Data analysis system for industrial site side cloud collaboration and implementation method

A data analysis system and industrial site technology, applied in database distribution/replication, transmission system, structured data retrieval, etc., can solve problems such as data delay, model cannot be updated in time, and edge computing resources are limited, so as to enhance adaptability , breaking information islands and improving the efficiency of bandwidth resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

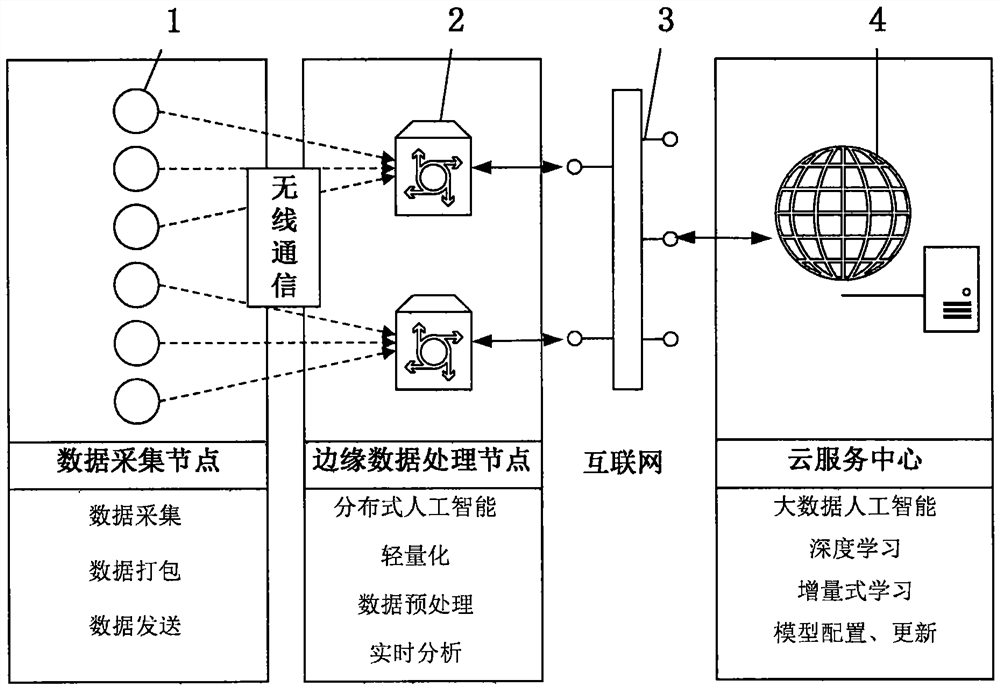

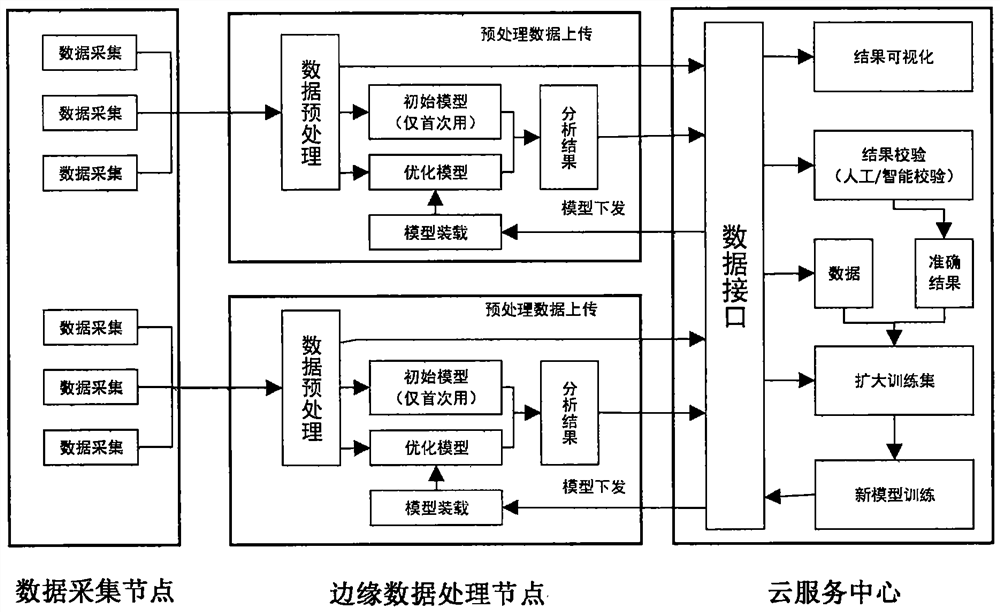

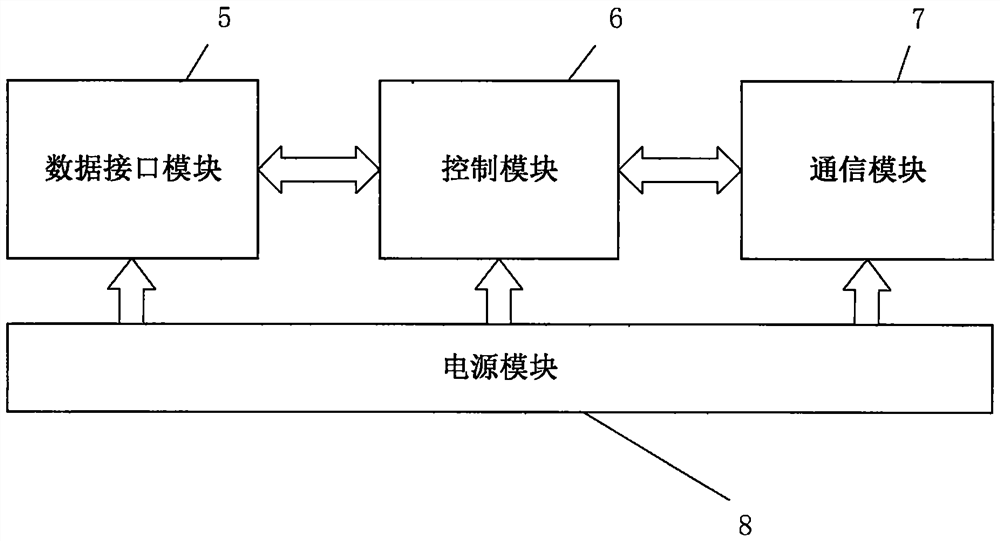

[0027] The present invention is a data analysis system for edge-cloud collaboration in industrial sites, such as figure 1 As shown, the system consists of the following parts: data acquisition node 1, edge data processing node 2, and cloud service center 4. Among them, the data acquisition nodes are equipped with sensors or general data interfaces to collect industrial field data in real time; the edge data processing nodes use general-performance CPUs and lightweight AI chips, and are equipped with distributed artificial intelligence models to preprocess and analyze industrial data in real time. Analyze the results, display the results in real time, and send the preprocessed data and analysis results to the cloud; the cloud service center uses high-performance cloud hosts, equipped with big data artificial intelligence models, and summarizes the analysis results and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com