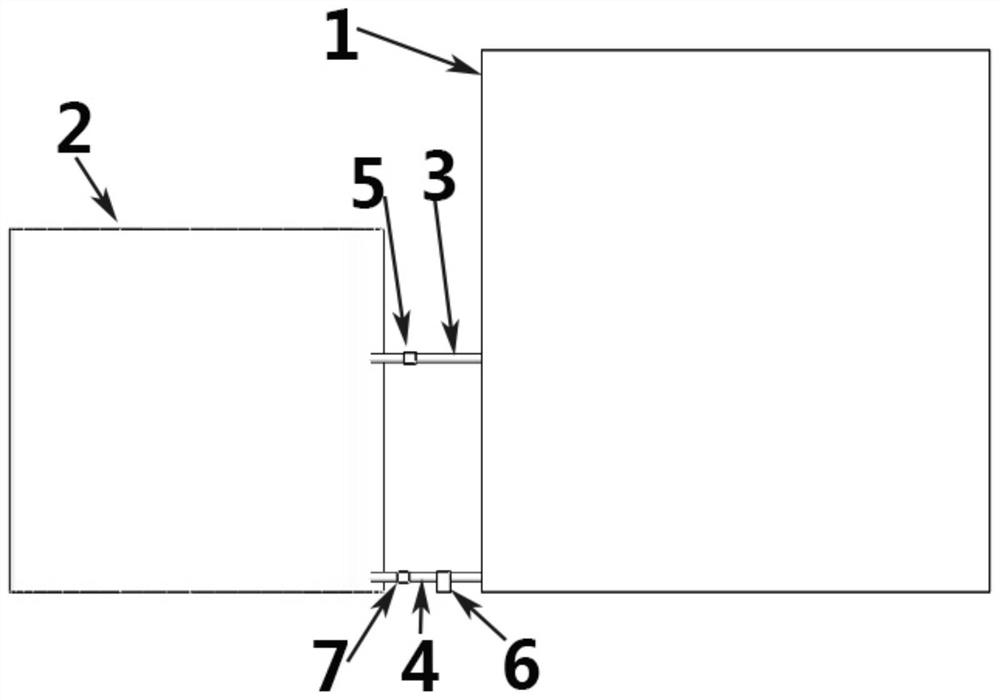

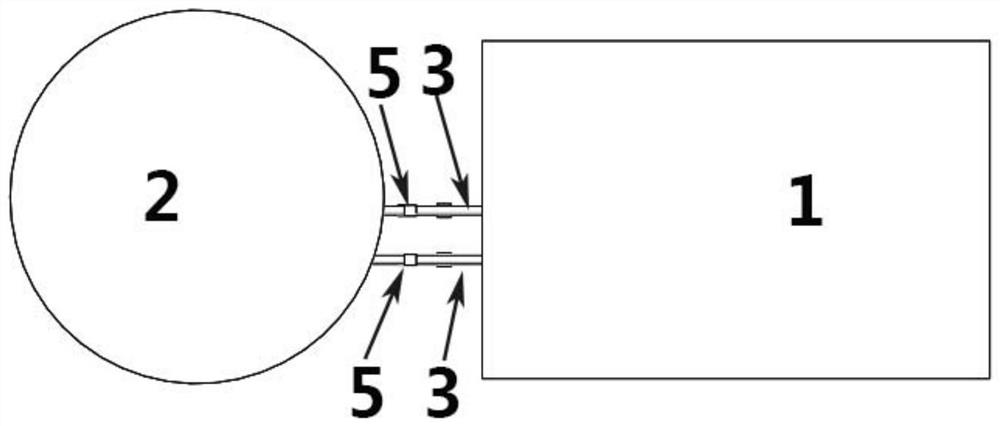

[0015] Such as figure 1 , figure 2 , image 3 The schematic diagram shown, the present invention is realized like this: a kind of nuclear power plant liquid circulation cooling method, by nuclear power plant 1, the cooling zone top inside nuclear power plant 1 is connected with liquid radiator 2 by nuclear power plant liquid discharge pipe 3, the cooling zone inside nuclear power plant 1 The lower part is connected to the liquid radiator 2 through the liquid input pipe 4 of the nuclear power plant to form a liquid circulation cooling closed-loop structure of the nuclear power plant 1. The liquid input pipe 3 of the nuclear power plant is connected in series with the liquid input driving device 6 of the nuclear power plant, the sensor group 7 of the liquid input pipe of the nuclear power plant, and the liquid discharge pipe 3 of the nuclear power plant The sensor group 5 of the nuclear power plant liquid discharge pipeline is connected in series, and the nuclear power plant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com