Gangue throwing machine for mine backfilling and using method thereof

A technology for throwing gangue machines and mines, which is applied to filling materials, mining equipment, earth cube drilling and mining, etc. It can solve the problems of large space occupation, poor backfilling effect, and insufficient backfilling, and achieve good backfilling effect, small space occupation, and filling high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly describe the technical characteristics of the present plan, the plan will be described below by way of example.

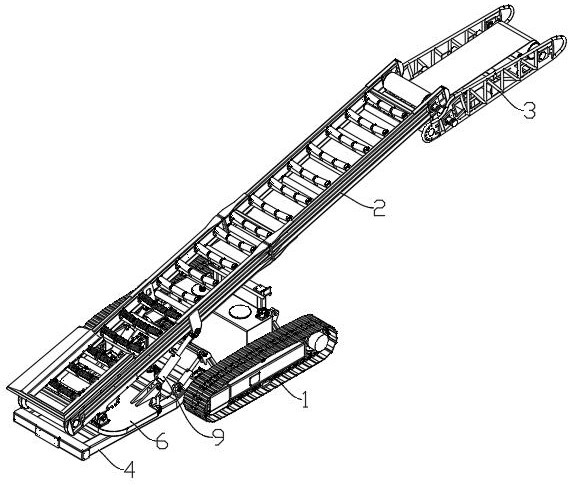

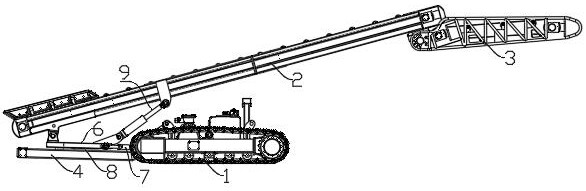

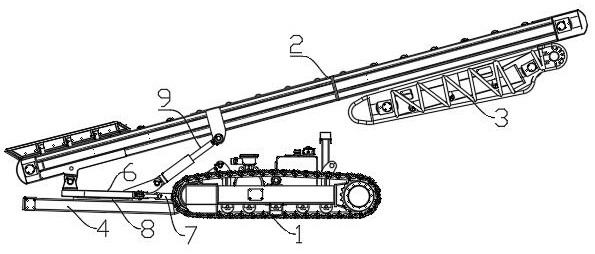

[0037] like Figure 1 ~ 7 As shown, a mine back filling of the present invention, including the travel mechanism 1, the main belt conveyor 2, and the end belt conveyor 3, the travel mechanism 1 is the crawler traveling mechanism, which can accommodate complex in the mineral cave. The road condition, which is convenient to advance, backward, and steering, the upper end described in this application is not necessarily the uppermost position, and also includes positions close to the upper end, the lower ends described in this application are not necessarily the position, also Contains positions close to the lower end.

[0038] The main belt conveyor 2 is tilted and hinges with the traveling mechanism 1, the main belt conveyor 2 throws the material upward, the front side of the throwing direction is the front side of the throwing machine, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com