Nutrient substance cutting equipment and using method

A technology of cutting equipment and nutrients, applied in the field of mechanical processing, can solve the problems of sugar sticking to the blade, melting of brown sugar cubes, inability to cut brown sugar cubes at equal distances, etc., achieve consistent movement frequency, avoid multiple cuts and missed cuts, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

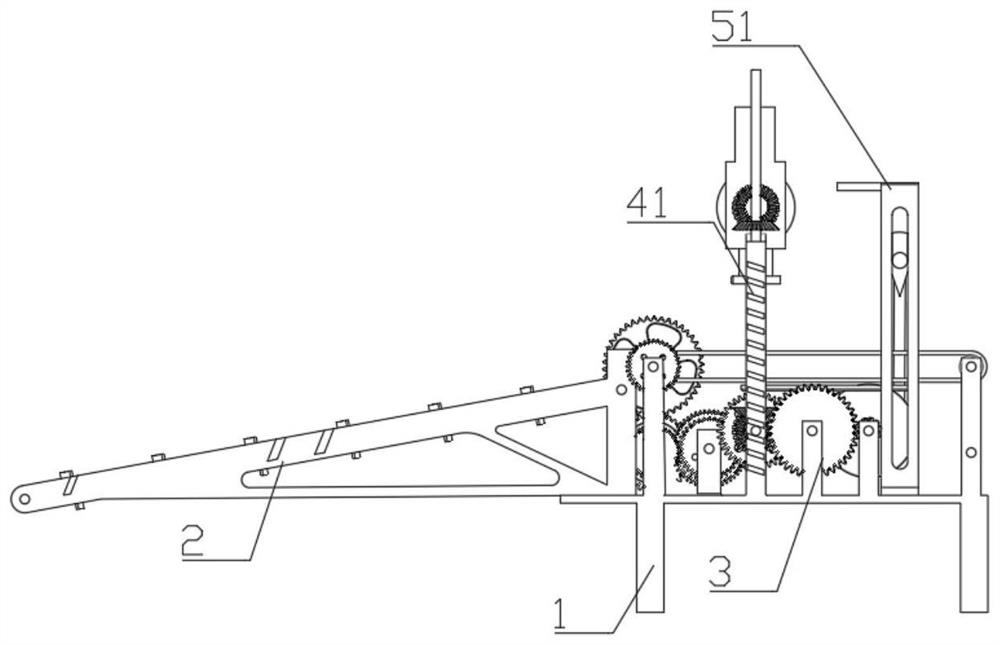

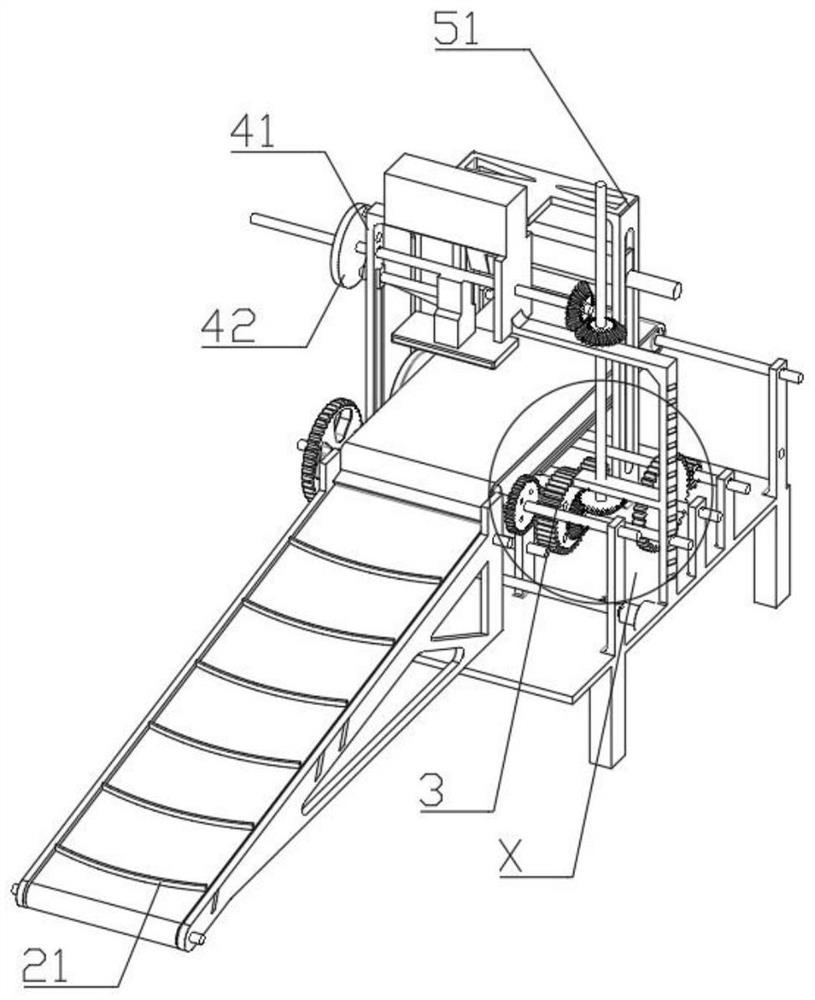

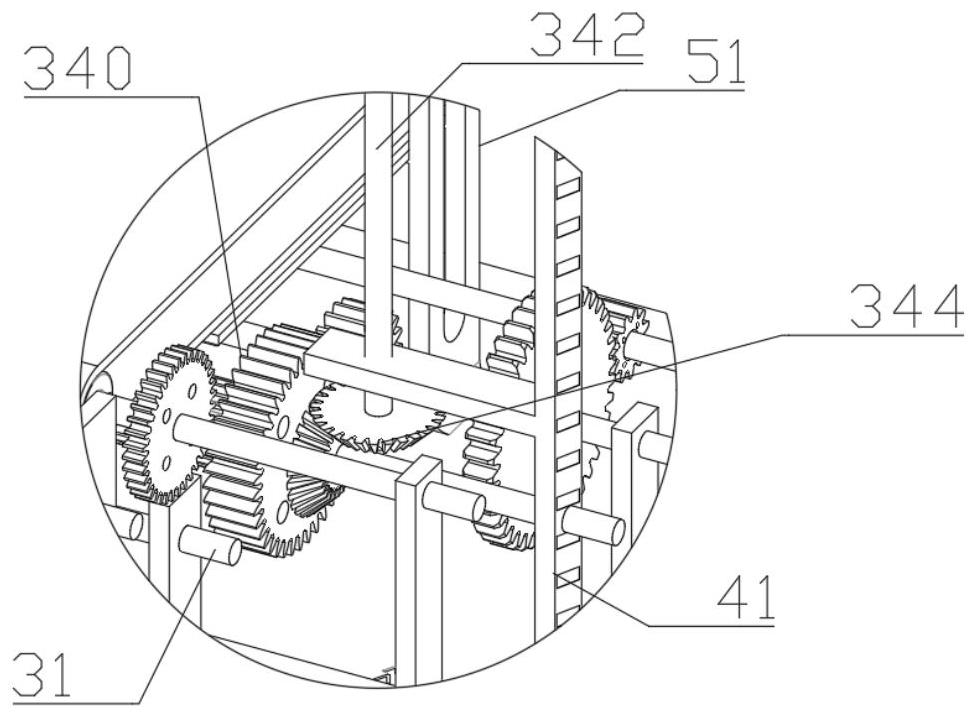

[0057] Such as Figure 1-10As shown, a kind of nutrient substance cutting equipment comprises chassis 1, conveyor belt 2, linkage mechanism 3, and pressing structure 4 and cutting mechanism 5, and conveyor belt 2 is arranged on chassis 1 top, and linkage mechanism 3 is arranged in chassis 1. Inside, the pressing structure 4 is set above the conveyor belt 2 and linked with the linkage mechanism 3. There is also a cutting structure 5 behind the pressing structure 4, and the cutting structure 5 is linked with the pressing structure 4 and the linkage mechanism 3. The cutting mechanism 5 It is located behind the pressing structure 4 and is linked with the linkage mechanism 3. The device is fixed by the chassis 1, and then the linkage mechanism 3 drives the conveyor belt 2 to rotate and transport the raw materials connected in blocks, and then the raw materials are connected by the pressing structure 4. Compression, the cutting mechanism 5 presses down to cut the compressed raw mate...

Embodiment 2

