Preparation method of catalyst for producing aromatic hydrocarbon, catalyst and application thereof

A technology for catalysts and aromatics, which is used in the preparation of catalysts for the production of aromatics, catalysts and their applications, and can solve problems such as increased corrosion of equipment and low catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

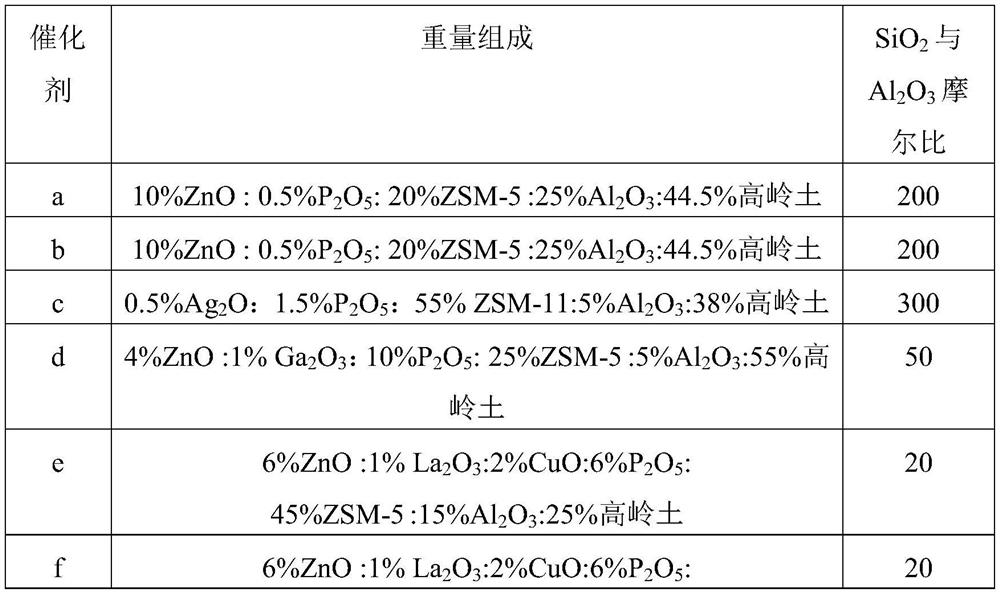

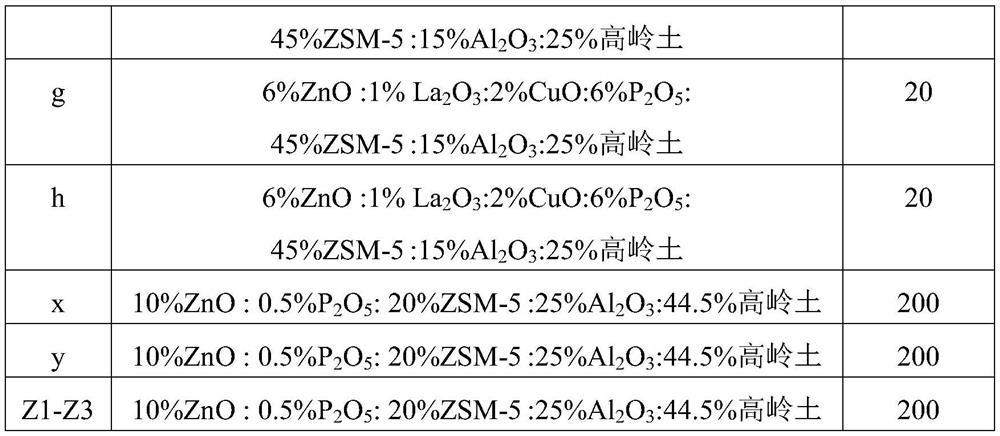

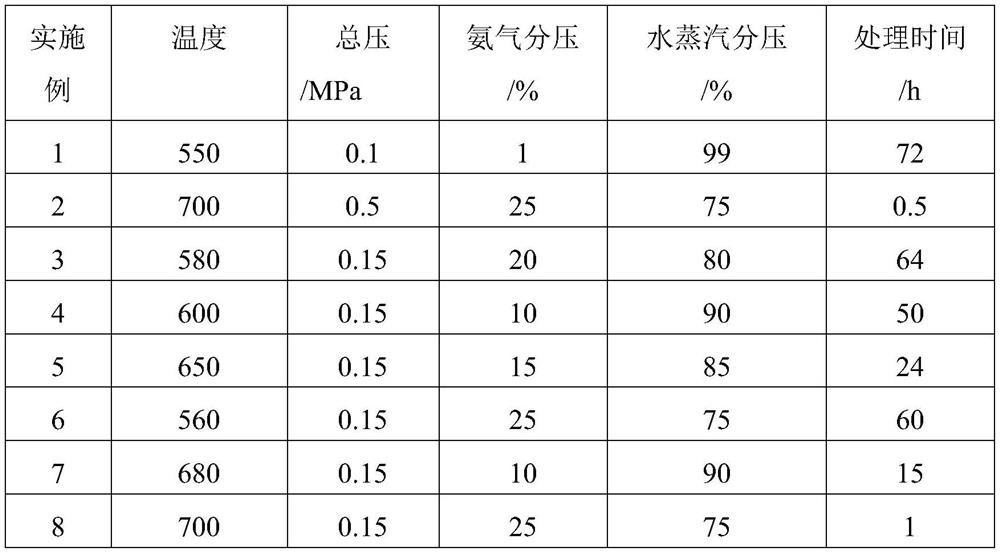

Embodiment 1

[0044] With 80 grams of ZSM-5 molecular sieves (the molar ratio of silica and alumina=200), 476.2 grams of Al sol (21wt% Al 2 o 3 ), 178 gram of kaolin and 1500 gram of water are mixed uniformly to obtain slurry, and the slurry is spray-dried to prepare microsphere SP1 with an average particle diameter of 71.5 microns, and microsphere carrier ZT1 is prepared through 550 ℃ of roasting for 4 hours, and its chlorine content is 2720ppm.

[0045] Take 189 grams of carrier ZT1, impregnate it with 140 grams of aqueous solution containing 1.62 grams of phosphoric acid, age at room temperature for 24 hours, dry at 120°C for 12 hours, and bake at 600°C for 3.5 hours to obtain the P-modified carrier PZT1.

[0046] DCL-1 was obtained after PZT1 was treated for 72 hours at 550°C, the total pressure was normal pressure, the partial pressure of ammonia was 1%, and the rest was water vapor.

[0047] Take 90 grams of carrier DCL-1, impregnate it with 90 grams of an aqueous solution containing...

