Sewage sedimentation tank capable of separating floating objects for sewage treatment

A technology for sewage treatment and floating matter, which is applied in the direction of filtration separation, sedimentation separation, separation methods, etc., can solve the problems of increasing the burden on laborers and threatening the safety of laborers, and achieve the effect of improving cleanliness and improving filtration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

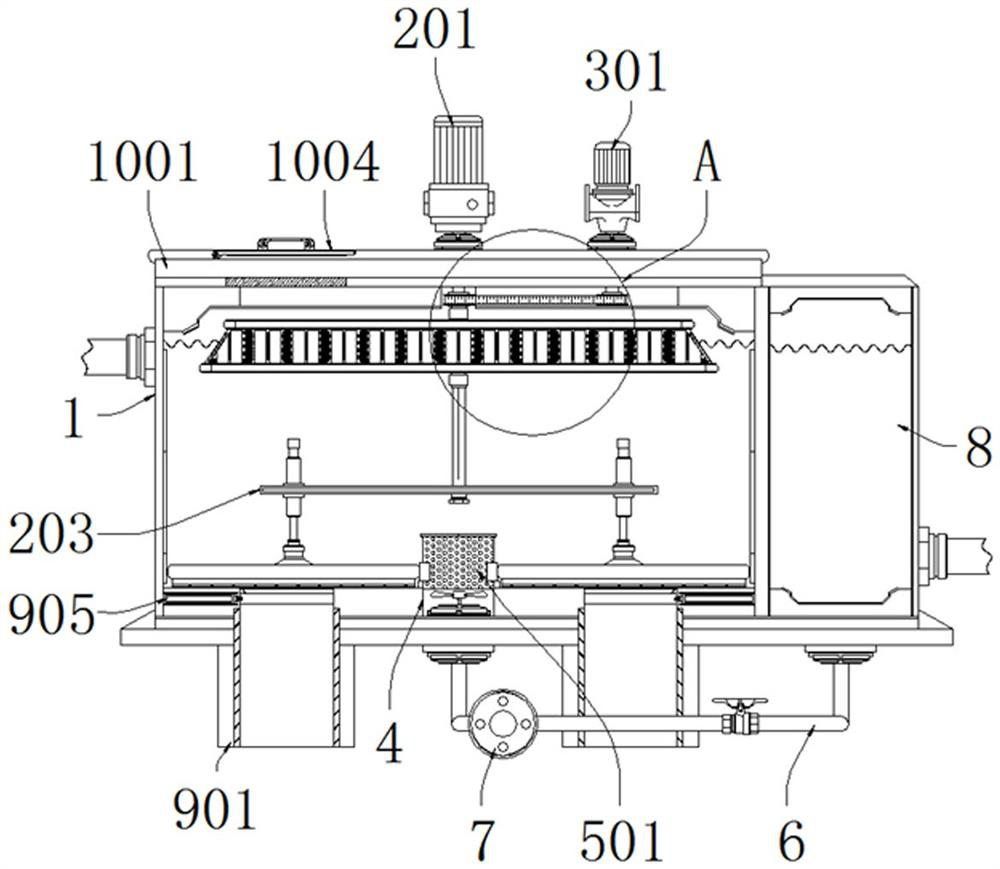

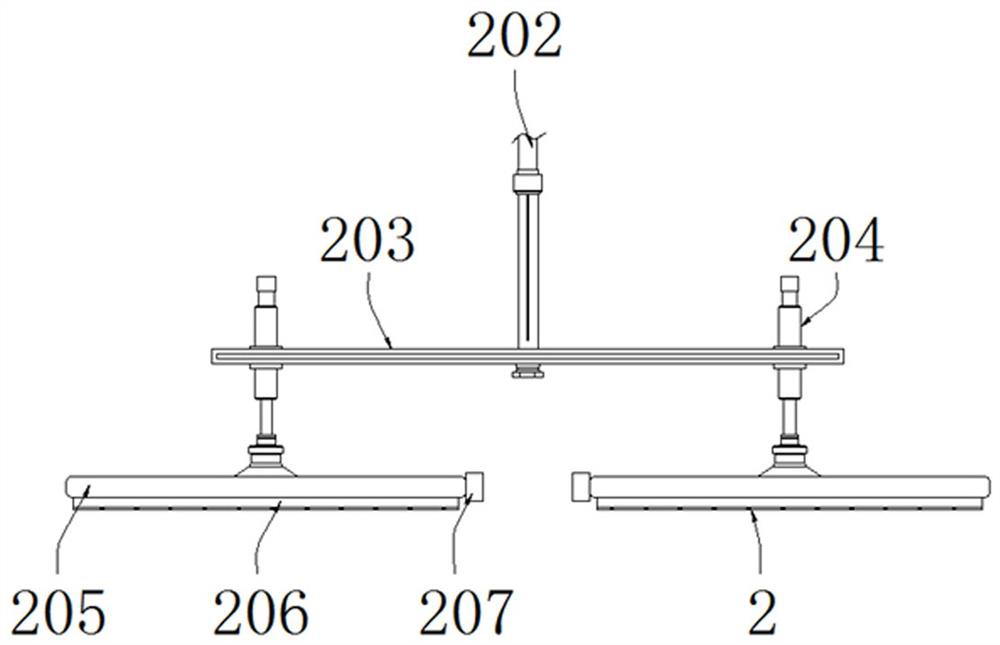

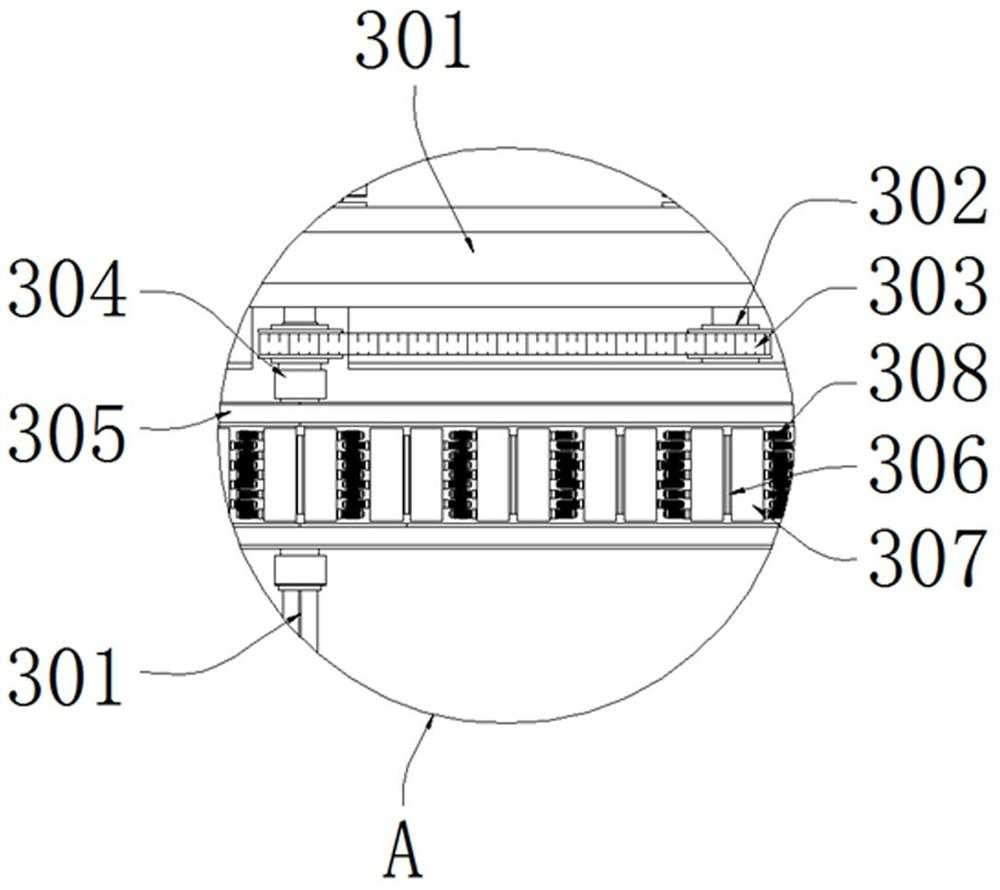

[0028] see Figure 1-7, the present invention provides a technical solution: a sewage sedimentation tank for sewage treatment that can separate floating matter, including a tank body 1 and a mud discharge assembly 9, a mud removal assembly 2 is installed on the top of the pool body 1, and the mud removal assembly 2 is a A separation component 3 is installed on the side, a groove 4 is opened in the middle of the lower part of the pool body 1, and a filter component 5 is arranged inside the groove 4, a connecting pipe 6 is connected to the bottom of the filtering component 5, and a booster pump 7 is installed outside the connecting pipe 6 , the other end of the connecting pipe 6 is connected with a disinfection pool 8, and the mud discharge assembly 9 is installed on both sides of the bottom of the pool body 1. The mud cleaning assembly 2 includes a driving motor 201, a coupling shaft 202, a placement frame 203, a telescopic rod 204, and a mud cleaning plate 205 , scraper 206 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com