Compressor multi-rotor impeller and turbine multi-rotor full-contra-rotating aero-engine

A technology of aero-engine and rotor impeller, which is applied in the direction of machine/engine, engine components, engine cooling, etc. It can solve the problems of vibration noise, low conversion efficiency, unstable operation, etc., and achieve the effect of weight reduction and axial length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

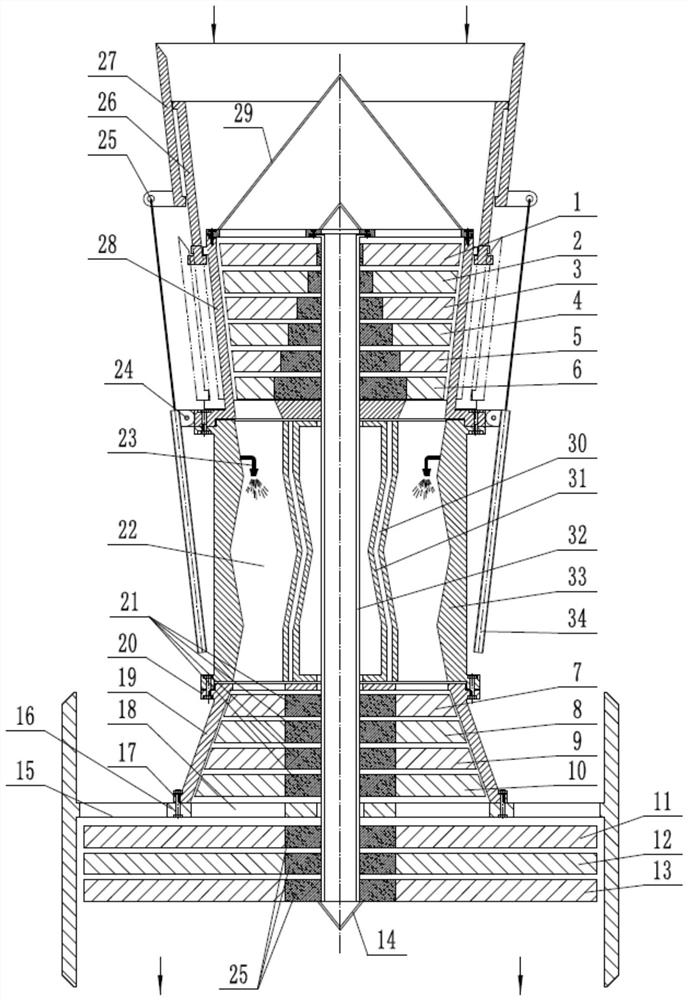

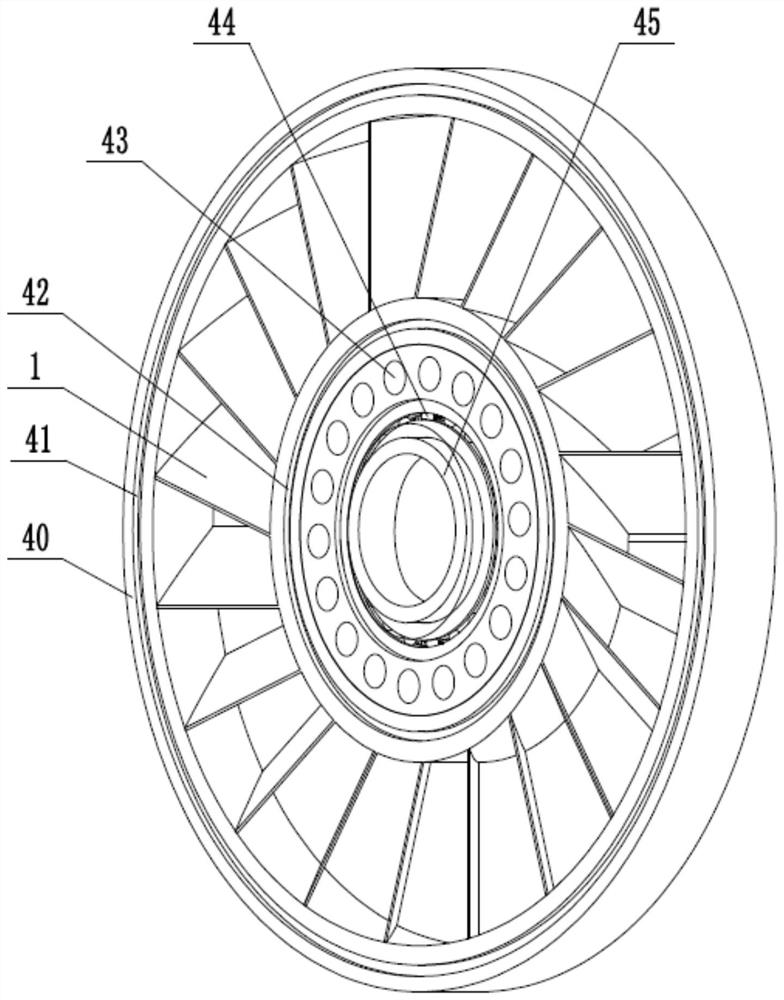

[0029] Such as figure 1 with figure 2 As shown, the present invention discloses an aero-engine in which the multi-rotor impellers of the compressor and the multi-rotor turbines of the turbine are fully counter-rotating. A central hollow mandrel 14 is longitudinally arranged in the direction of the central axis, and the central hollow mandrel 14 is exactly the longitudinal direction of the aero-engine. Skeleton, the front part of the central hollow shaft 14 is provided with an aero-engine compressor assembly 28, the middle part is provided with an aero-engine combustion chamber assembly 33, and the rear part is provided with a turbine assembly 19; the aero-engine compressor assembly 28 The rear end and the front end of the aero-engine combustion chamber assembly 33 are connected and fixed by means of a flange inner and outer spigot, and the rear end of the aero-engine combustion chamber assembly 33 is connected to the aero-engine turbine assembly 19. The front end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com