Bean frying process and bean leisure food

A bean and craft technology, applied in the field of bean frying processing, can solve the problems of insufficient crispness, dull color, and unsatisfactory appearance, etc., and achieve the effect of less debris and no burnt crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

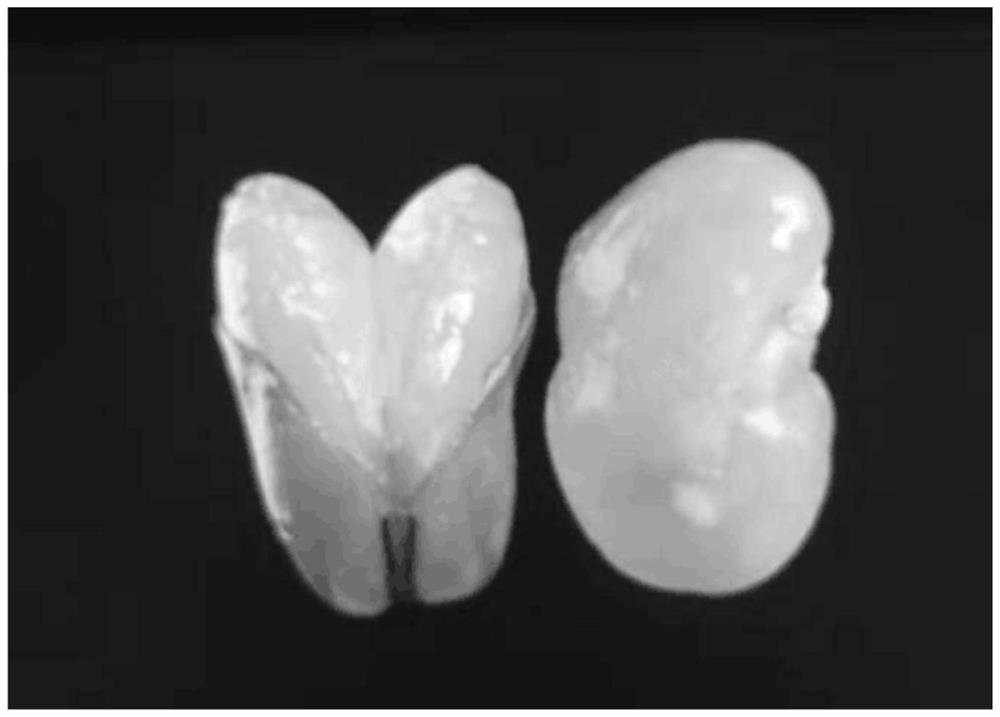

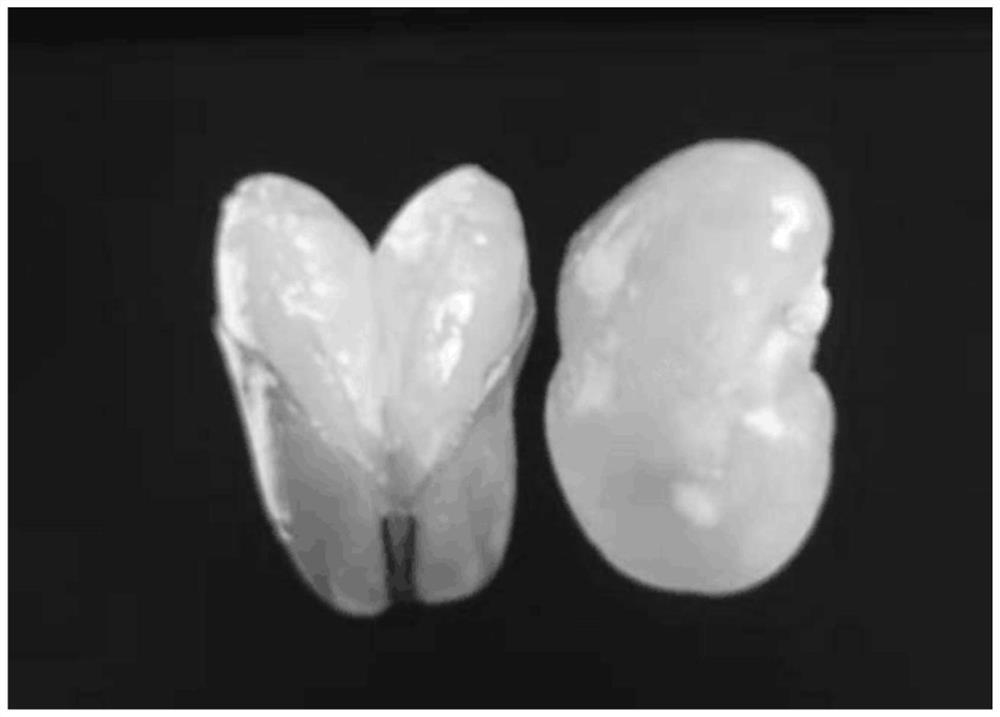

Image

Examples

Embodiment 1

[0017] This embodiment provides a bean fried process comprising the steps as follows:

[0018] 50kg broad bean paste is inserted in 300kg water soaking, as the water weight of the broad bean flap (ie, the immersion water weight loss / drained material (including the water absorption of material) * 100%,) is 45.5%, then remove the pressurization In the fryer, the use of rapeseed oil in a pressurized fryer as a medium and first heated to 130 ° C, set the pressure of 0.05 MPa, then put it broad bean flap, and continued for 150s, then relieve pressure to 0 MPa in 1S. Then, the broad bean paste is transferred to a normal pressure fryer (the medium is also rapeseed oil) at 140 ° C for 12min, and the product is drained and the product is derived and the product has a water content of 3.3%.

Embodiment 2

[0020] This embodiment provides a bean fried process comprising the steps as follows:

[0021] 50kg broad bean paste in 300kg water soaking, when the water bean flap is 50%, then transferred into a pressurized fryer, pressurized frying pan as a medium and first heating to 150 At ° C, the pressure is 0.15 MPa, then put into the broad bean flap, and continuously 100s, then pressure pressure to 0 MPa in 2S, then transfer the broad bean flaps into the normal pressure fryer at 145 ° C for 8 min, remove the Drop the product is drained and removed from the oil, and the water content of the product is 3.5%.

Embodiment 3

[0023] This embodiment provides a bean fried process comprising the steps as follows:

[0024] 50kg broad bean flaps into 300kg water soaking, when the water bean flap is 55%, then transferred into a pressurized fryer, pressurized in a pressurized fryer as a medium and first heating to 180 At ° C, the pressure is 0.35 MPa, then put into the broad bean flap, and last 50s, then pressure pressure to 0.03 MPa in 4S, continue to rapidly pressure to 0, then transfer the broad bean petal into the normal pressure oil fryer at 150 ° C Following 4 min, removed from gray and centrifugally, the product was given, and the product water content was 3.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com