Water-based aluminum oxynitride transparent ceramic slurry for 3D printing and preparation method of water-based aluminum oxynitride transparent ceramic slurry

A technology of aluminum oxynitride and transparent ceramics, applied in the direction of additive processing, etc., can solve the problems of affecting the solid content and viscosity of ceramic slurry, the deviation of component ratio from the expected design, and reducing the printability of aluminum oxynitride transparent ceramic slurry. , to achieve the effect of sufficient supply in the domestic market, moderate viscosity, and excellent optical/mechanical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

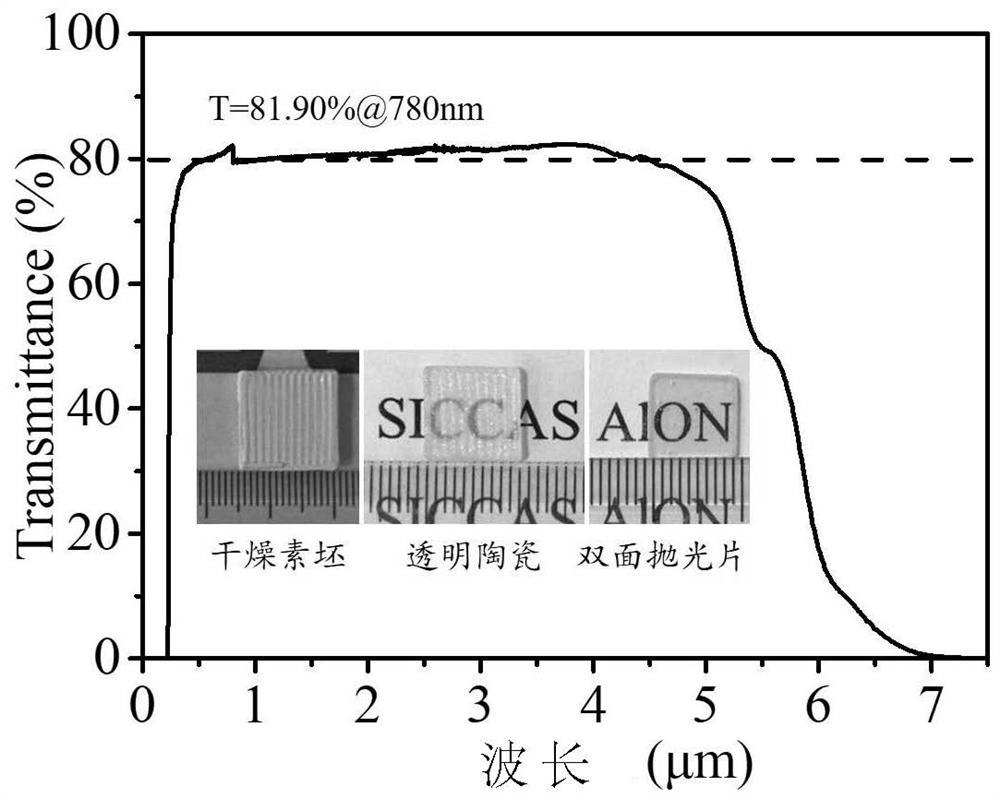

[0065] Embodiment 1: Mainly including preparation of hydration-resistant aluminum oxynitride ceramic powder, preparation of water-based aluminum oxynitride ceramic slurry, 3D printing, high-temperature sintering and other steps:

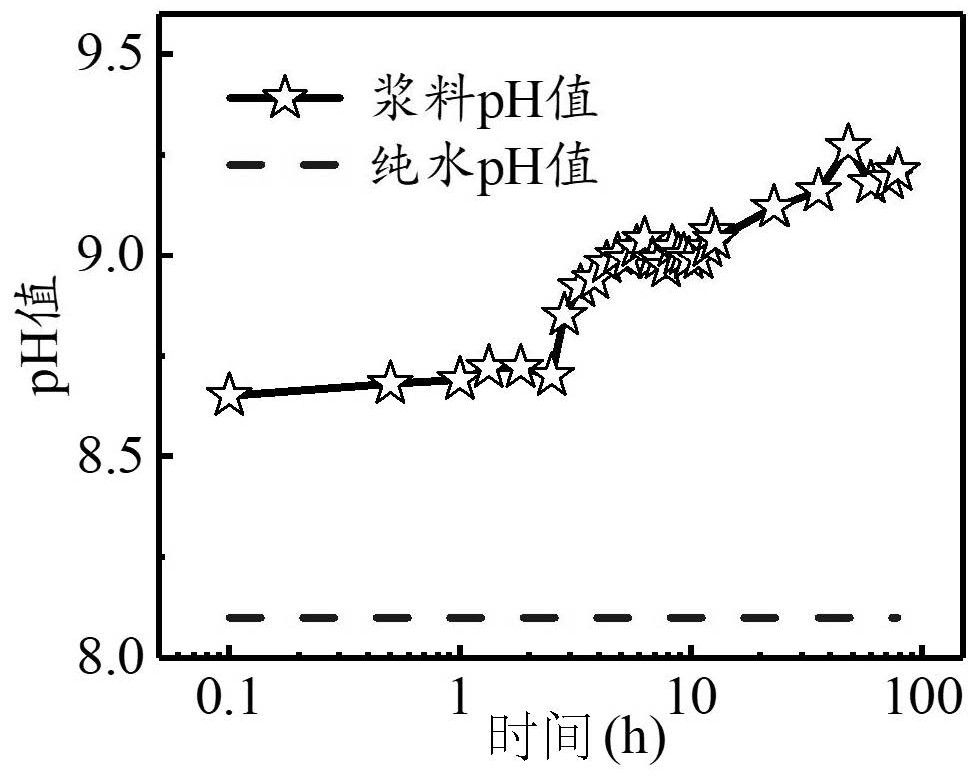

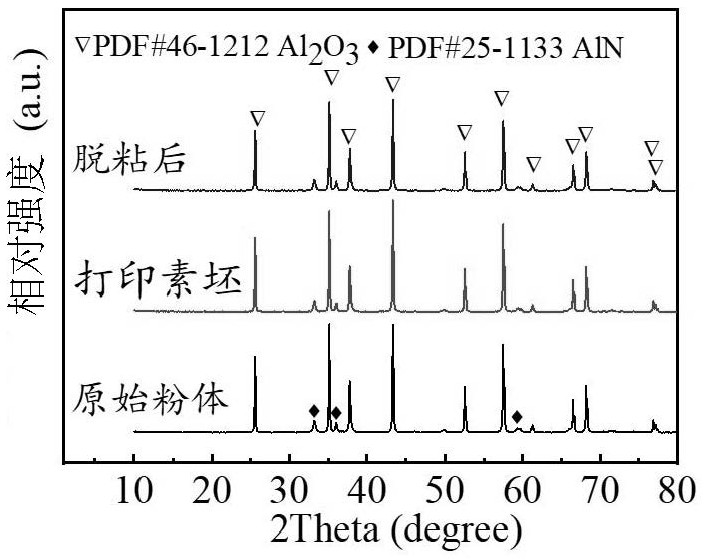

[0066] (1) Preparation of hydration-resistant aluminum oxynitride ceramic powder: according to Table 1, weigh Al respectively according to the mass ratio of 84.70:15.30 2 o 3 Powder (purity > 99.90%, average particle size 0.65 μm) and AlN powder (purity > 99.90%, average particle size 0.85 μm). Add 0.40wt% MgAl 2 o 4 (purity>99.99%) and 0.10wt% Y 2 o 3 (Purity > 99.99%) As a sintering aid, add 0.12wt% H 3 BO 3 (purity > 99.99%) as a hydration inhibitor, with absolute ethanol as the dispersion medium, using a high-purity alumina ball mill tank, high-purity alumina balls as the ball milling medium to carry out ball milling and mixing of the mixed powder, at 270 rpm Ball milling and mixing under the same conditions for 36 hours, the ball milled s...

Embodiment 2

[0076] The preparation process of the aluminum oxynitride ceramic slurry in Example 2 is as in Example 1, with the difference that: the amount of water added is controlled so that the solid content of the aluminum oxynitride ceramic slurry is 81 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com