Novel high-impedance electric reactor

A high-impedance, reactor technology, used in inductors, fixed inductors, transformer/inductor cooling, etc., can solve the problems of inability to cool the reactor, slow cooling of the reactor, and burnout of the reactor, which is conducive to multiple cooling. Operation, conducive to stable work, the effect of avoiding oil waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

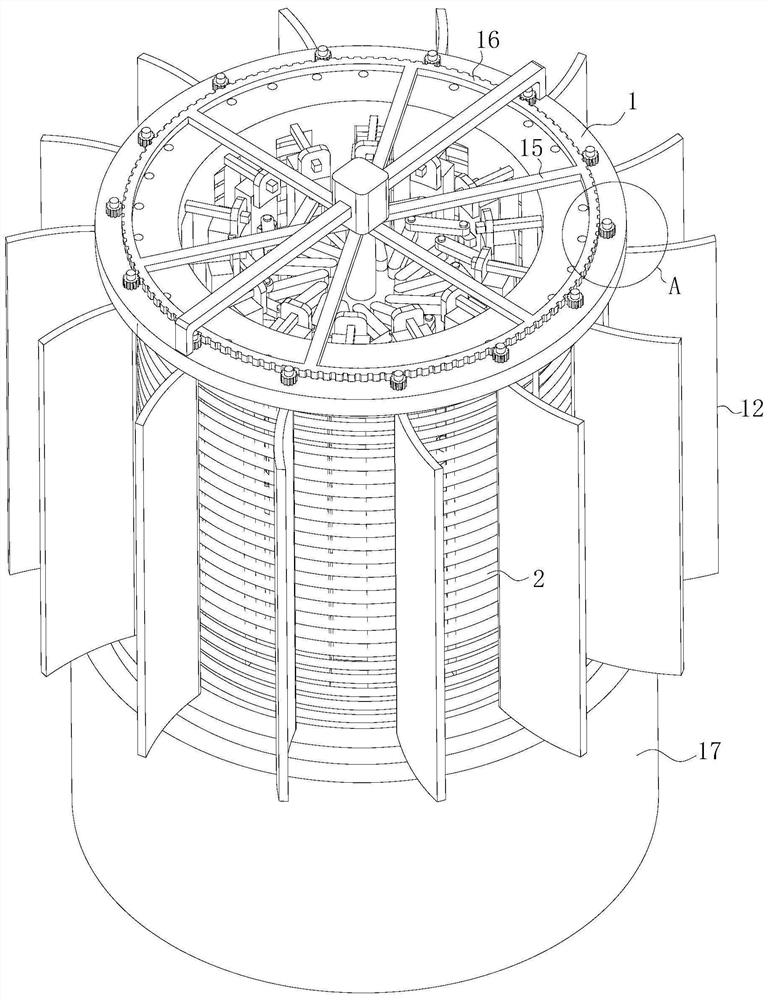

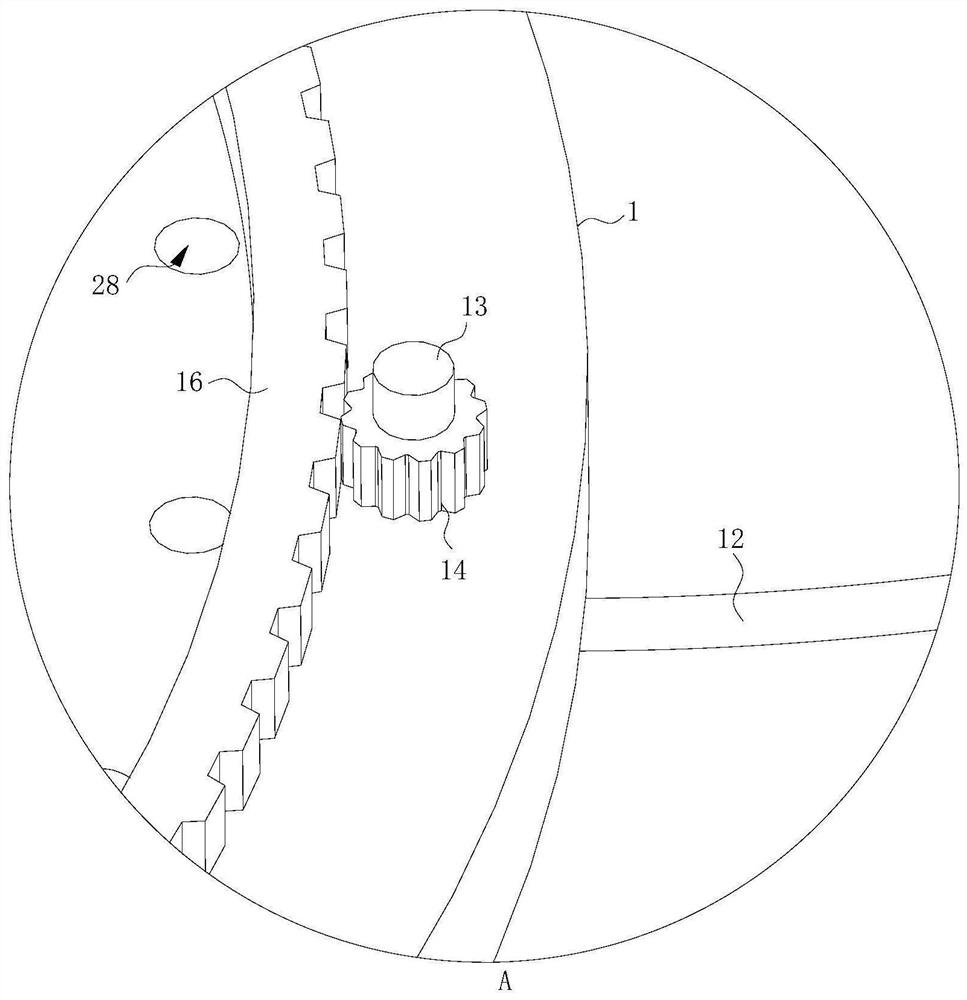

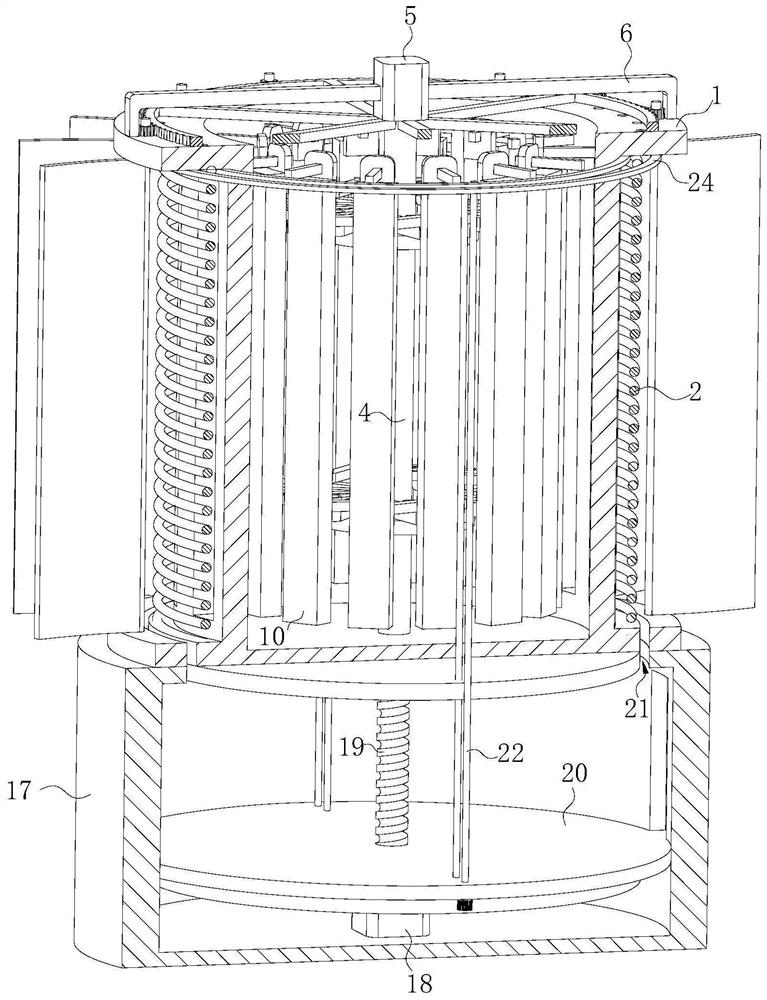

[0026] see Figure 1-8 , the present invention provides a technical solution: a new type of high-impedance reactor, including a winding cylinder 1 and a winding 2, the winding 2 is wound on the outer surface of the winding cylinder 1, and the inner side of the winding cylinder 1 is provided with a number of ventilation slots 3 in a circumferentially distributed array, The winding drum 1 is connected with a sealing mechanism for sealing the winding 2 and the ventilation groove 3. The sealing mechanism cooperates with the winding drum 1 and the sealing mechanism to seal the winding 2. The bottom of the winding drum 1 is connected with a sealing mechanism for sealing the winding 2 after the sealing mechanism An oil immersion mechanism for oil immersion cooling of the winding 2;

[0027] The sealing mechanism includes an inner sealing mechanism and an outer sealing machine, the inner sealing mechanism is used to seal the vent groove 3, the outer sealing mechanism is used to surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com