Crystallization refining method of tetrabutylammonium bromide

A technology of tetrabutylammonium bromide and refining method, which is applied in the direction of amino compound purification/separation, organic chemistry, etc., can solve the problems of low production efficiency and long time consumption, and achieve low impurity content, shortened time and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

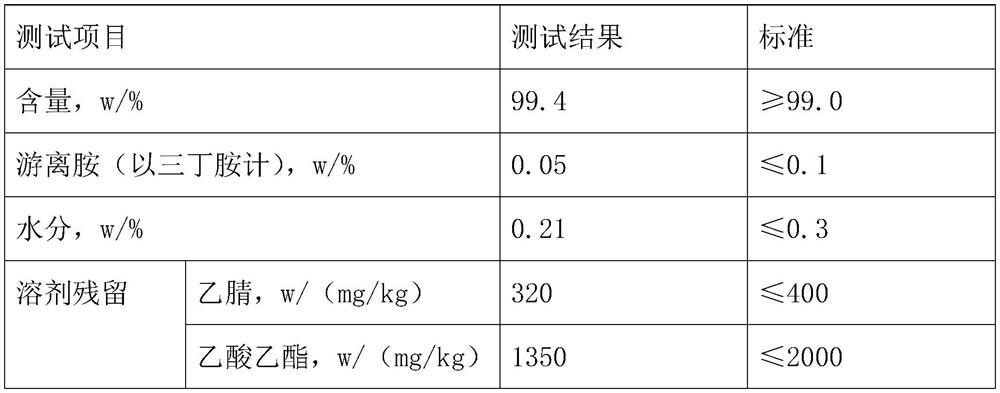

Examples

Embodiment 1

[0021] A kind of crystallization refining method of tetrabutylammonium bromide, comprises the following steps:

[0022] S1. Add ethyl acetate into the reaction kettle, preheat to 33°C, then add molten crude tetrabutylammonium bromide under the condition of stirring at 100rpm, and ultrasonically treat it for 4min at the frequency of 40kHZ and the power of 150W to obtain Crystal stock solution, wherein the mass ratio of crude tetrabutylammonium bromide to ethyl acetate is 0.9:1;

[0023] S2. Cool the crystallization stock solution to 9°C at a cooling rate of 12°C / h, crystallize under the stirring condition of 100rpm for 2.5h, and then raise the temperature to 13°C at a heating rate of 4°C / h. Ultrasonic treatment for 8 minutes under the condition;

[0024] S3. Cool down to 5°C at a cooling rate of 4°C / h, crystallize under 100rpm stirring conditions for 4.5h, then raise the temperature to 9°C at a heating rate of 4°C / h, and ultrasonicate at a frequency of 40kHZ and a power of 550...

Embodiment 2

[0031] A kind of crystallization refining method of tetrabutylammonium bromide, comprises the following steps:

[0032] S1. Add ethyl acetate into the reaction kettle, preheat to 30°C, then add molten crude tetrabutylammonium bromide under the condition of stirring at 50rpm, and ultrasonically treat it for 3min under the condition of frequency 30kHZ and power 100W, to obtain Crystal stock solution, wherein the mass ratio of crude tetrabutylammonium bromide to ethyl acetate is 0.8:1;

[0033] S2. Cool the crystallization stock solution to 10°C at a cooling rate of 10°C / h, crystallize under the stirring condition of 50rpm for 2h, and then raise the temperature to 12°C at a heating rate of 3°C / h, under the conditions of frequency 30kHZ and power 100W Ultrasonic treatment for 5 minutes;

[0034] S3. Cool down to 5°C at a cooling rate of 3°C / h, crystallize under stirring conditions of 50rpm for 4h, then raise the temperature to 8°C at a heating rate of 3°C / h, and perform ultrasoni...

Embodiment 3

[0039] A kind of crystallization refining method of tetrabutylammonium bromide, comprises the following steps:

[0040] S1. Add ethyl acetate into the reaction kettle, preheat to 35°C, then add molten crude tetrabutylammonium bromide under the condition of stirring at 150rpm, and ultrasonically treat it for 5min under the condition of frequency 40kHZ and power 200W, to obtain Crystal stock solution, wherein the mass ratio of crude tetrabutylammonium bromide to ethyl acetate is 1:1;

[0041] S2. Cool the crystallization stock solution to 8°C at a cooling rate of 15°C / h, crystallize at a stirring condition of 150rpm for 3h, then raise the temperature to 15°C at a heating rate of 5°C / h, under the conditions of a frequency of 40kHZ and a power of 200W Ultrasonic treatment for 10 minutes;

[0042] S3. Cool down to 6°C at a cooling rate of 5°C / h, crystallize under stirring conditions of 150rpm for 5h, then raise the temperature to 10°C at a heating rate of 5°C / h, and perform ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com