Hot bending bent pipe fan-shaped corrosion prevention operation device and corrosion prevention operation method

A technology of operating device and heating device, which is applied in pipeline anti-corrosion/rust protection, damage protection, pipeline protection, etc. It can solve problems affecting product qualification rate, low processing efficiency, disadvantages, etc., to ensure anti-corrosion processing effect and improve operation Efficiency, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

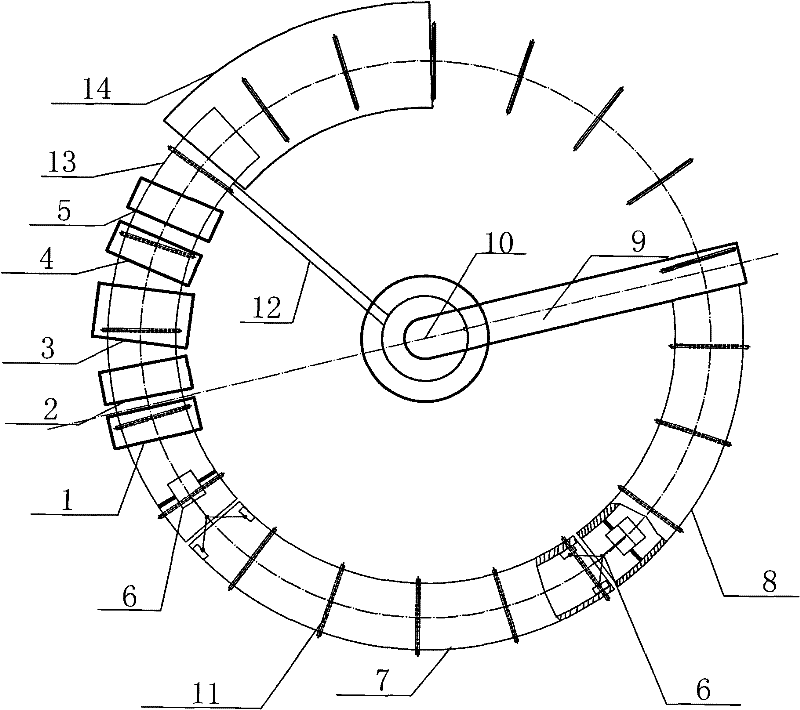

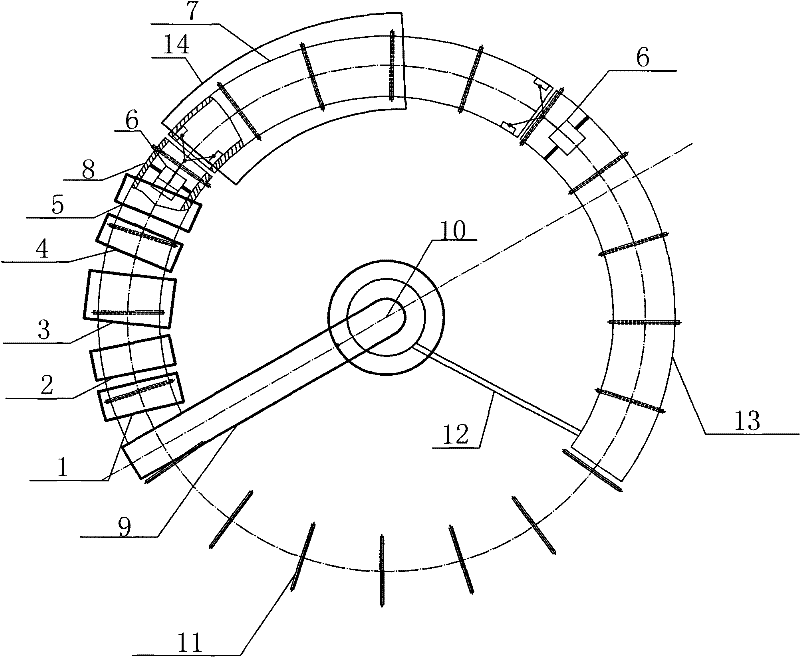

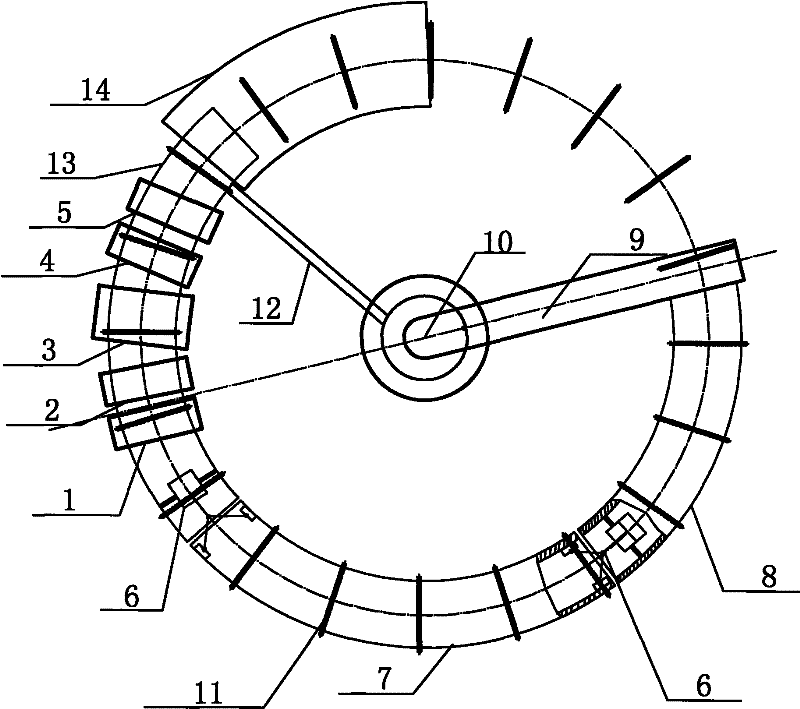

[0054] The invention discloses a 7-sector anti-corrosion operation device for hot-bending elbows, which includes an intermediate frequency heating device 1, a powder spraying device 2 and a winding device 3, and also includes a rotating shaft 10, on which a rotating shaft 10 is fixedly connected. Driven active arm 9 is provided with a first arc-shaped curved arm 8 on the active arm 9. Driven by the active arm 9, the motion track of the first arc-shaped curved arm 8 is circular, that is, with the rotary shaft 10 as the center of the circle , the active arm 9 is the radius, and the trajectory of the arc-shaped curved arm is a circle. On the rotary shaft 10, the passive arm 12 that rotates around the rotary shaft 10 is hinged, and the passive arm 12 is provided with a second arc-shaped curved arm 13. 7 is fixedly connected between the first curved arm 8 and the second curved arm 13, and the bending ratio between the first curved arm 8, the second curved arm 13 and the curved pipe ...

Embodiment 2

