Porous conductive ceramic material for heating and preparation method thereof

A ceramic material, porous conductive technology, applied in tobacco and other directions, can solve the problems of restricting the expansion of ceramic heating elements and complex preparation process, and achieve the effects of diverse and controllable heating surfaces, large heating area, and reducing the complexity of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

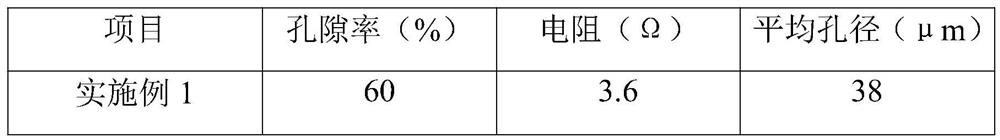

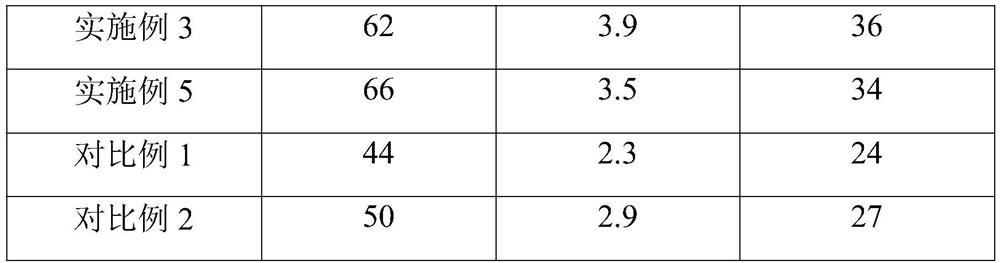

Examples

Embodiment 1

[0030] A porous conductive ceramic material for heating, comprising the following raw materials in parts by weight: 5 parts of ceramic powder, 1 part of binder, 0.5 part of pore-forming agent, 20 parts of conductive bone powder, 5 parts of nano-silica powder, 10 parts of organic carrier and auxiliary Conductive agent 1 part.

[0031] Each part of the pore-forming agent includes the following raw materials in parts by weight: 8 parts of polymethyl methacrylate microspheres, 6 parts of methyl methacrylate, 1 part of alumina micropowder, 1 part of silicon micropowder, 1 part of TiBCN powder, carbonized 1 part silicon powder, SnCl 4 ·5H 2 1 part of O solution and 1 part of silica gel solution.

[0032] The pore-forming aid is prepared by the following method:

[0033] S1. According to parts by weight, the polymethyl methacrylate microspheres and methyl methacrylate are mixed and stirred first to obtain mixture A, and the silica gel solution and SnCl are mixed by a peristaltic p...

Embodiment 2

[0047] A porous conductive ceramic material for heating, comprising the following raw materials in parts by weight: 6 parts of ceramic powder, 2 parts of binder, 1 part of pore-forming agent, 23 parts of conductive bone powder, 6 parts of nano-silica powder, 13 parts of organic carrier and auxiliary Conductive agent 2 parts.

[0048] Each part of the pore-forming agent includes the following raw materials in parts by weight: 10 parts of polymethyl methacrylate microspheres, 8 parts of methyl methacrylate, 2 parts of alumina micropowder, 2 parts of silicon micropowder, 2 parts of TiBCN powder, carbonized 2 parts of silicon powder, SnCl 4 ·5H 2 2 parts of O solution and 1.5 parts of silica gel solution.

[0049] The pore-forming aid is prepared by the following method:

[0050] S1. According to parts by weight, first mix and stir polymethyl methacrylate microspheres and methyl methacrylate to obtain mixture A, and mix silica gel solution and SnCl with a peristaltic pump at a ...

Embodiment 3

[0064] A porous conductive ceramic material for heating, comprising the following raw materials in parts by weight: 7 parts of ceramic powder, 3 parts of binder, 1.5 parts of pore-forming agent, 25 parts of conductive bone powder, 7 parts of nano-silica powder, 15 parts of organic carrier and auxiliary Conductive agent 3 parts.

[0065] Each part of the pore-forming agent includes the following raw materials in parts by weight: 12 parts of polymethyl methacrylate microspheres, 10 parts of methyl methacrylate, 3 parts of alumina micropowder, 3 parts of silicon micropowder, 3 parts of TiBCN powder, carbonized 3 parts of silicon powder, SnCl 4 ·5H 2 3 parts of O solution and 2 parts of silica gel solution.

[0066] The pore-forming aid is prepared by the following method:

[0067] S1. According to parts by weight, first mix and stir polymethyl methacrylate microspheres and methyl methacrylate to obtain mixture A, and mix silica gel solution and SnCl with a peristaltic pump at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com