Preparation method of selenium-rich cooked Chinese chestnut powder suitable for industrial production

The technology of chestnut powder and chestnut is applied in the preparation method of peptide, chemical instrument and method, application and other directions, which can solve the problems of reducing selenium content, being unfavorable for commercial promotion, and high selenium loss rate, achieving high extraction rate and extending the chestnut industry. chain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing cooked selenium-enriched chestnut powder suitable for industrialized production, comprising the following steps:

[0023] (1) Preparation of chestnut powder: take chestnuts as raw materials, shell, peel and slice chestnuts to obtain thin slices of chestnut kernels, put the thin slices of chestnut kernels into the color protection solution to soak for color protection, and remove the thin slices of chestnut kernels after soaking , leaving the color-protecting solution, and then steaming and slaking the chestnut kernel slices; then mixing and beating the cured chestnut slices and the color-protecting solution according to the ratio of material to liquid at 1g:5mL; using drum drying to obtain cooked chestnut powder; in the color-protecting solution It contains 0.25% disodium stannous citrate, 0.35% EDTA-2Na, 0.30% chitosan, 0.50% L-cysteine, and 0.50% mass fraction. 0.15% citric acid;

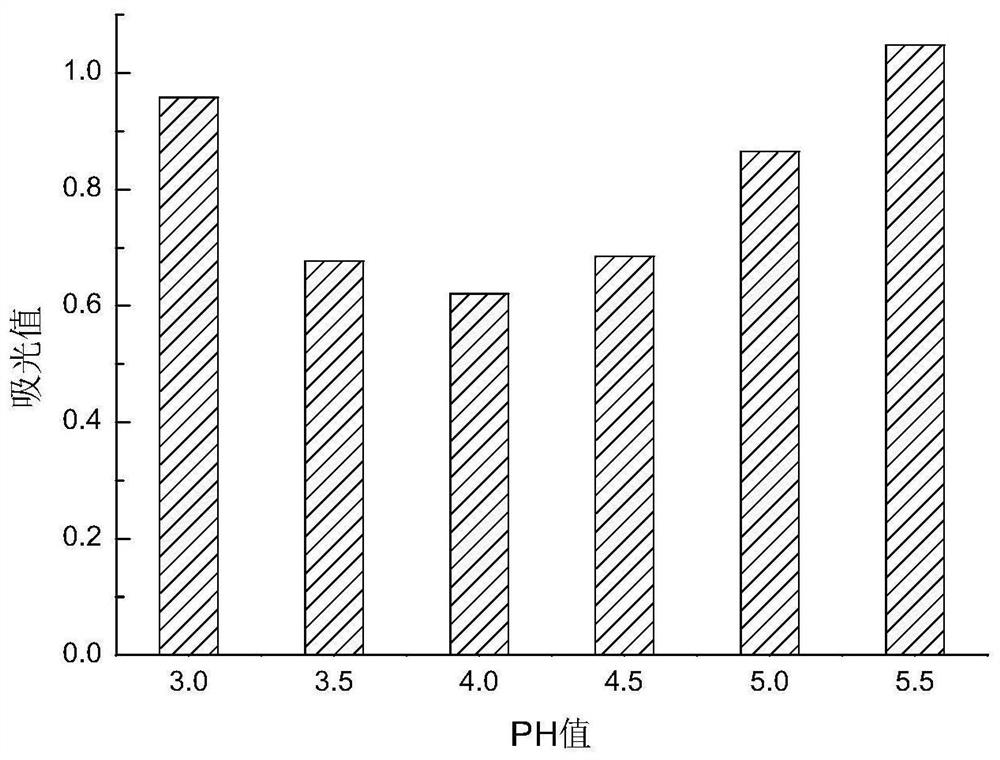

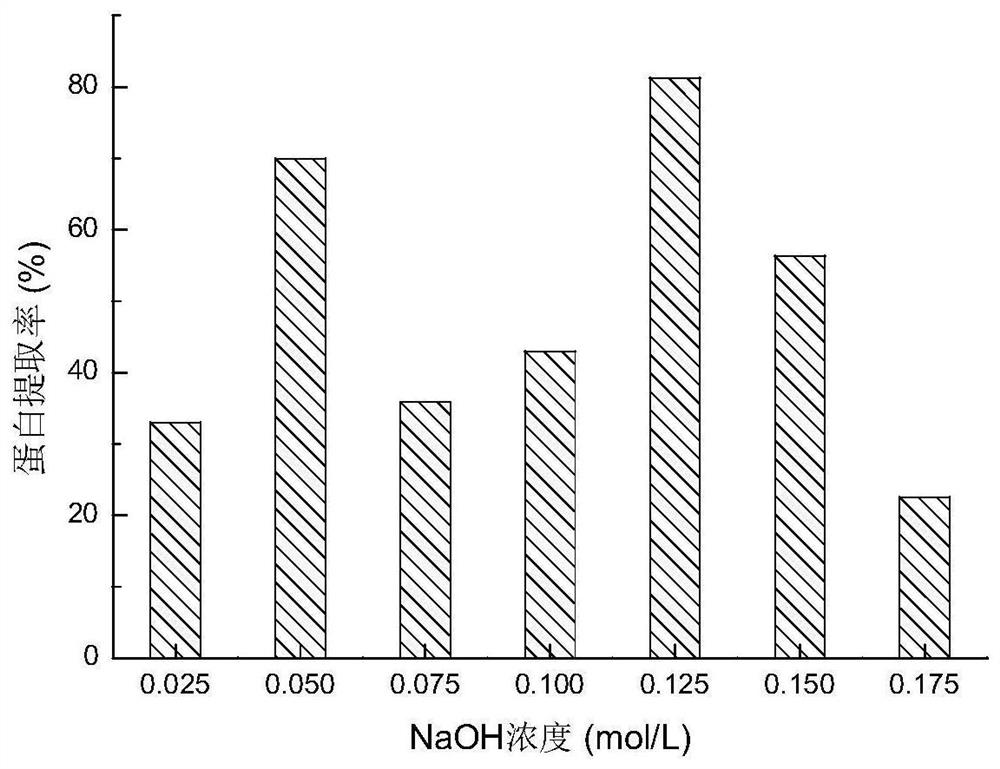

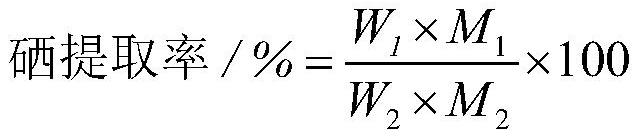

[0024] (2) Selenium-enriched protein extraction: Weigh 50g of c...

Embodiment 2

[0027] A method for preparing cooked selenium-enriched chestnut powder suitable for industrialized production, comprising the following steps:

