Unit structure of assembly type house, production method and assembly method

An assembly method and unit structure technology, which is applied in residential construction, building structure, and processing of building materials, etc., can solve the problems of multi-work construction personnel requiring high skills, inability to mass-produce components, and increasing working hours. Achieve the effect of easy product production control, reduce labor costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

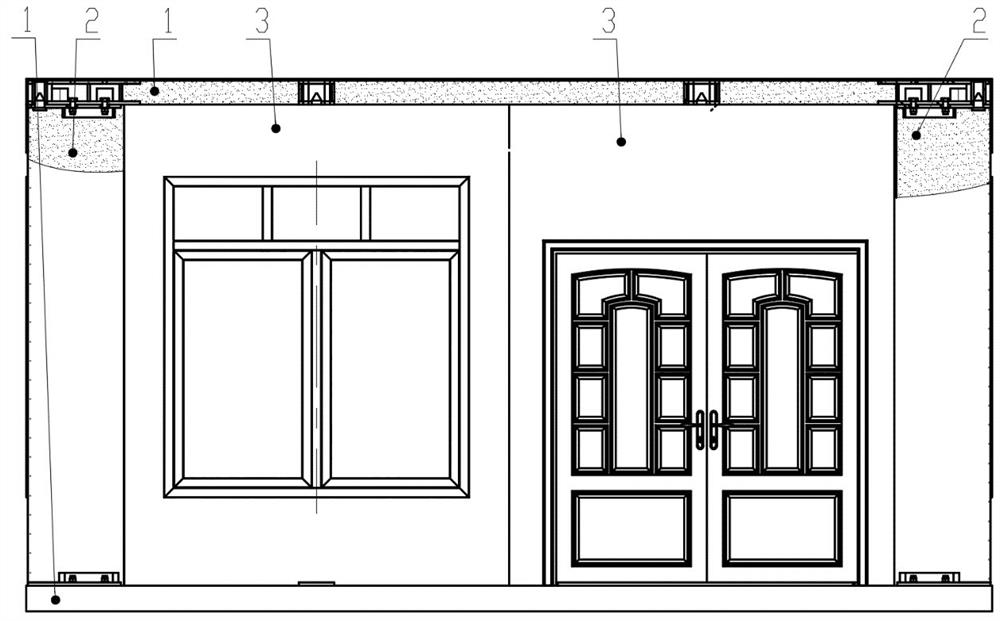

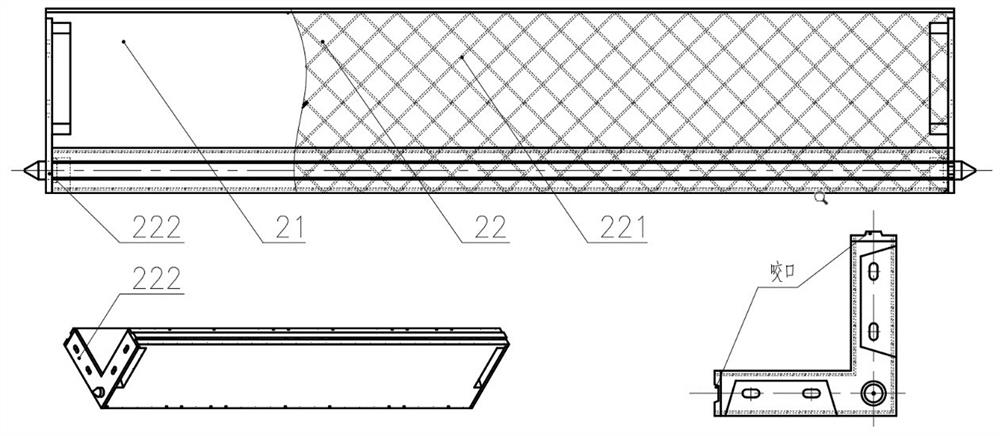

[0036] Such as figure 1 As shown, the basic unit of this embodiment is composed of a bottom plate component (1) a corner component (2) and a wall panel component (3);

[0037]The embodiment consists of two bottom plate parts (1) which are respectively the top and the bottom of the house unit. A window wall and a door opening wall in front. There are 1 solid wall on both sides. On the back are 2 window opening walls. The window opening wall and door opening wall have the same dimensions, the difference lies in the opening size and opening position, and they are produced in the factory using the same set of fixtures and molds. The house has four corner parts (2) respectively located at the four corners of the base plate.

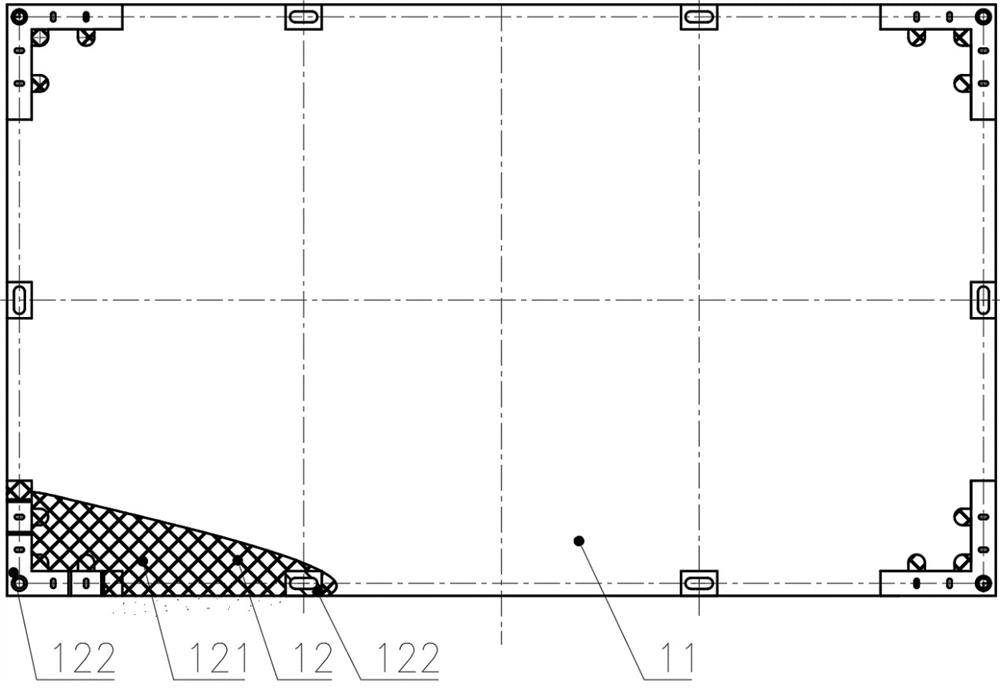

[0038] As shown in Figure 2, the bottom plate component (1) is composed of pouring materials (11) and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com