Multi-point correction method for Fisher particle size analyzer

A Fibonacci particle size and multi-point correction technology, which is applied in the detection and analysis of powder metallurgy, metal powder and hard alloy materials, can solve the problems of equipment air pressure changes, influence detection systems, changes, etc., to achieve consistent detection systems and solve problems The effect of systematic differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

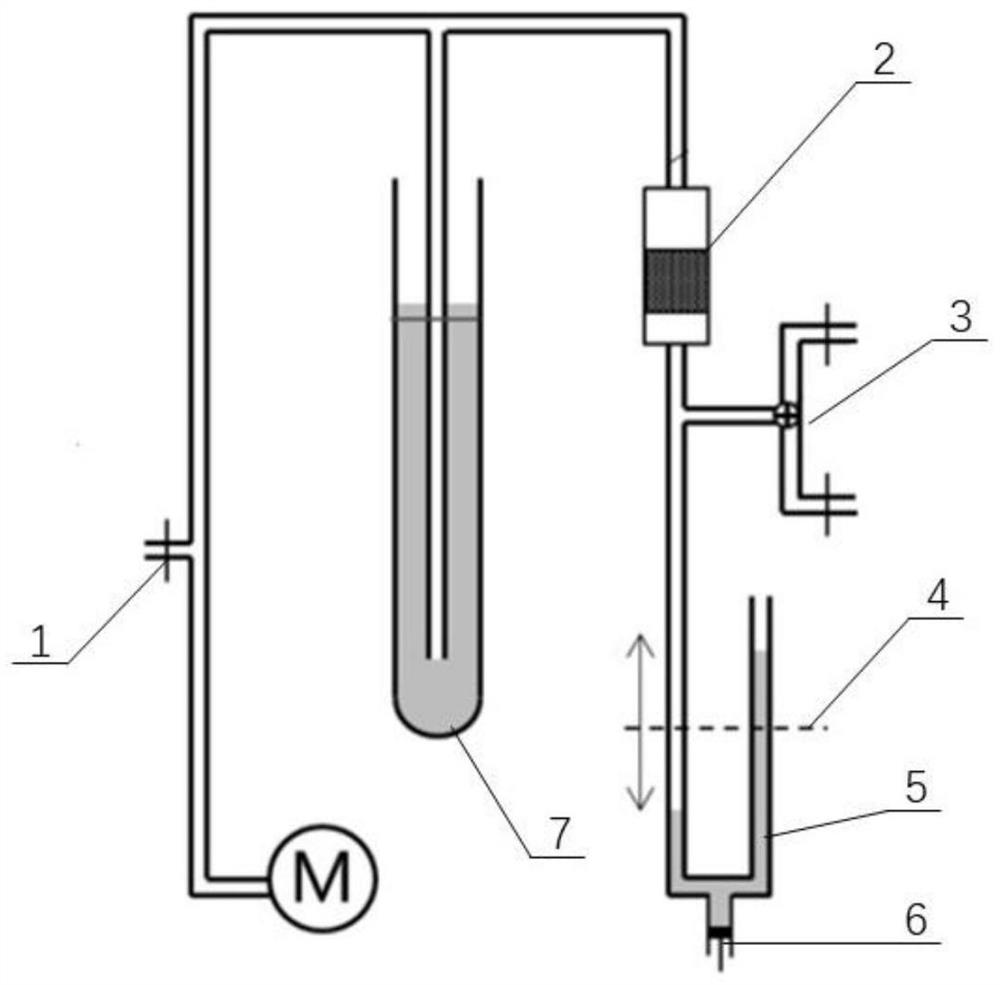

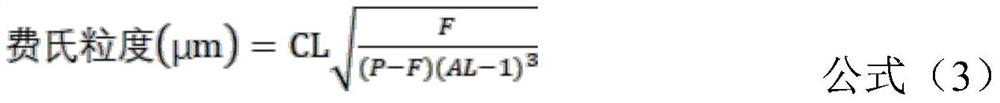

[0030] The WLP-208 Fisher Particle Size Analyzer was calibrated with the Fisher 95 Particle Size Analyzer as the debugging standard. The working principle diagram of the Fischer particle size analyzer in this embodiment is as follows figure 1 As shown, it includes a pressure stabilizing valve 1, a sample tube 2, a needle valve behind the tube 3, a reading plate baseline 4, a U-shaped tube 5, a water replenishing valve 6 and a stabilizing tube 7. The specific calibration method is: adjust the equipment to the low gear position, weigh 15.7g of calibration substance WC-A (0.5um) and calibration substance WC-B (10.0um), put them into the sample tube, press them into the porous brass sieve, and placed on the support column. Move the rack until the bottom surface of the rack is in contact with the brass screen in the sample tube, turn the handwheel, and apply 222N pressure repeatedly 3 times. Read the Fischer particle size value of WC-A at 0.500 porosity, and read the Fischer part...

Embodiment 2

[0037]Calibrate the WLP-208 Fischer particle size analyzer with the standard value of the ruby standard tube as the calibration reference. The specific calibration method is as follows: adjust the equipment to a low gear, and select ruby standard tube 1 (2.30um) and ruby standard tube 2 (1.85um) for calibration. Read the Fischer particle size value of ruby standard tube 1 (2.30um) at 0.700 porosity, and read the Fischer particle size value of ruby standard tube 2 (1.85um) at 0.750 porosity. Calculate the L value according to formula 2, then calculate the water column height of ruby standard tube 1 (2.30um) and ruby standard tube 2 (1.85um) according to formula 3, and calculate the K value of the WLP-208 Fischer particle size analyzer. Debug the low-grade needle valve so that K 测量 with K 标准 unanimous. Then adjust the water level of the voltage regulator tube so that the difference between the Fischer value and the standard value of the ruby standard tube 1 (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com