A double evaporator condenser loop heat pipe

A loop heat pipe and double evaporator technology, applied in the field of loop heat pipes, can solve the problems of inability to realize multi-heat source transfer, difficulty in dissipating heat from different heat sources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

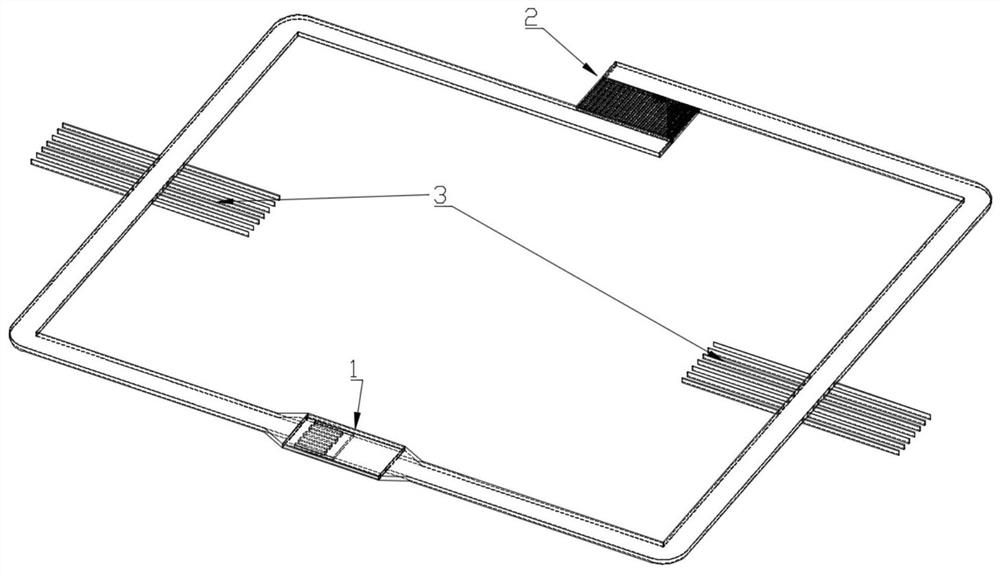

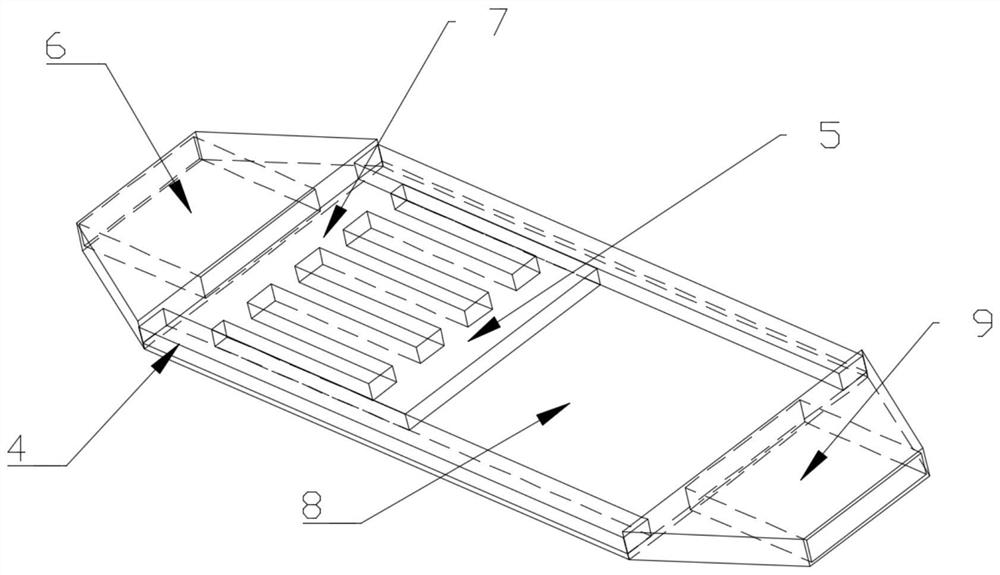

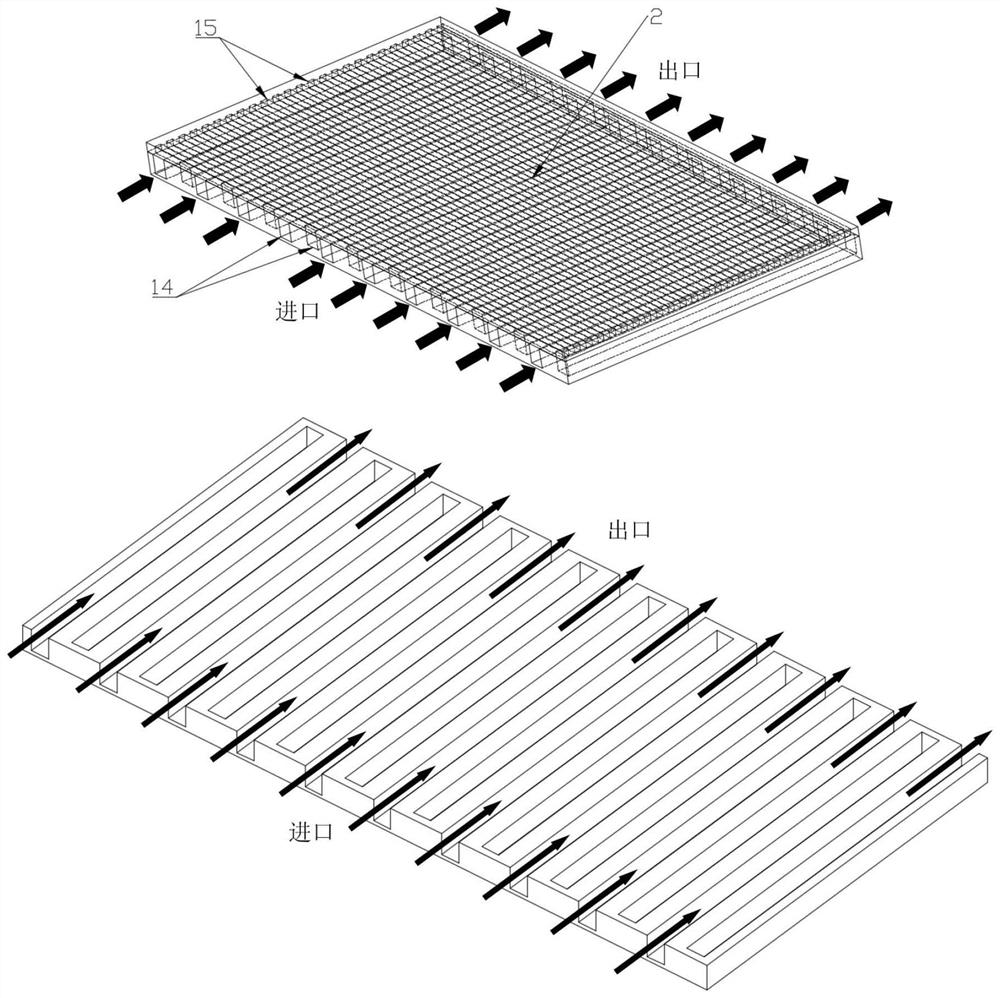

[0036] like figure 1 , 4 As shown, a double evaporator condenser loop heat pipe includes an evaporator 1, a radiator 2 and a condenser 3. The condenser includes two condensers, namely a first condenser 31, a second condenser 32, and the evaporator 1 It is connected with the first condenser 31 through the first steam pipeline 10, the first condenser 31 and the radiator 2 are connected through the first liquid pipeline 11, and the radiator 2 and the second condenser 32 are connected through the second pipeline 12 (No. The two pipelines may be steam pipelines or thermal fluid pipelines) connected, and the second condenser 32 and the evaporator 1 are connected through the second liquid pipeline 13 .

[0037]In the present invention, two different heat absorbing elements (evaporator, radiator) and condenser are arranged in one loop heat pipe, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com