Zero-carbon building cast-in-place concrete wall built-in heat preservation method and system

A concrete inner and concrete wall technology, applied in thermal insulation, construction, building components, etc., can solve the problems of not meeting the needs of zero-carbon buildings, old through-wall bolt casings are no longer applicable, and achieve simple structure, convenient construction, Good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

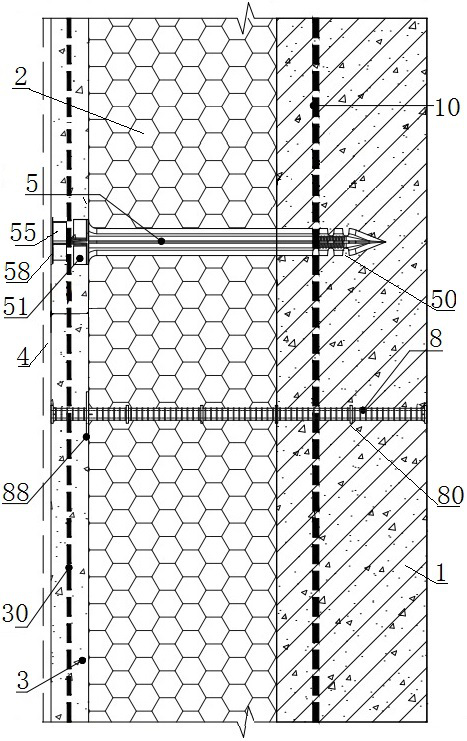

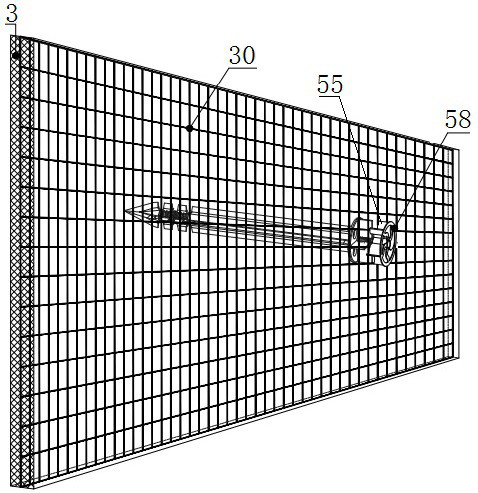

[0033] Example 1, such as Figure 1-2 And 4-16, a system for achieving a zero-carbon building in which a zero carbon building of the present invention is a hierarchical structure in which the wall from the wall is sequentially included in order, including the current pouring concrete layer 1, the insulation sheet layer 2 and concrete protective layer. The cast-in-place concrete layer 1 position is preset near the cast-in-condensed concrete of the thermal temperature plate layer 2, and the steel wire mezzanine 30 is preset from the solid concrete protective layer 3, and the cast-in-spot concrete is laminated. 30 is connected to the heat-free bridge connector for fixing the insulation plate layer 2, and the steel wire layer 10 and the insulation plate layer 2 and the steel wire mezzana of the self-compacting plate layer 3 in the current cast concrete layer 1. Retaining the wall bolt pneumatic tube 8 and the wall bolt and the two-end sealing plug, the pouring concrete layer 1 and the ...

Embodiment 2

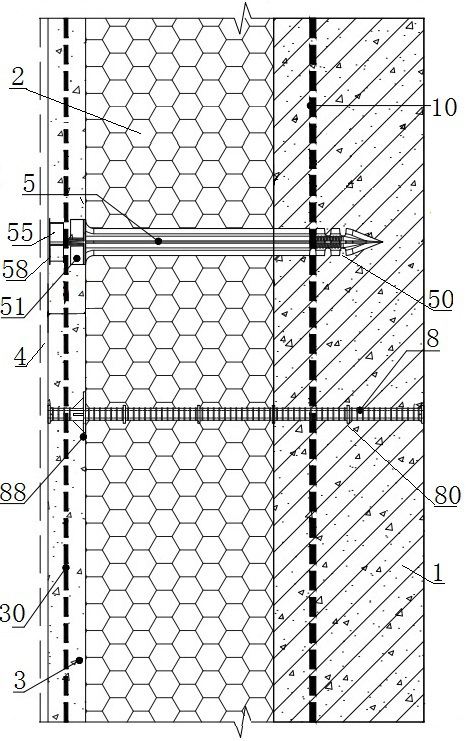

[0040] Embodiment 2, such as image 3 As shown, the difference between the insulation method and the system of the present invention and the above-described embodiment one of the above-described embodiments is provided between the limit fixation disk 88 and the outer circumference of the adjacent sleeve 88. Streduate a glibule to a uniform distributed bevel. It is also possible to provide a multi-circumferential homogeneous bevel reinforcing rib to the outer circumference of the outer circumference of the limit fixing plate and the outer circumference of the adjacent sleeve, and the restricted disk rear and adjacent sleeve The outer circumference is provided with multiple circumferential uniform distributed bevel reinforcement. Compared to the above-described embodiment, the support fixing strength of the restricted fixed disk on the insulation plate layer can be significantly enhanced.

[0041] In summary, the internal heat preservation method and system of the zero-carbon buildin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com