Ultra-low carbon IF molten steel peroxidation treatment method

A treatment method and peroxidation technology, applied in the field of metallurgy, can solve problems such as stable flow, adverse effects on quality assurance customer satisfaction, high quality change rate of cast slabs and cold-rolled finished products, and poor castability of molten steel, etc., to achieve The effect of highlighting the substantial features, reducing the oxygen content, and reducing the amount of aluminum added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

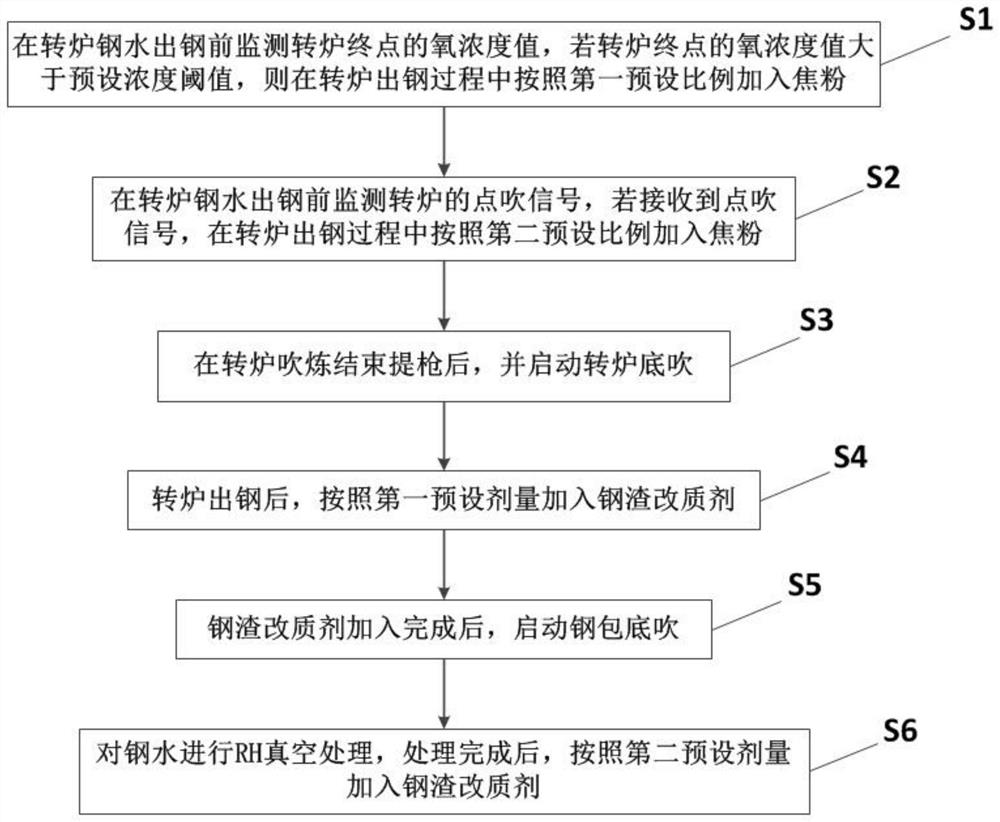

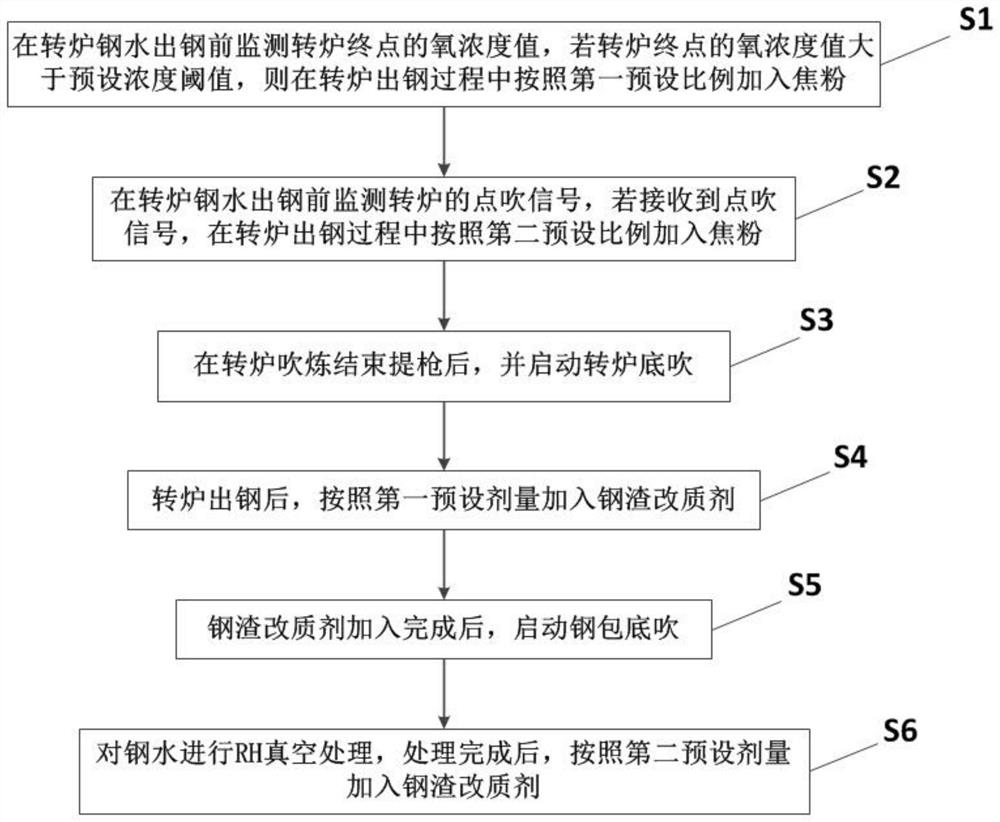

[0036] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0037] Such as figure 1 As shown, the present embodiment discloses a treatment method for ultra-low carbon IF molten steel peroxidation, comprising the steps of:

[0038] S1: Monitor the oxygen concentration value at the end point of the converter before tapping the molten steel in the converter. If the oxygen concentration value at the end point of the converter is greater than the preset concentration threshold, add coke powder according to the first preset ratio during the tapping process of the converter.

[0039] This step is specifically: when monitoring the situation that terminal oxygen is greater than 800ppm before molten steel tapping of converter, add coke powder and carry out deoxidation in the process of converter tapping, and the amount of coke powder added is according to the oxygen concentration value of converter terminal point every in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com