Automatic assembling device and method for supporting plate nut

A technology of pallet nuts and assembly devices, which is applied in the field of assembly technology, can solve the problems of low efficiency, poor quality consistency of manual assembly of pallet nuts, lack of assembly green manufacturing mode, etc., to reduce noise, facilitate rapid development, and improve assembly quality Effects with Mass Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

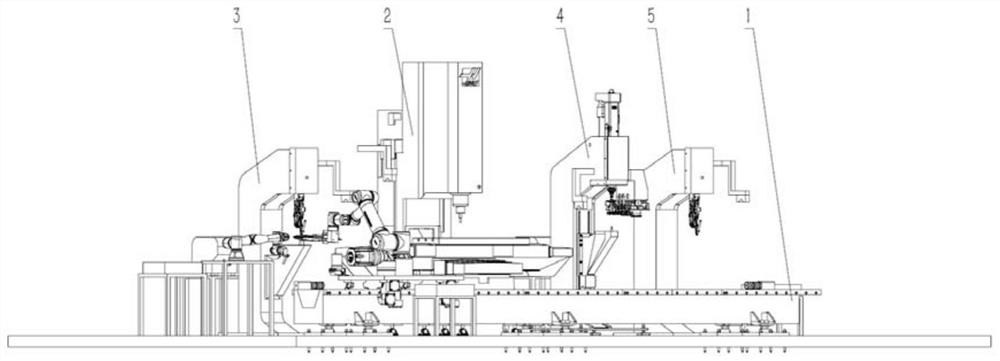

[0041] Attached below Figure 1-8 The present invention will be described in further detail with reference to specific embodiments.

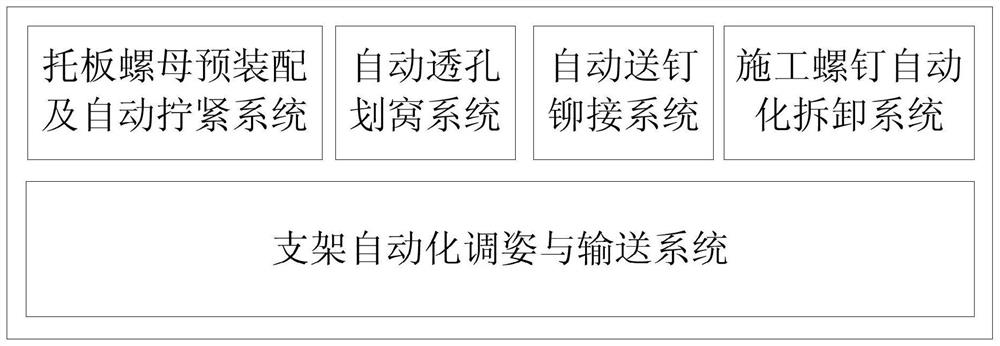

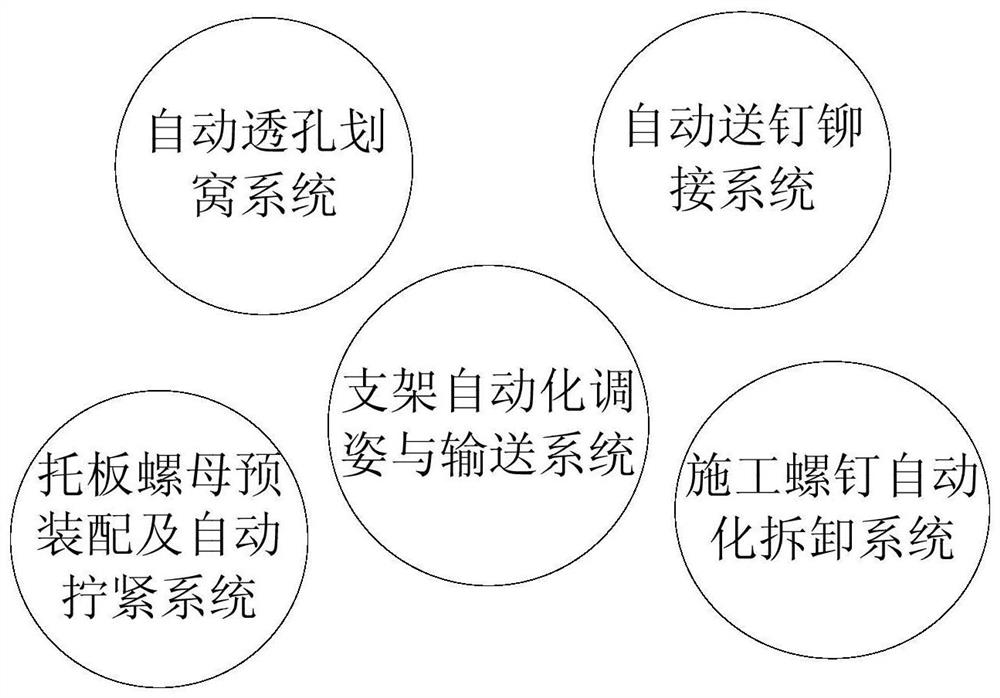

[0042] The device of the present invention includes: an automatic bracket posture adjustment and conveying system 1, an automatic penetrating hole marking system 2, a pallet nut pre-assembly and automatic tightening system 3, an automatic nail feeding riveting system 4 and an automatic removal system 5 for construction screws.

[0043] Automatic attitude adjustment and conveying system 1 realizes automatic grabbing of supports, attitude adjustment of each station support, and support transportation between each station. Automatic penetrating hole marking system 2 realizes bottom hole drilling of support plate nuts on support supports and support plate nuts on support supports. The riveting hole is drilled through the hole, the pallet nut is pre-assembled and the automatic tightening system 3 realizes the automatic loading of the pallet nut, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com