Solar photovoltaic sound barrier based on micro-through-hole foamed ceramic plate

A foam ceramic plate and micro-through-hole technology, which is applied in the direction of solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of limited practicality and narrow application range, achieve good economic benefits, realize intelligence, and realize The effect of maximum utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

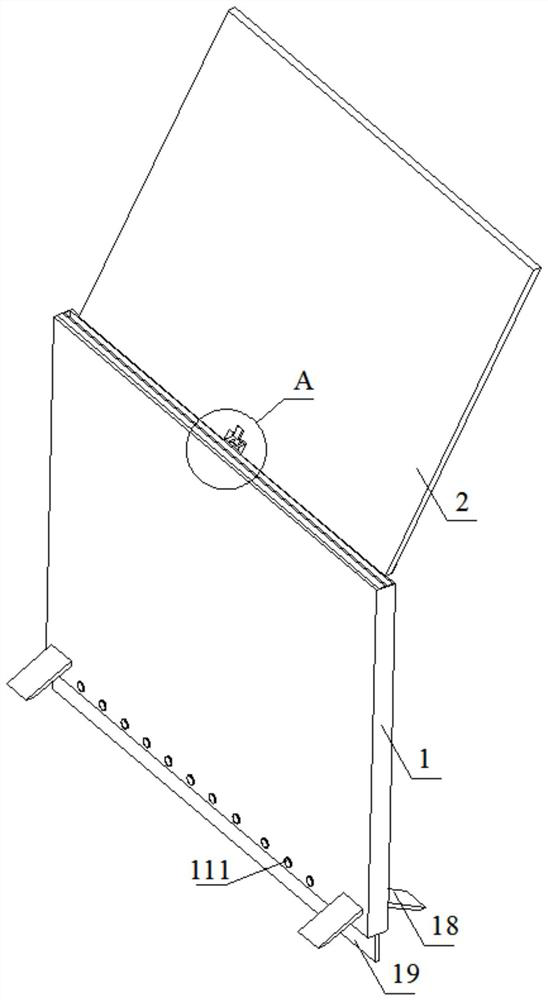

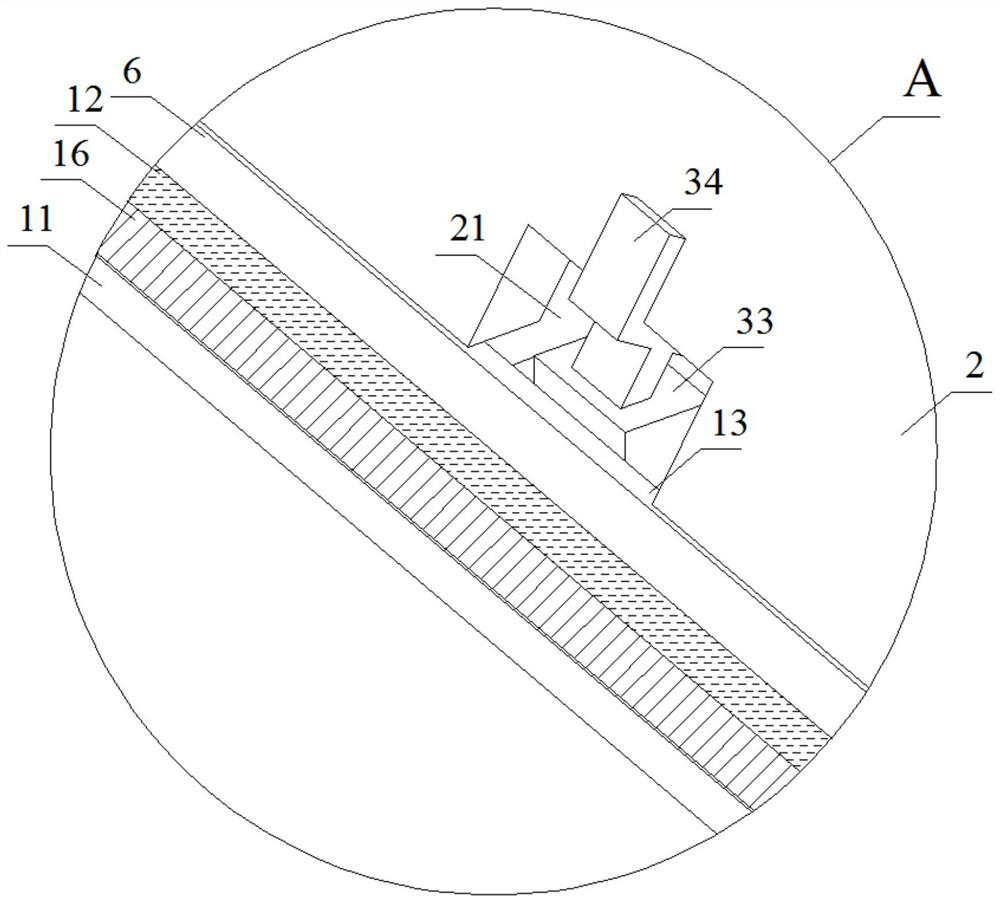

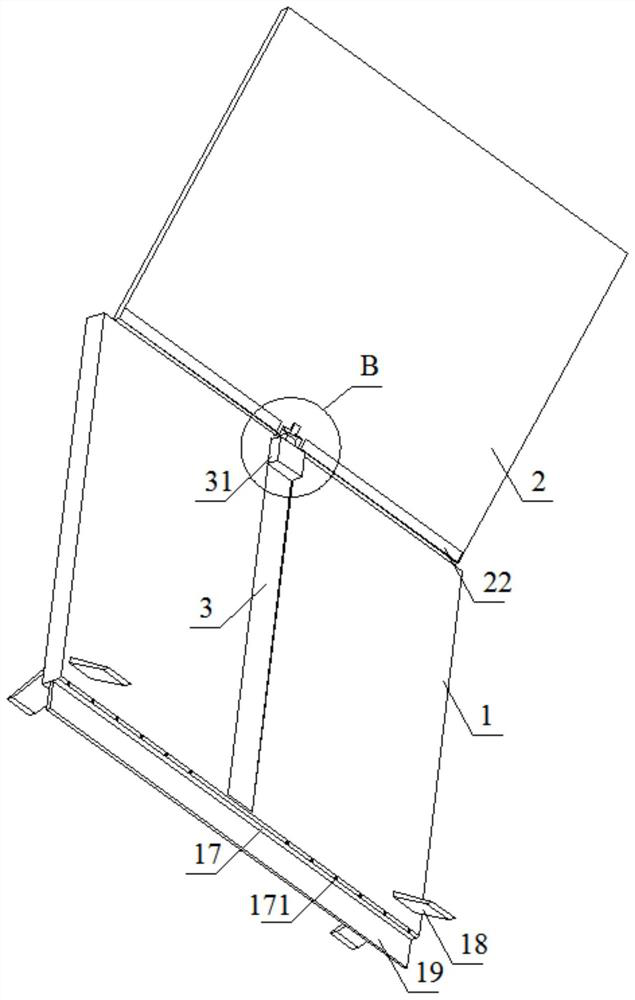

[0035] like Figure 1-4 , 6, a solar photovoltaic sound barrier based on micro-through-hole foamed ceramic plates, including a composite sound-absorbing panel 1 and a solar panel 2, the solar panel 2 is a commercially available double-sided solar panel, and the solar panel 2 is located in the composite sound-absorbing panel The outer surface of the board 1 is slidably connected with the composite sound-absorbing board 1, and the composite sound-absorbing board 1 is sequentially provided with an aluminum-plastic board 11 with a thickness of 1.5 mm, a micro-through-hole ceramic board 12 with a thickness of 22 mm, and a plated board with a thickness of 1.5 mm. A first cavity 14 for water storage is provided between the zinc steel plate 13, the aluminum-plastic plate 11 and the micro-through-hole ceramic plate 12, and a second cavity 15 is provided between the micro-through-hole ceramic plate 12 and the galvanized steel plate 13, The top of the first cavity 14 is provided with a w...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, the difference lies in that the thickness of each layer in the composite sound-absorbing panel 1 is different.