[0059] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a kind of nutrient substance cutting equipment comprises chassis 1, conveyor belt 2, linkage mechanism 3, and pressing structure 4 and cutting mechanism 5, and conveyor belt 2 is arranged on chassis 1 top, and linkage mechanism 3 is arranged in chassis 1. Inside, the pressing structure 4 is set above the conveyor belt 2 and linked with the linkage mechanism 3. There is also a cutting structure 5 behind the pressing structure 4, and the cutting structure 5 is linked with the pressing structure 4 and the linkage mechanism 3. The cutting mechanism 5 It is located behind the pressing structure 4 and is linked with the linkage mechanism 3. The device is fixed by the chassis 1, and then the linkage mechanism 3 drives the conveyor belt 2 to rotate and transport the raw materials connected in blocks, and then the raw materials are connected by the pressing structure 4. Compressio...

Embodiment 3

[0064] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a kind of nutrient substance cutting equipment comprises chassis 1, conveyor belt 2, linkage mechanism 3, and pressing structure 4 and cutting mechanism 5, and conveyor belt 2 is arranged on chassis 1 top, and linkage mechanism 3 is arranged in chassis 1. Inside, the pressing structure 4 is set above the conveyor belt 2 and linked with the linkage mechanism 3. There is also a cutting structure 5 behind the pressing structure 4, and the cutting structure 5 is linked with the pressing structure 4 and the linkage mechanism 3. The cutting mechanism 5 It is located behind the pressing structure 4 and is linked with the linkage mechanism 3. The device is fixed by the chassis 1, and then the linkage mechanism 3 drives the conveyor belt 2 to rotate and transport the raw materials connected in blocks, and then the raw materials are connected by the pressing structure 4. Compressio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap