Thin-film solar cell and method of making the same

A technology of solar thin film and manufacturing method, which is applied in the direction of circuits, electrical components, photovoltaic power generation, etc., can solve the problems of increasing environmental burdens, achieve the effects of improving photoelectric conversion efficiency, reducing Cl content, and reducing the doping amount of group V elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

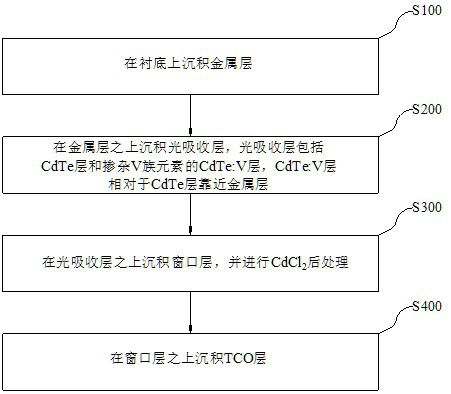

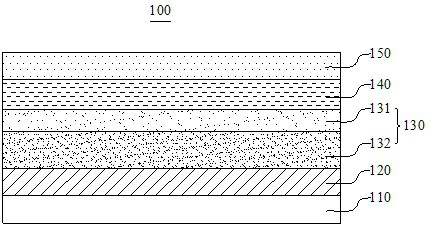

[0028] figure 1 It is a schematic diagram of a solar thin film cell with a top liner structure in the prior art. like figure 1 As shown in the figure, the solar thin film cell has a top liner structure, that is, a TCO layer, a window layer, a light absorption layer (including CdTe) and a metal layer are sequentially formed on the substrate during fabrication. The specific production process includes:

[0029] 1) Fabricate the TCO layer on the substrate;

[0030] 2) Make a window layer on the TCO layer;

[0031] 3) depositing CdTe on the window layer to form a light absorbing layer;

[0032] 4) After the light absorption layer is formed, CdCl 2 post-processing;

[0033] 5) Weak acid etching to remove the oxide layer on the light absorption layer;

[0034] 6) Deposit a metal layer as the back electrode.

[0035] In this process flow, the CdCl after the formation of the light absorbing layer containing CdTe 2 The post-processing process is to obtain high photoelectric co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com