[0042] like Figure 1-4 , 6, a solar photovoltaic sound barrier based on micro-porous ceramic foam boards, including a composite sound-absorbing panel 1 and a solar panel 2, the solar panel 2 is located on the outer side of the composite sound-absorbing panel 1 and is connected to the composite sound-absorbing panel 1 Sliding connection, the composite sound-absorbing panel 1 is sequentially provided with an aluminum-plastic plate 11 with a thickness of 1mm, a ceramic plate with micro-through holes 12 with a thickness of 20mm, and a galvanized steel plate 13 with a thickness of 1mm. A first cavity 14 for water storage is provided between the plates 12, a second cavity 15 is provided between the micro-through-hole ceramic plate 12 and the galvanized steel plate 13, and a water filter plate 16 is provided on...

Embodiment 3

[0044] This embodiment is basically the same as Embodiment 1, the difference lies in that the thickness of each layer in the composite sound-absorbing panel 1 is different.

[0045] like Figure 1-4 , 6, a solar photovoltaic sound barrier based on micro-porous ceramic foam boards, including a composite sound-absorbing panel 1 and a solar panel 2, the solar panel 2 is located on the outer side of the composite sound-absorbing panel 1 and is connected to the composite sound-absorbing panel 1 Sliding connection, the composite sound-absorbing panel 1 is sequentially provided with an aluminum-plastic plate 11 with a thickness of 2mm, a ceramic plate with micro-through holes 12 with a thickness of 23mm, and a galvanized steel plate 13 with a thickness of 2mm, and the aluminum-plastic plate 11 and the ceramic plate with micro-through holes A first cavity 14 for water storage is provided between the plates 12, a second cavity 15 is provided between the micro-through-hole ceramic plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com