Embodiment 2

[0049] Carrier DCL2 was obtained after PZT1 was treated at 700° C., total pressure 0.5 MPa, ammonia partial pressure 20%, and the rest was water vapor for 0.5 h.

[0050] Take 189 grams of carrier DCL2, impregnate with 90 grams of an aqueous solution containing 36.7 grams of zinc nitrate, age at room temperature for 24 hours, dry at 120° C. for 12 hours, and roast at 600° C. for 3.5 hours to obtain catalyst b with a chlorine content of 450 ppm.

Embodiment 3

[0052] With 100 grams of ZSM-5 molecular sieves (the molar ratio of silica and alumina=300), 93.2 grams of Al sol (21wt% Al 2 o 3 ), 152 gram of kaolin and 2200 gram of water are mixed uniformly to obtain the slurry, and the slurry is spray-dried to prepare the microsphere SP3 with an average particle diameter of 72.8 microns, and prepares the microsphere carrier ZT3 through 550 ℃ of roasting for 4 hours, and its chlorine content is 1630ppm.

[0053] Take 196 grams of carrier ZT3, impregnate it with 150 grams of aqueous solution containing 4.9 grams of phosphoric acid, age at room temperature for 24 hours, dry at 120°C for 12 hours, and then bake at 600°C for 3.5 hours to obtain the P-modified carrier PZT3.

[0054] DCL-3 was obtained after PZT3 was treated for 64 hours at 580°C, total pressure 0.15MPa, ammonia partial pressure 25%, and the rest was water vapor.

[0055] Take 99.5 grams of carrier DCL-3, impregnate it with 90 grams of an aqueous solution containing 0.73 grams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com