Middle feeding slag separating and screening structure and operation method thereof

An operation method and slag separation technology, which are applied in chemical instruments and methods, sieves, and the separation of solids from solids by air flow, etc., can solve the problems of low screening efficiency, single screening method, blockage of media boxes, etc. The effect of screening speed, improving screening quality, and preventing waterway blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

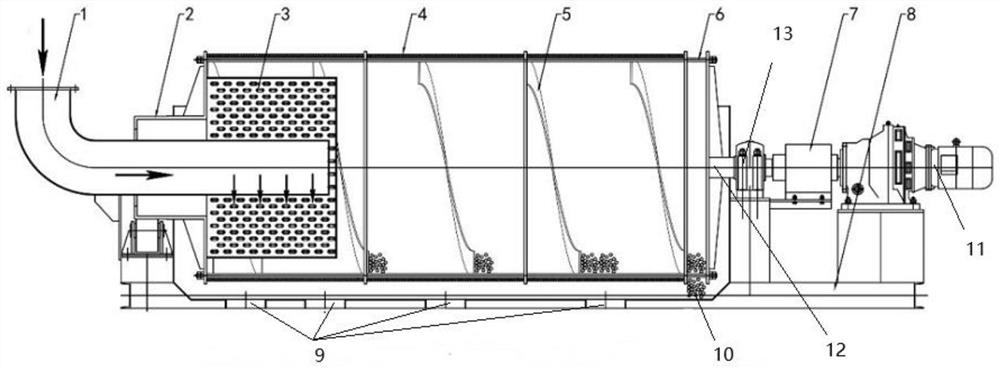

[0020] Example: see figure 1 , the present invention provides a technical solution: a middle feeding slag screening structure, including feeding pipe 1, rolling bearing 2, cloth screen cylinder 3, screen mesh 4, slag discharge screw auger 5, screen body skeleton 6, deceleration Box 7, frame 8, liquid outlet 9, slag outlet 10, drive motor 11, connecting shaft 12 and coupling 13, one end top of frame 8 is connected with feed pipe 1, and feed pipe 1 is installed with Rolling bearing 2, a sieve frame 6 is installed on the rolling bearing 2, a screen 4 is installed on the sieve frame 6, a slag discharge screw auger 5 is arranged inside the sieve body frame 6, and a cloth screen cylinder is connected to one end of the feed pipe 1 3. One end of the sieve frame 6 is connected with a connecting shaft 12, and one end of the connecting shaft 12 is connected with the reduction box 7, and the reduction box 7 is connected with the drive motor 11. The sieve body frame 6 is arranged on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com