[0028] (1) Preparation of chestnut powder: take chestnuts as raw materials, shell, peel and slice chestnuts to obtain thin slices of chestnut kernels, put the thin slices of chestnut kernels into the color protection solution to soak for color protection, and remove the thin slices of chestnut kernels after soaking , leaving the color-protecting solution, and then steaming and slaking the chestnut kernel slices; then mixing and beating the cured chestnut slices and the color-protecting solution according to the ratio of material to liquid at 1g:5mL; using drum drying to obtain cooked chestnut powder; in the color-protecting solution It contains 0.25% disodium stannous citrate, 0.35% EDTA-2Na, 0.30% chitosan, 0.50% L-cysteine, and 0.50% mass fraction. 0.15% citric acid;

[0029] (2) Selenium-enriched protein extraction: Weigh 50g of c...

Embodiment 3

[0032] A method for preparing cooked selenium-enriched chestnut powder suitable for industrialized production, comprising the following steps:

[0033] (1) Preparation of chestnut powder: take chestnuts as raw materials, shell, peel and slice chestnuts to obtain thin slices of chestnut kernels, put the thin slices of chestnut kernels into the color protection solution to soak for color protection, and remove the thin slices of chestnut kernels after soaking , leaving the color-protecting solution, and then steaming and slaking the chestnut kernel slices; then mixing and beating the cured chestnut slices and the color-protecting solution according to the ratio of material to liquid: 1g:5mL; using drum drying to obtain cooked chestnut powder; in the color-protecting solution Containing disodium stannous citrate that mass fraction is 0.25%, EDTA-2Na that mass fraction is 0.35%, chitosan that mass fraction is 0.30%, L-cysteine that mass fraction is 0.50%, mass fraction is 0.15% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com