Efficient industrial robot processing energy-saving trajectory planning method under high-order complex constraint condition

A technology of industrial robots and constraint conditions, applied in metal processing, metal processing equipment, metal processing machine parts, etc. Industrial robots minimize energy or time trajectory planning methods to achieve the effects of reducing planning time, efficient calculations, and practical calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

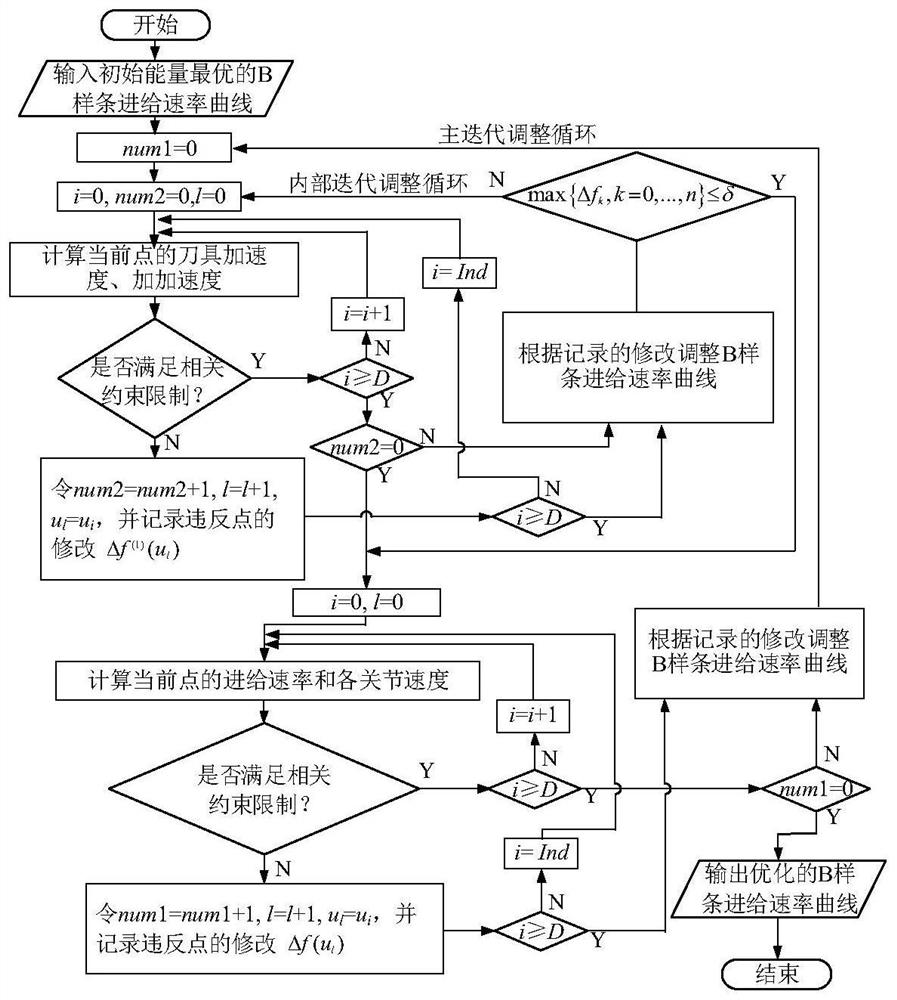

[0139] An efficient energy-saving trajectory planning method for industrial robot processing under high-order complex constraints, including the following steps:

[0140] 1) Fitting the original tool path curve with non-uniform rational B-splines (NURBS), and discretizing the tool path curve to obtain D+1 path sampling points, the steps include:

[0141] 1.1) With normalized arc length u=s / s Σ As a parameter, NURBS curve fitting is performed on the original tool path to obtain the NURBS tool path curve;

[0142] 1.2) Discretize the tool path curve into D microelement paths according to the equal parameter Δu Obtain D+1 path sampling path points {u 1 ,...,u i ,...,u D}, which is also used as the subsequent constraint judgment point.

[0143] 2) Planning the reference feed rate trajectory, including:

[0144] 2.1) Under the speed constraint condition, calculate the maximum feasible speed of D+1 path sampling points;

[0145] 2.2) Obtain the time-optimal feed rate traject...

