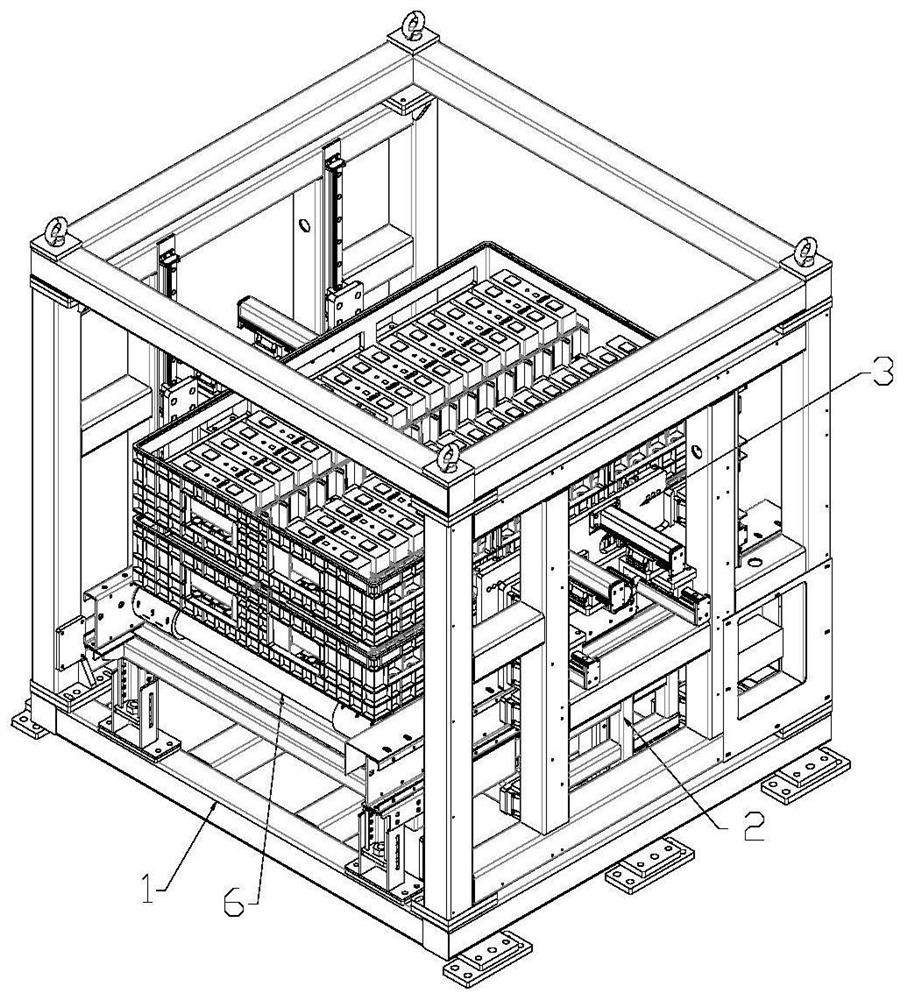

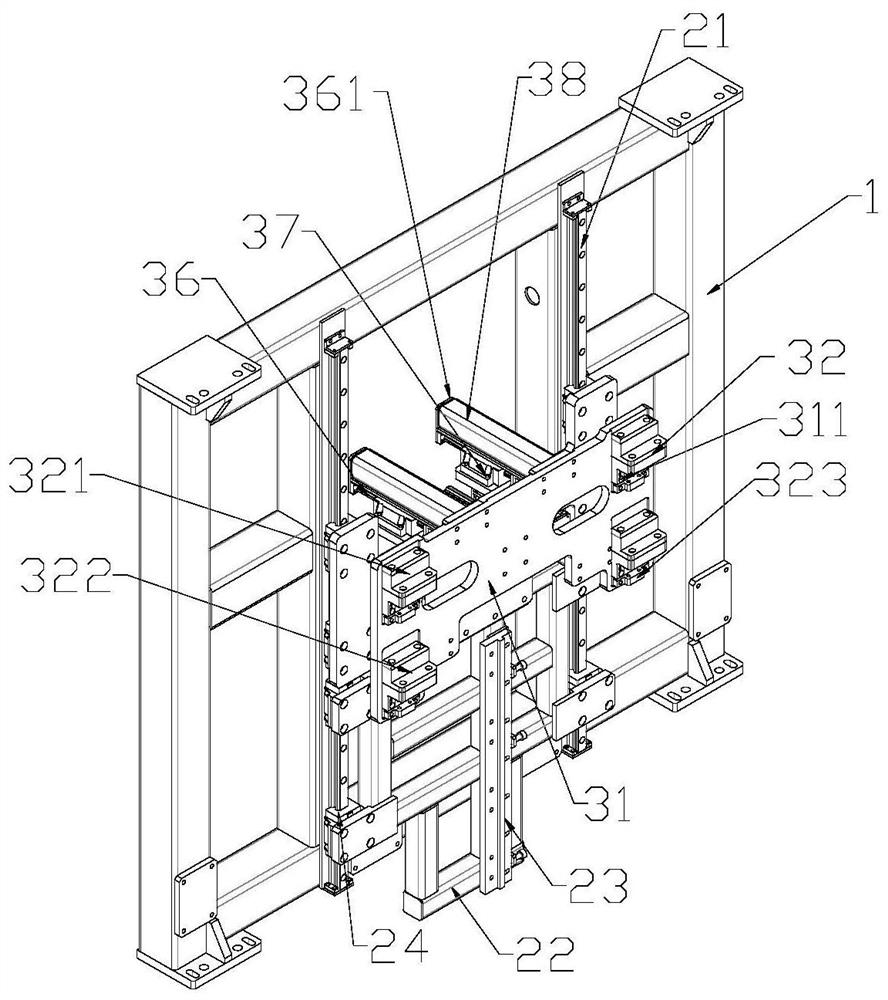

New energy battery tray stacking device

A new energy and battery technology, applied in the field of stacking machines, can solve the problem of easy damage of battery trays, and achieve the effects of improved stacking efficiency, high stacking accuracy, and small position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

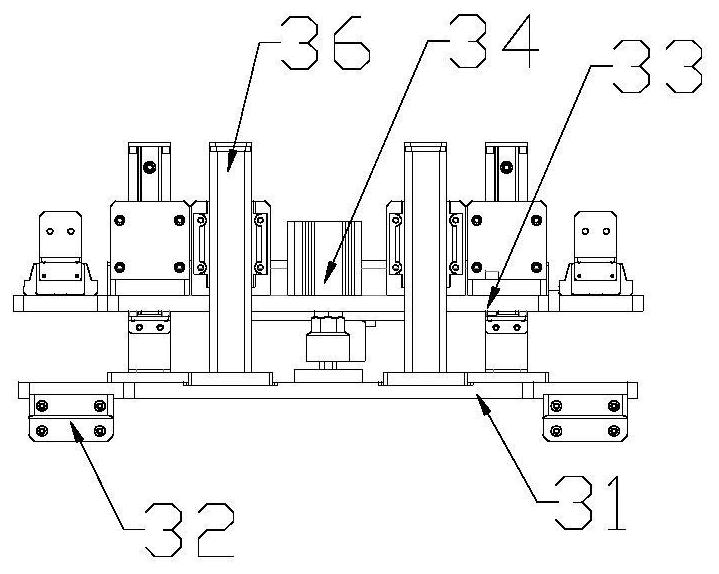

[0056] In this embodiment, other components are the same as in Embodiment 1, and Embodiment 2 only improves the fine-tuning mechanism, please refer to Figure 4 , the fine-tuning mechanism includes a screw rod 312, the side of the clamping plate 31 is provided with a groove, the screw rod 312 is fixed on the inner surface of the groove, the screw rod 312 passes through the supporting plate 32 and the aperture of the supporting plate 32 is greater than the diameter of the screw rod 312, the lower part of the supporting plate 32 The end surface is attached with a nut 313 that engages with the screw rod 312. By adjusting the position of the nut 313 on the screw rod 312, the position of the supporting plate 32 is controlled, so that the supporting plate 32 can compensate for the installation error of the lifting mechanism, thereby stably lifting Lift the battery tray to avoid the problem of uneven force on the battery tray caused by lifting tilt and easy damage to the lifting place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com