Double-steel-plate concrete composite shear wall for locking piece assembly stiffening

A technology of combining shear walls and double steel plates, applied in the direction of walls, building components, buildings, etc., can solve the problems of large welding volume, complex construction, large carbon emissions, etc., to improve labor efficiency and productivity, and reduce the amount of welding works. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

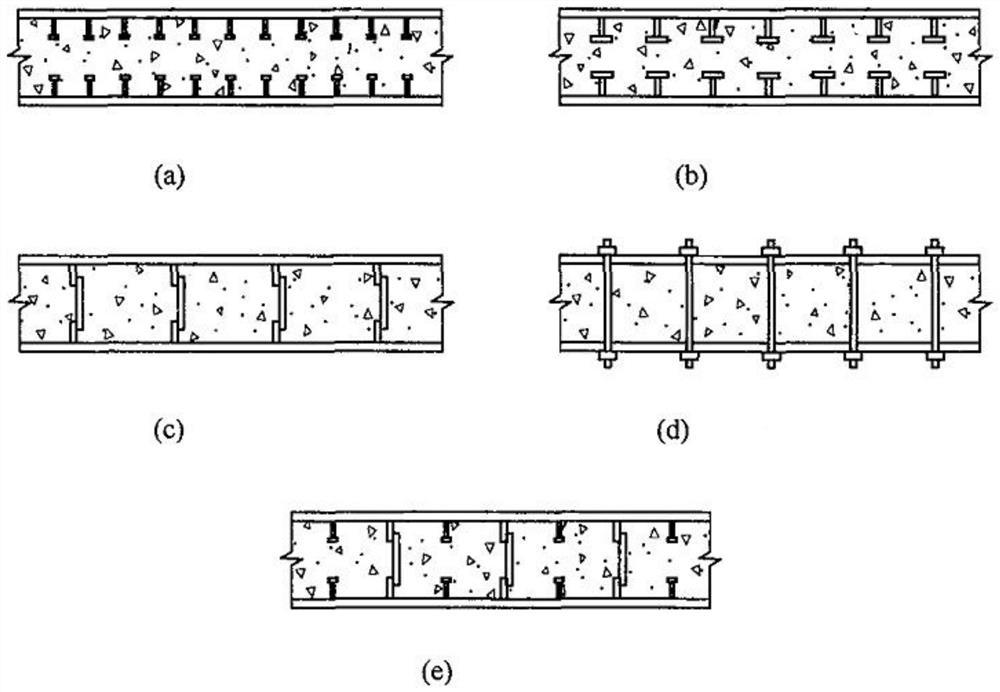

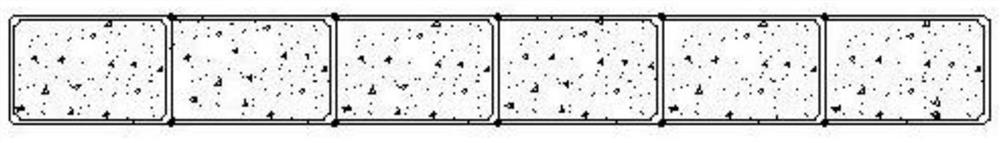

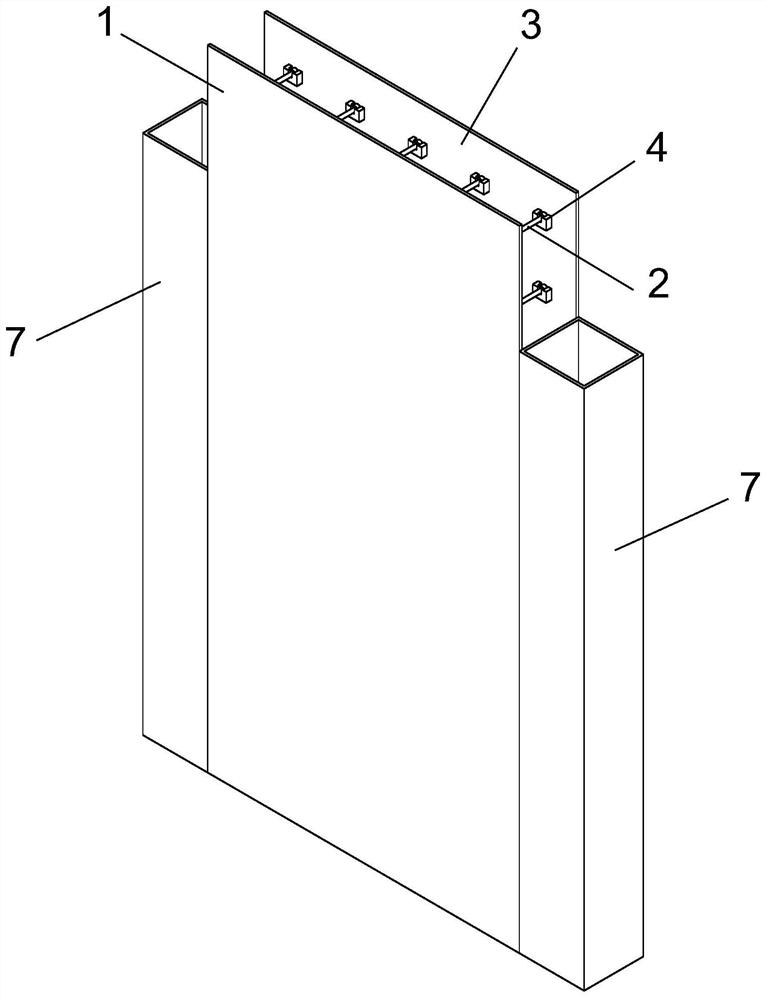

[0035] Embodiment 1 (see Figure 3-8 ):

[0036] The transverse connector 2 is a stud, the head of the stud faces backwards, and its tail is fixedly connected to the front plate member 1; the locking member 4 is provided with a T-shape that matches the head of the stud. Slot 5.

[0037] The tail of the peg is welded and fixed on the front plate member 1 .

[0038] The notch of the T-shaped slot 5 faces upward.

Embodiment 2

[0039] Embodiment 2 (see Figure 9-14 ):

[0040] The transverse connector 2 is an L-shaped plate, the rear end of the L-shaped plate is bent downward; the front end of the L-shaped plate is welded and fixed on the front plate member 1 .

[0041] The locking member 4 is provided with a vertical groove 8 matching the bent portion of the rear end of the L-shaped plate.

[0042] The prefabricated component production process and construction of the present invention are roughly divided into the following multiple steps:

[0043] The first step is to deepen the drawings, and carry out the factory prefabricated split design according to the designed shear wall plane drawings, and split them into prefabricated shear wall body parts and edge parts produced in the factory.

[0044]The second step is factory processing. 1. The rectangular steel pipe column at the edge can be directly purchased or processed by steel plate blanking in the factory; 2. The front and rear plate components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com