Embodiment 2

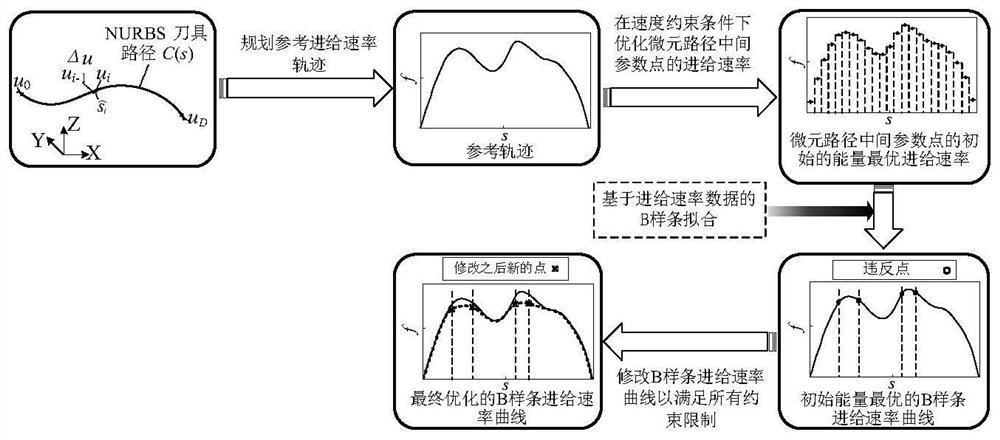

[0264] An efficient energy-saving trajectory planning method for industrial robot processing under high-order complex constraints, including the following steps (for the process see figure 2 ):

[0265] 1) NURBS curve fitting of the tool path: take the normalized arc length u as a parameter, use the NURBS curve to define the tool path curve, and discretize the path curve and other parameters Δu into D micro-element paths (i=1, . . . , D), obtain D+1 waypoints.

[0266] 2) Planning the reference feed rate trajectory: Considering the speed-related constraints, calculate the maximum feasible speed of D+1 path points, obtain the time-optimal feed rate trajectory under the speed constraints, and use it as the reference trajectory.

[0267] 3) Obtain the B-spline feed rate curve with optimal initial energy: calculate the cubic polynomial energy consumption characteristic model of each microelement path under the reference trajectory ( is the average feed rate, for the refe...

Embodiment 3

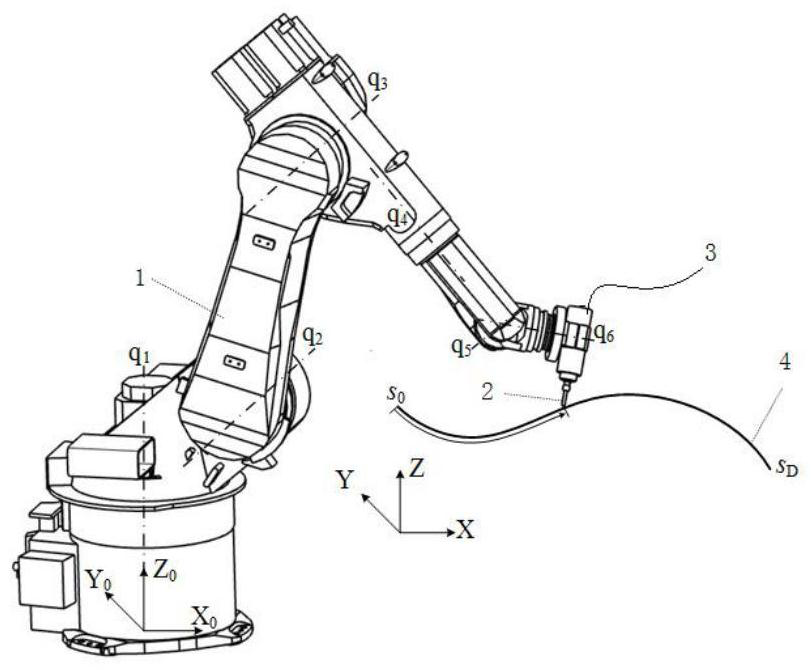

[0335] The flow chart of the present invention is shown in figure 2 , select an industrial robot processing system as the experimental object, see figure 1 (The industrial robot processing system includes industrial robot 1, spindle system 3, and tool 2), the tool path 4 of the experimental object is shown in Image 6 As shown in Fig. 1, the efficient high-order and complex constraints of the industrial robot processing energy-saving trajectory planning method for the experimental object, the steps are as follows:

[0336] First, the tool path curve is defined as a function of the normalized arc length u by using the NURBS curve, and the path curve and other parameters Δu are discretized into D micro-element paths Obtain D+i waypoints. D=551.

[0337] The second step is to calculate the maximum feasible feed rate of D+1 path points under the consideration of speed-related constraints, and obtain the time-optimal feed rate trajectory under the speed constraints, and use it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com