Bridgeless buck-boost power factor correction converter and control system

A power factor correction, buck-boost technology, used in control/regulation systems, DC power input to DC power output, output power conversion devices, etc., can solve problems such as low device utilization, and achieve zero-current shutdown Simple implementation, increased control complexity, and simple system control implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

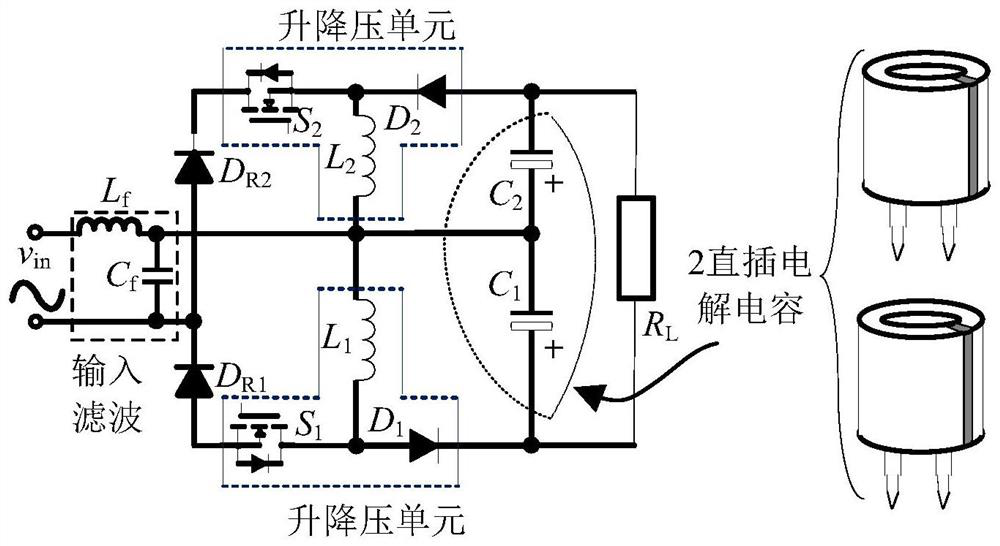

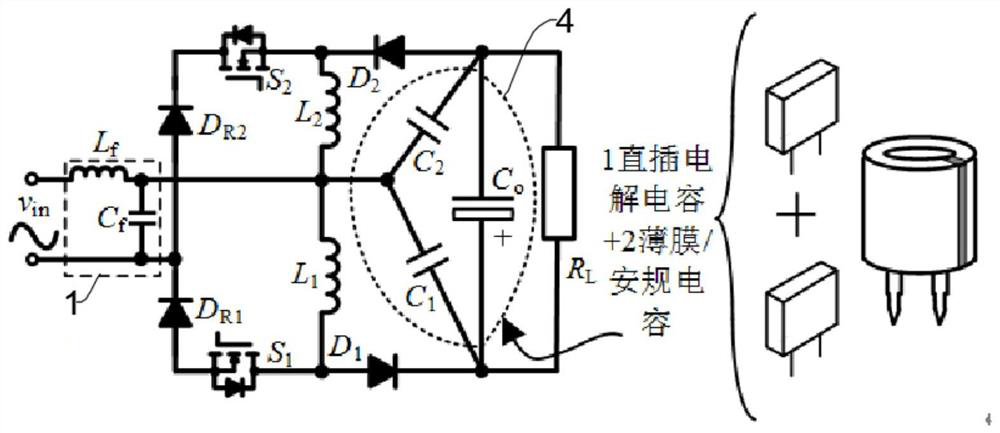

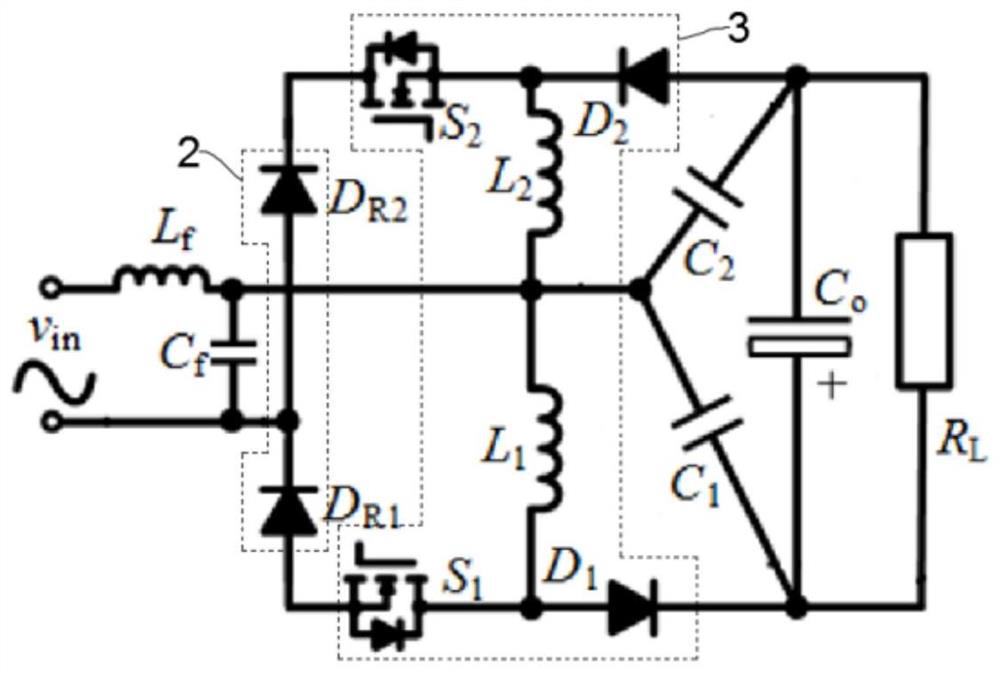

[0041] This embodiment provides a bridgeless buck-boost power factor correction converter, including a conversion circuit, the conversion circuit includes an input filter unit 1, a rectifier unit 2, a buck-boost unit 3 and an output capacitor unit 4 connected in sequence; the above The output capacitor unit 4 includes the output capacitor C 1 , the output capacitance C 2 and main output capacitor C 0 , above the output capacitor C 1 One end of the output capacitor with the above C 2 connected at one end, above the output capacitor C 1 The other end of the above-mentioned buck-boost unit 3 and the main output capacitor C 0 The positive terminal is connected above the output capacitor C 2 The other end of the above-mentioned buck-boost unit 3 and the main output capacitor C 0 The negative terminal connection; the above output capacitor C 1 with the above output capacitor C 2 The interconnection terminals of the above-mentioned buck-boost unit and the 3-input filter unit ...

Embodiment 2

[0047] In this embodiment, the above-mentioned converter includes two working modes, when the AC input v in During zero-cross commutation, the converter works in mode A, when the AC input v in During non-zero-crossing commutation, the converter works in mode B.

