Semiconductor device and method of forming the same

A technology for semiconductors and devices, applied in the field of semiconductor devices and their formation, can solve problems such as affecting the performance of semiconductor devices, short-circuiting of contact structures, etc., and achieve the effects of improving the etching selection ratio, reducing the ratio, and avoiding short-circuit problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention provide a semiconductor device and a method for forming the same, which will be described in detail below with reference to the accompanying drawings.

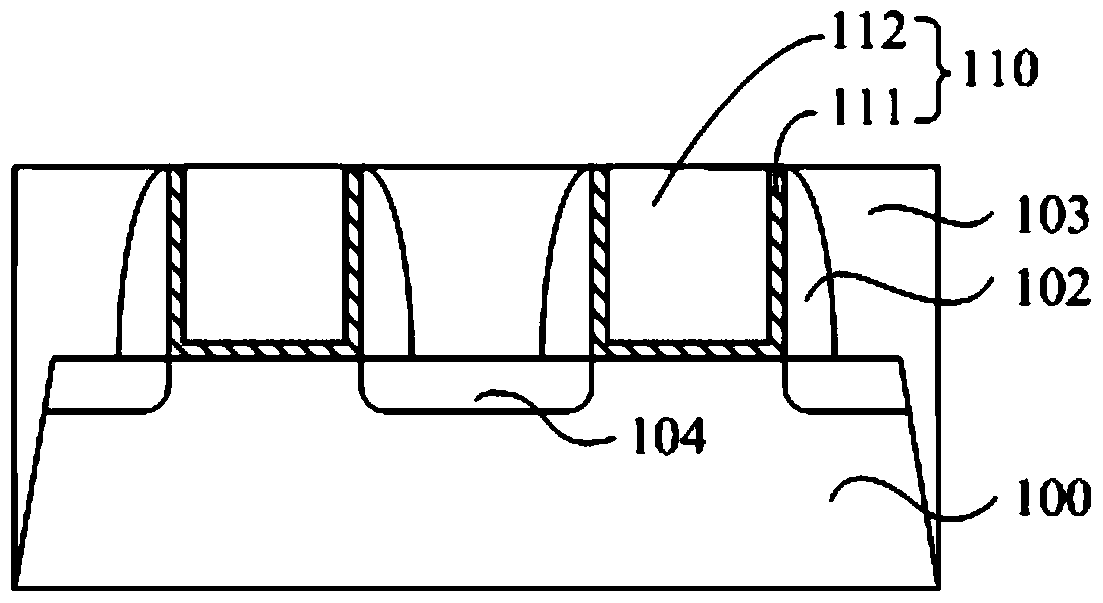

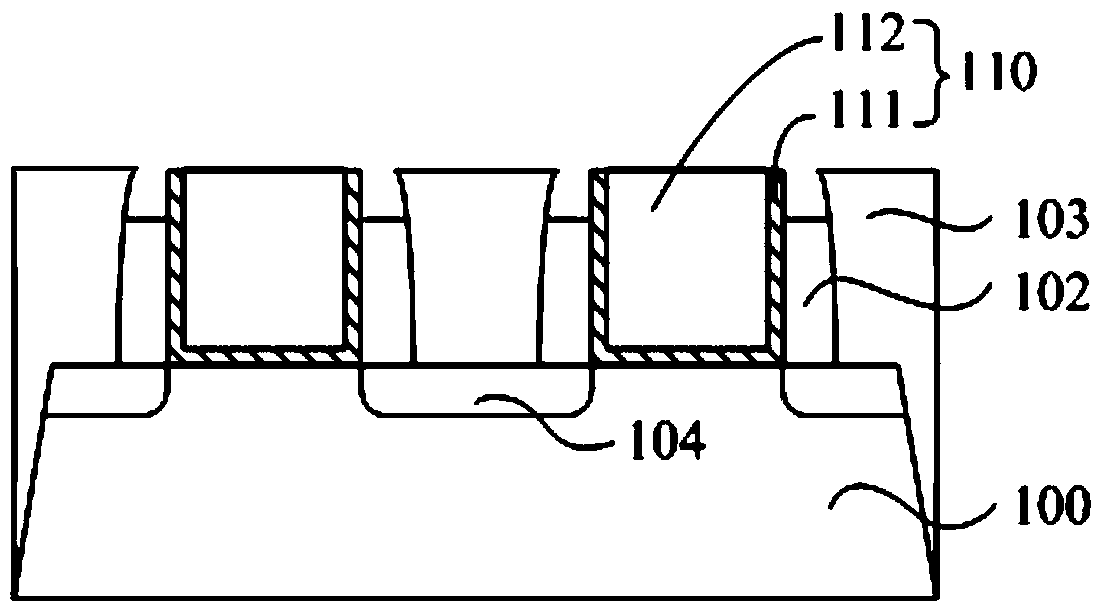

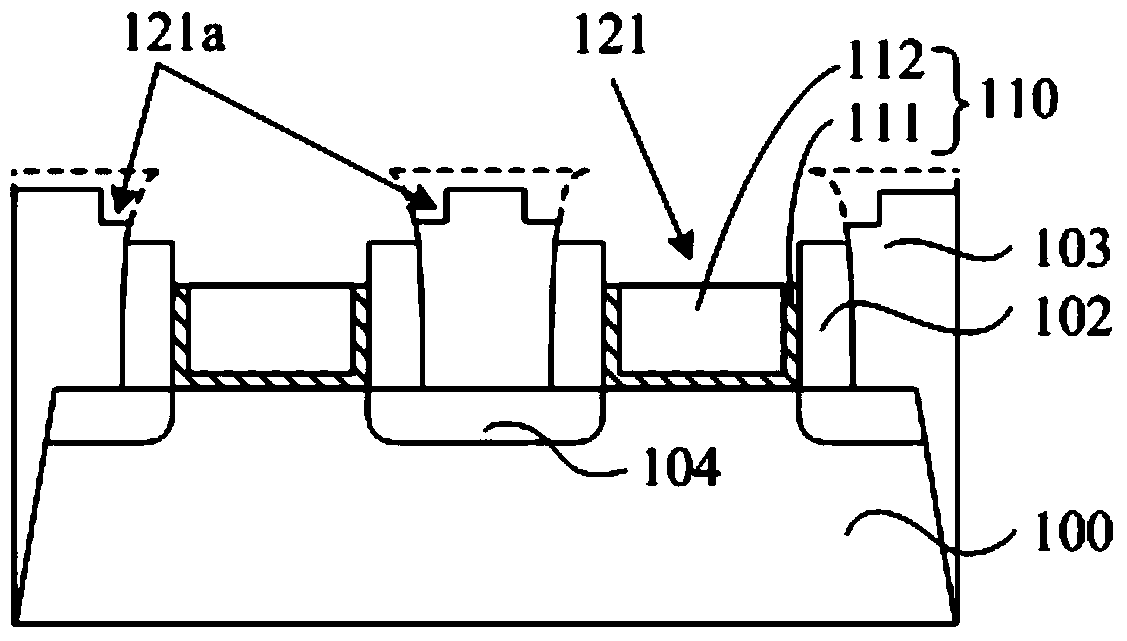

[0035] Figure 1 to Figure 7 is a schematic cross-sectional structure diagram of the intermediate structure of the method for forming a semiconductor device according to the first embodiment of the present invention.

[0036] refer to figure 1 , providing a substrate 100, the surface of the substrate 100 is formed with a gate structure 110, a first dielectric layer 103, and spacers 102 on both sides of the gate structure 110, wherein the gate structure 110 and the spacers 102 are located on the In the first dielectric layer 103, and the top surfaces of the gate structure 110 and the spacer 102 are flush with the top surface of the first dielectric layer 103, the first dielectric layer 103 has the same structure as the sidewall 102 On adjacent side surfaces, source / drain regions 104...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com