Four-head servo liquid filling machine with automatic material supplementing structure

A technology of filling machine and mobile structure, which is applied in the direction of liquid materials, packaging, transportation and packaging, etc. It can solve the problems of inability to flow, mechanical work that is prone to errors, inconvenient opening and closing, etc., so as to prolong the service life and avoid errors , The effect of convenient material guide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

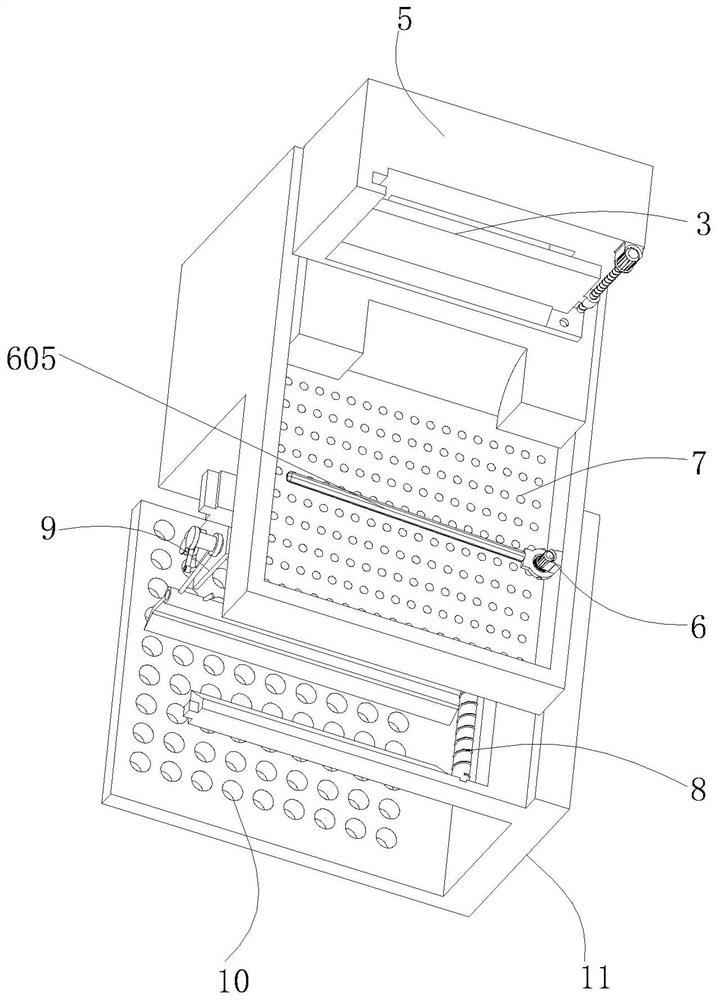

[0039] Embodiment 1: The automatic feeding of the filling machine is facilitated by the cooperation of the moving structure 8 and the discharge structure 9, and the traditional manual feeding is replaced by the motor drive mode. The cost of the motor drive method is lower than that of manual feeding, and through The motor replaces manual work to complete this type of mechanical work, which can avoid mistakes and reduce the frequency of production accidents;

Embodiment 2

[0040] Embodiment 2: Double-layer filtration is set through the first sieve plate 7 and the second sieve plate 10. The liquid filling machine is a filling machine used to fill liquid objects, and liquid foods are generally mixed with some solid objects. , leading to a certain amount of residue in the liquid filling machine. Food without filtered residue will affect the taste and the storage time will be shortened accordingly, because the bacteria inside the solid residue are not easy to remove, which will cause the liquid food to be perishable;

Embodiment 3

[0041]Embodiment 3: It is convenient to guide the material through the material guide structure 6, the texture of the liquid food is different, and the flow speed of the thicker liquid food is relatively slow when passing through the sieve plate, and when the flow speed of the material is too slow, the material will be blocked in the sieve There is no flow on the board.

