Meal replacement snack and preparation method thereof

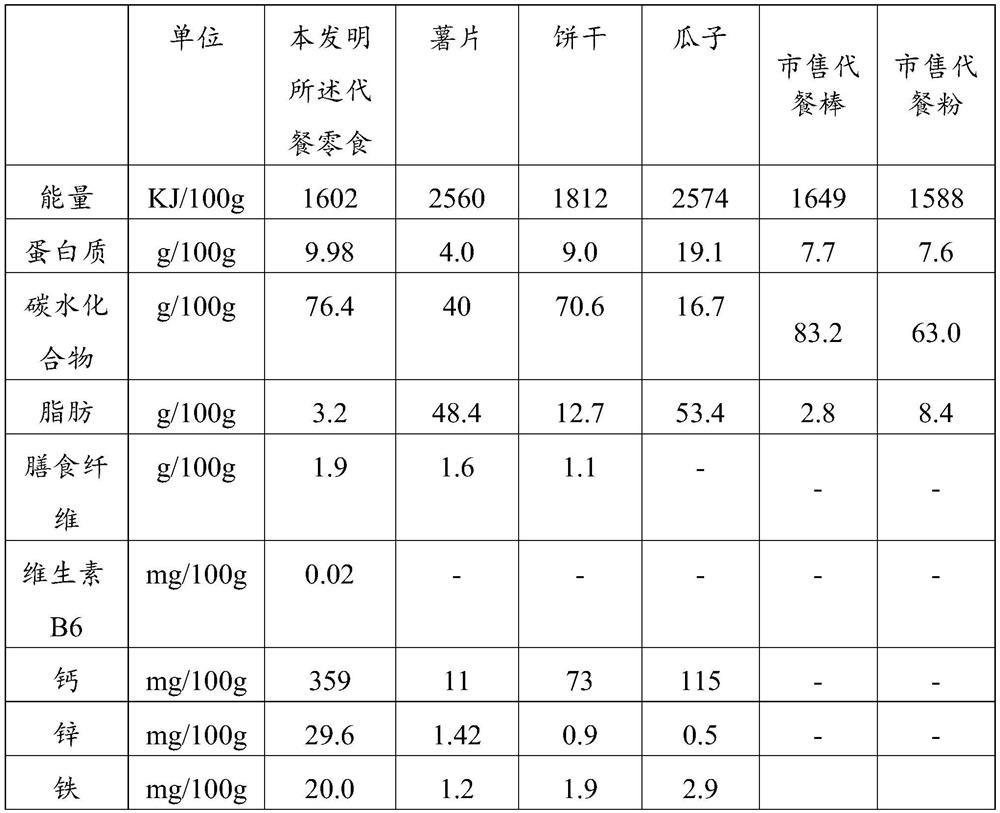

A technology for snacks and meal replacements, applied in food science and other directions, can solve the problems of unbalanced nutrition, insufficient food, heavy taste, etc., and achieve the effect of balanced nutritional components and good satiety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The meal replacement snack described in Example 1 includes the following raw materials by weight: 5 parts by weight of wheat germ, 3 parts by weight of rice bran, 60 parts by weight of japonica broken rice, 2 parts by weight of white sesame seeds, 2 parts by weight of black sesame seeds, and 2 parts by weight of crushed peanuts. parts by weight, 4 parts by weight of oats, 3 parts by weight of sorghum, 5 parts by weight of red rice, 5 parts by weight of black rice, and 3 parts by weight of millet.

[0030] The preparation method of the meal replacement snack described in embodiment 1, comprises the following steps:

[0031] (1) mixing and pulverizing each raw material to obtain a mixture with a fineness of 90 meshes;

[0032] (2) Add water to the mixture, and ensure that the moisture content of the mixture after adding water is 15%, and then extrude and puff, and the temperature of the first zone from the feed end to the discharge end of the extrusion and puffing is 50 °...

Embodiment 2

[0034] The meal replacement snack described in Example 2 includes the following raw materials by weight: 6 parts by weight of wheat germ, 3 parts by weight of rice bran, 62 parts by weight of japonica broken rice, 2 parts by weight of white sesame seeds, 2 parts by weight of black sesame seeds, and 2 parts by weight of crushed peanuts. parts by weight, 4 parts by weight of oats, 3 parts by weight of sorghum, 6 parts by weight of red rice, 5 parts by weight of black rice, and 3 parts by weight of millet.

[0035] The preparation method of the meal replacement snack described in embodiment 2, comprises the following steps:

[0036] (1) mixing and pulverizing each raw material to obtain a mixture with a fineness of 100 meshes;

[0037] (2) Add water to the mixture, and ensure that the moisture content of the mixture after adding water is 18%, and then extrude and puff. The temperature of the first zone from the feed end to the discharge end of the extrusion and puffing is 55 ° C,...

Embodiment 3

[0039] The meal replacement snack described in Example 3 includes the following raw materials by weight: 7 parts by weight of wheat germ, 4 parts by weight of rice bran, 65 parts by weight of japonica broken rice, 2 parts by weight of white sesame seeds, 2 parts by weight of black sesame seeds, and 2 parts by weight of crushed peanuts. parts by weight, 5 parts by weight of oats, 3.5 parts by weight of sorghum, 6 parts by weight of red rice, 6 parts by weight of black rice, and 4 parts by weight of millet.

[0040] The preparation method of the meal replacement snack described in embodiment 3, comprises the following steps:

[0041] (1) mixing and pulverizing each raw material to obtain a mixture with a fineness of 115 objects;

[0042] (2) Add water to the mixture, and ensure that the moisture content of the mixture after adding water is 18%, and then extrude and puff. The temperature of the first zone from the feed end to the discharge end of the extrusion and puffing is 60 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com