[0048] Since the operation of the bridgeless buck-boost PFC converter of the present invention is similar in the positive half cycle and the negative half cycle of the AC input, this embodiment only uses the operation of the positive half cycle as an example to illustrate the working principle of the converter.

[0049] The converter of the present invention application has A, B two kinds of working modes: (1) when the AC input v in At zero-crossing commutation, the converter works in mode A, and working mode A is as follows Figure 3(a) ~ 3(c) Shown; (2) When the AC input v in At the non-zero-crossing commutation place, the converter works in mode B, and the working mode B is as follows Figure 4(a) ~ 4(d) shown....

Embodiment 3

[0065] like Figure 7 As shown, this embodiment provides a control system, including the above-mentioned converter and a control circuit for controlling the converter to realize constant current output, and the control circuit is connected to the output end of the conversion circuit.

[0066] Since the buck-boost PFC converter is commonly used in LED driving devices, the present invention applies a constant current output control method. Wherein the control circuit includes a sampling proportional amplification circuit K i , adder and subtractor, PI parameter operator, comparator and drive circuit; the output terminal of the conversion circuit is in the main output capacitor C 0 with load R L connected between the output current sense resistor R i ;

[0067] The output current sense resistor R i The voltage on the sample is sampled and passed through the proportional amplification circuit K i After adding and subtracting with the reference current I refTo compare, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com