Efficient decoloring method of amino acid fermentation liquor

A fermentation broth and amino acid technology is applied in the field of decolorization of amino acid fermentation broth, which can solve the problems of inability to remove precursor substances, affect product quality, dark color of fermentation broth, etc., and achieve the effects of improving overall decolorization efficiency, economical convenience, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation method of seed culture solution:

[0042] (1) Brevibacterium flavum (preservation number: CCTCC NO: M 2019496) preserved in a 1 mL glycerol tube was inoculated into 50 mL of LB medium, and cultured on a shaker at 37°C and 210 r / min until pH 6.2-6.5, OD The value is 3-4, and the LB seed solution is obtained;

[0043] (2) Take 5 mL of LB seed liquid, inoculate it into 200 mL of synthetic medium, and culture it on a shaker at 37°C and 210 r / min until pH 6.4-6.6 and OD value is 3-4 to obtain Seed culture fluid.

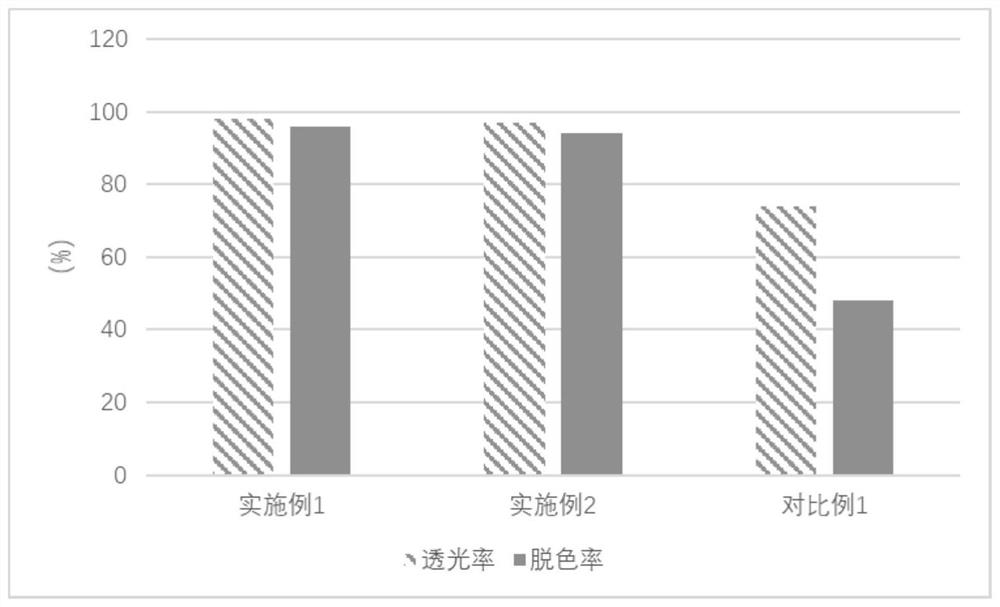

Embodiment 1

[0045] (1) Inoculate the seed culture solution into 10L fermentation medium according to the inoculum size of 2%, ferment and cultivate it at 35°C and pH6-7 until the OD value of the solution is 3, add 0.15g of sterilized sodium erythorbate, and continue Cultivate, stop fermentation when detecting that the glucose content in the fermented liquid is 1.3g / L, obtain 10L L-valine fermented liquid;

[0046] (2) Sterilizing the L-valine fermentation liquid at 0.23 MPa and 53° C. for 25 minutes to prepare the L-valine fermentation sterilization liquid;

[0047] (3) The L-valine fermented and sterilized solution was filtered through ceramic membrane and nanofiltration membrane in turn to obtain 13L of filtrated liquid; wherein the pressure of the ceramic membrane into the membrane was 0.3MPa, and the flux was 6L / min / m 2 , the material temperature is 35°C; the molecular weight cut-off of the nanofiltration membrane is 2000D, the membrane inlet pressure is 0.6MPa, and the flux is 0.6L / m...

Embodiment 2

[0050] (1) Inoculate the seed culture solution into 10L fermentation medium according to the inoculum size of 2%, ferment and cultivate at 35°C and pH6-7 until the OD value of the solution is 30, add 0.15g of sterilized isoascorbic acid, and continue Cultivate, stop fermentation when detecting that the glucose content in the fermented liquid is 1.3g / L, obtain 10L L-valine fermented liquid;

[0051] (2) Sterilizing the L-valine fermentation broth at 0.23MPa and 53°C for 25 minutes to prepare the L-valine fermentation sterilization fluid;

[0052] (3) The L-valine fermented and sterilized solution is filtered with ceramic membrane and nanofiltration membrane in turn to obtain 13L of filtrated liquid; wherein the membrane inlet pressure of the ceramic membrane is 0.3MPa, and the flux is 6L / min / m 2 , the material temperature is 35°C; the molecular weight cut-off of the nanofiltration membrane is 2000D, the membrane inlet pressure is 0.6MPa, and the flux is 0.6L / min / m2 , the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com