Method for reinforcing the transverse overall performance of prefabricated hollow slab girder

A hollow slab girder and integral technology, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as hinge cracking, achieve the effects of prolonging service life, increasing beam cross-section, and strengthening overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

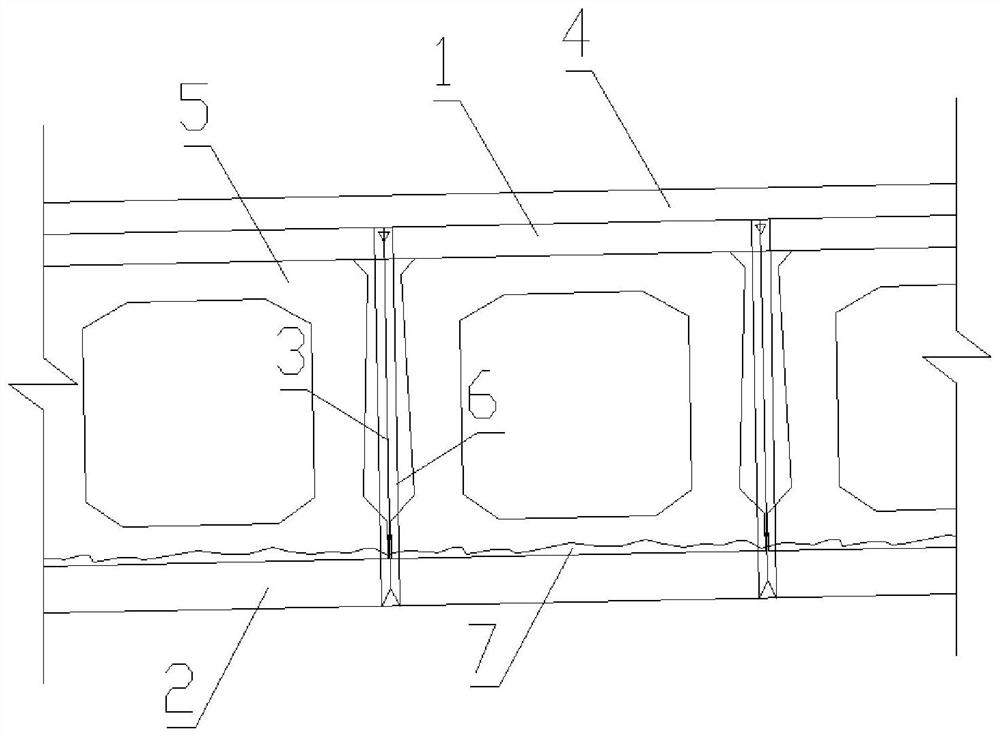

[0015] A method of strengthening the transverse overall performance of prefabricated hollow slab girders, such as figure 1 As shown, the bridge deck pavement 4 of the existing hollow slab girder 5, the ordinary cast-in-place concrete layer, and the carbonized concrete layer 7 at the bottom are first chiseled out, and then the hinge joints on the existing hollow slab girder 5 are vertically spaced at certain distances. Drill out the mounting holes for the vertical prestressing system 3, avoid the slab girder reinforcement when processing the mounting holes, and then bind the upper and lower ultra-high performance reinforced concrete cast-in-place slabs (1 and 2) steel bars, pre-embed the lower end anchors and steel bars of the vertical prestressing system 3, and then pour the upper and lower ultra-high performance reinforced concrete cast-in-situ slabs (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com