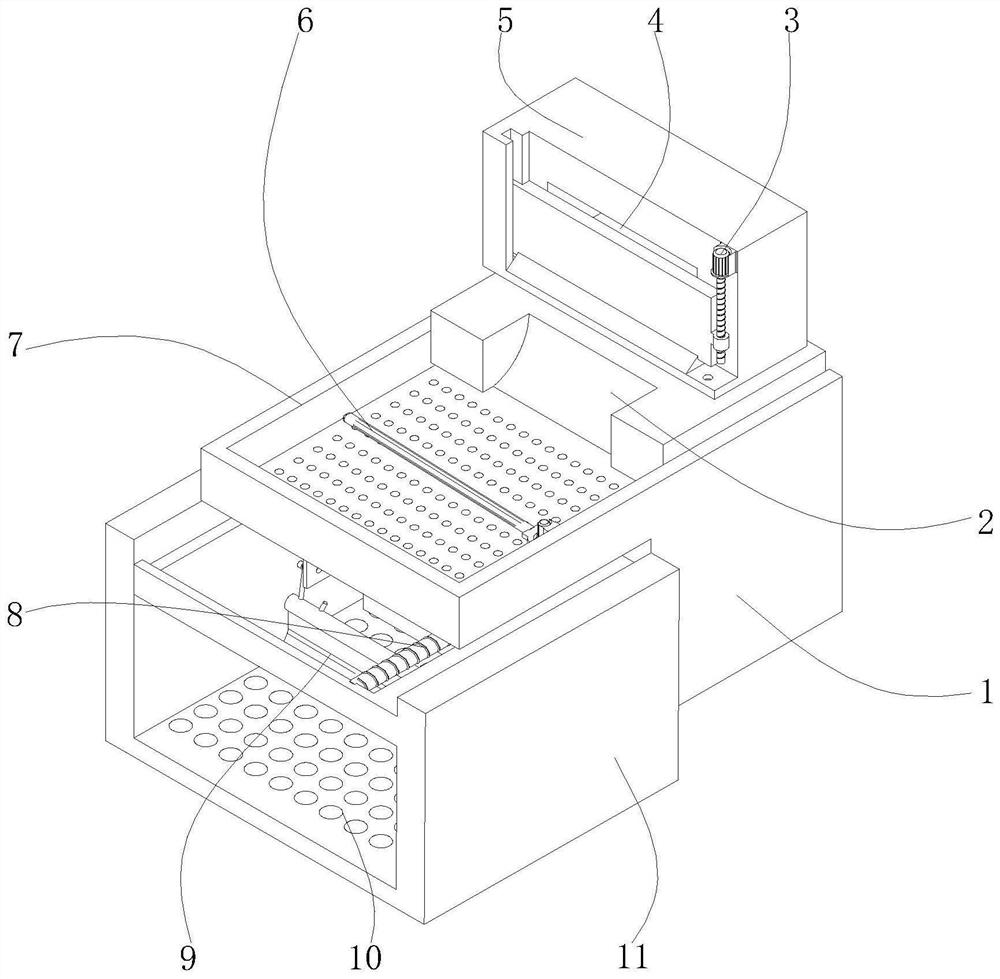

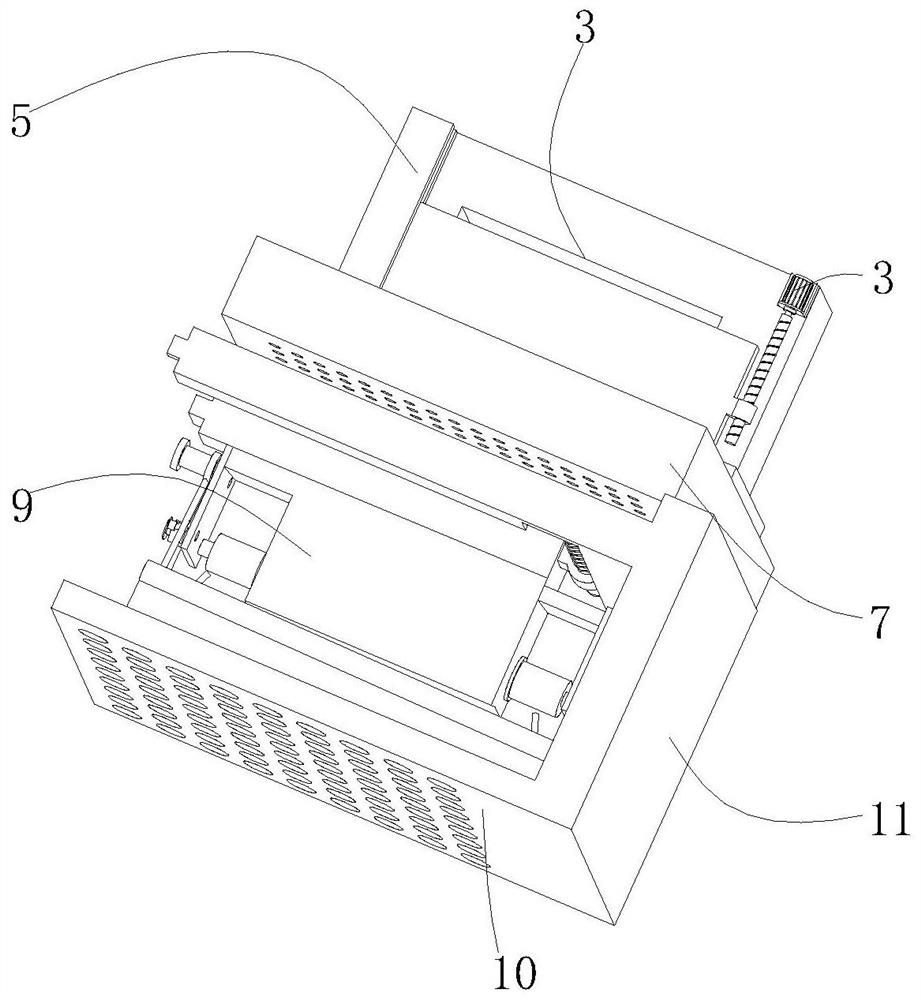

[0042] Such as Figure 1-Figure 4 As shown, a four-head servo liquid filling machine with an automatic feeding structure, a four-head servo liquid filling machine with an automatic feeding structure, including:

[0043] The first fixed frame 1, one side of the top of the first fixed frame 1 is fixedly connected with the installation ramp 2, and the side of the top of the first fixed frame 1 away from the installation ramp 2 is fixedly connected with the first sieve plate 7, and the ramp is installed The top of 2 is fixedly connected with a second fixed frame 5, and the two sides of the second fixed frame 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com