Construction method for reinforcing and repairing damaged coal bunker at shaft bottom

A construction method and coal bunker technology, applied in shaft lining, shaft equipment, earthwork drilling, etc., can solve the problems of increasing the service life of coal bunkers and low support strength, so as to reduce labor intensity, increase mine capacity, prevent The effect of the destruction of the coal bunker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

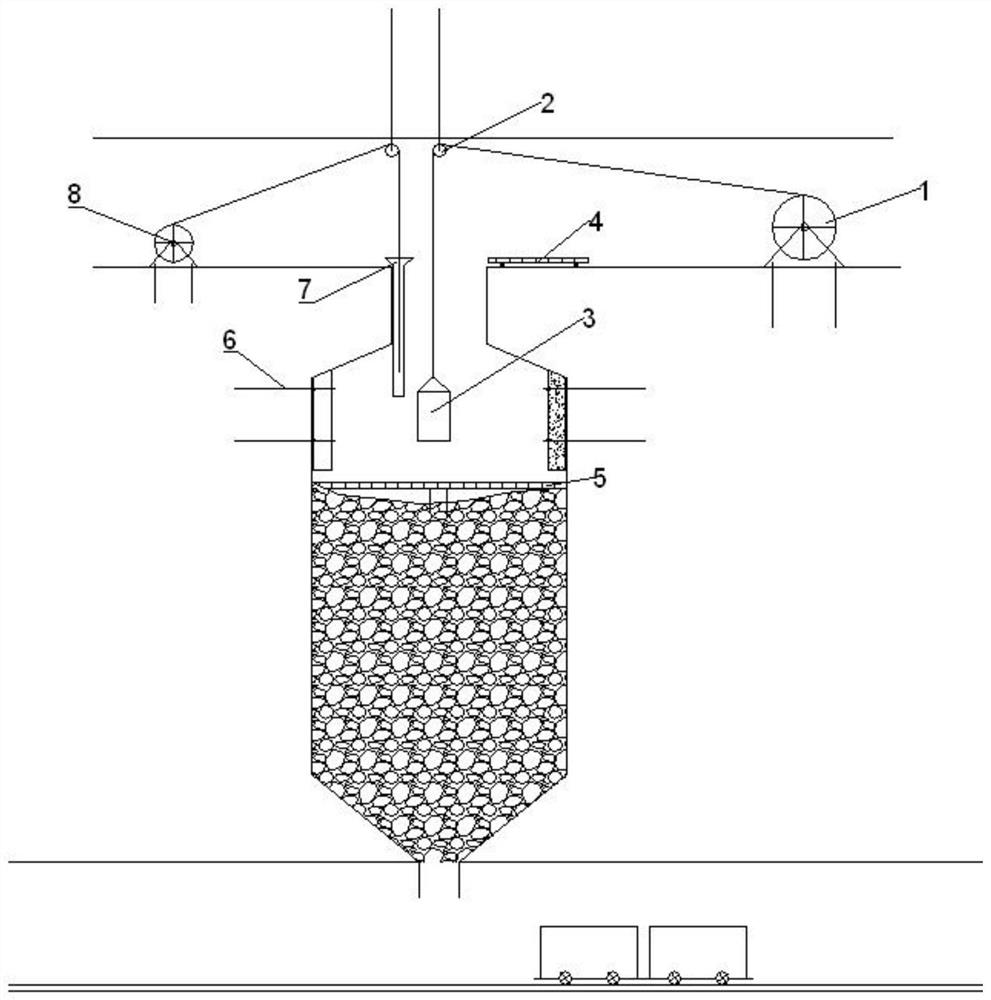

[0026] Such as figure 1 As shown, a kind of well bottom damaged coal bunker reinforcement and repair construction method provided by the present invention is carried out according to the following steps:

[0027] Step 1. Coal bunker mouth measures engineering: hoisting system, compressed air supply system, power supply system, coal bunker sealing plate facilities and equipment are accurate, installed and non-standard parts are processed, and the coal storage to be repaired is full of coal. Specifically, the winch 1 is fixed on the foundation surface around the upper mouth of the coal bunker 10, and the pulley 2 is fixed on the roadway top wall opposite to the upper mouth of the coal bunker 10. The steel wire rope on the hoist 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com