[0056] On the basis of Example 1, the more preferred technical solution of the present invention is: a secondary heating device 4 located outside the winding device 3 is arranged below the circular motion track, and the curved pipe 7 is sequentially connected with the intermediate frequency heating device 1 and the powder The spraying device 2, the winding device 3 and the secondary heating device 4 cooperate. A secondary rolling device 5 located outside the secondary heating device 4 is arranged below the circular motion track, and the elbow 7 is sequentially connected with the intermediate frequency heating device 1, the powder spraying device 2, the winding device 3, the secondary heating device 4 and the The secondary rolling device 5 cooperates. A cooling device is arranged below the circular motion track, and the cooling device is a common water shower or other forms. The secondary heating device 4 is a far infrared heater. The secondary rolling device 5 is a spring wh...

Embodiment 3

[0058] At the same time, the present invention also provides a fan-shaped anti-corrosion operation method for hot-bending bent pipes, which includes the following process steps:

[0059] a. Fix the bent pipe after shot blasting and derusting on the anti-corrosion operation device, that is, connect and fix the bent pipe with the first curved arm and the second curved arm;

[0060] b. The rotation of the rotary shaft drives the first arc-shaped curved arm on the active arm to rotate, and the curved pipe also rotates under the drive of the first curved curved arm. The curved arm, the second arc curved arm and the curved pipe all move on the track;

[0061] c. Pass the elbow through the intermediate frequency heating device, powder spraying device and winding device in sequence to complete the three-layer PE anticorrosion of the elbow. When passing through the intermediate frequency heating, the temperature difference is controlled to be ≤±10°C;

[0062] d. Send the three-layer P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com