Full-automatic high-purity PFA fluoroplastic injection molding machine and injection molding process thereof

An injection molding machine and high-purity technology, applied in the field of automatic high-purity PFA fluoroplastic injection molding machine and its injection molding process, can solve the problems of easy collision of raw materials, low work efficiency, damage, etc. Improve work efficiency and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

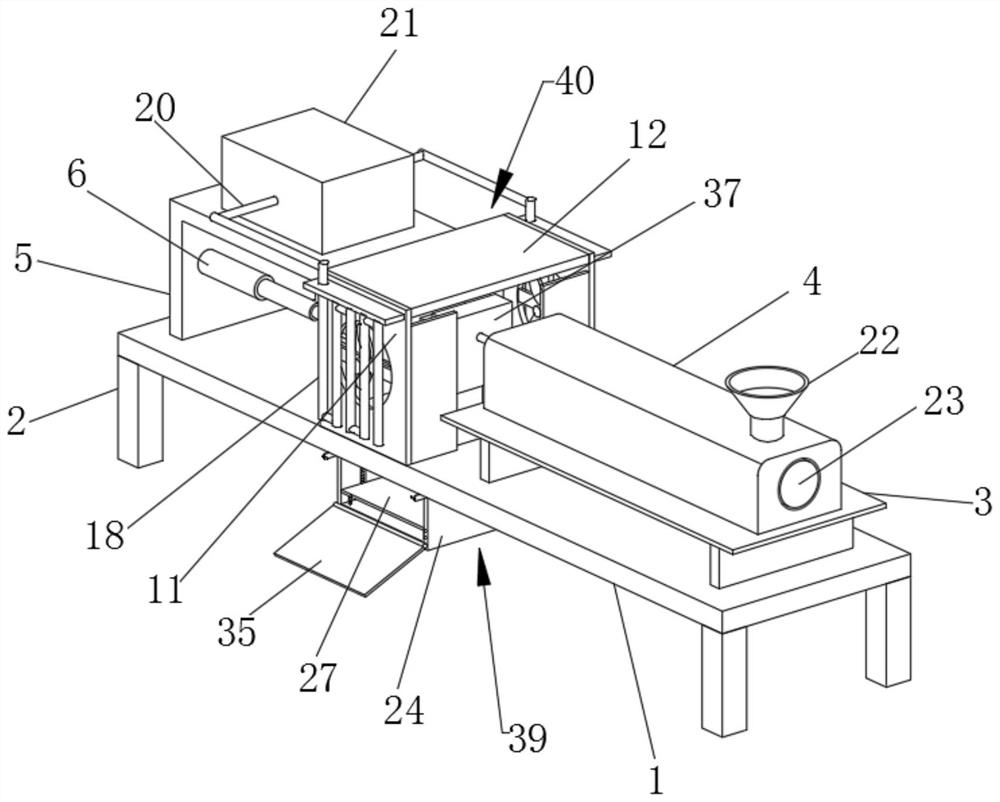

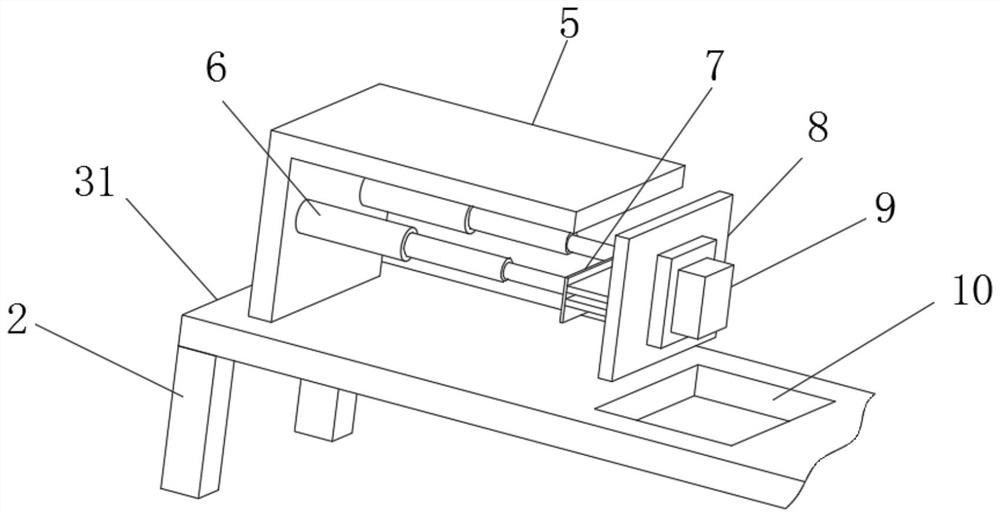

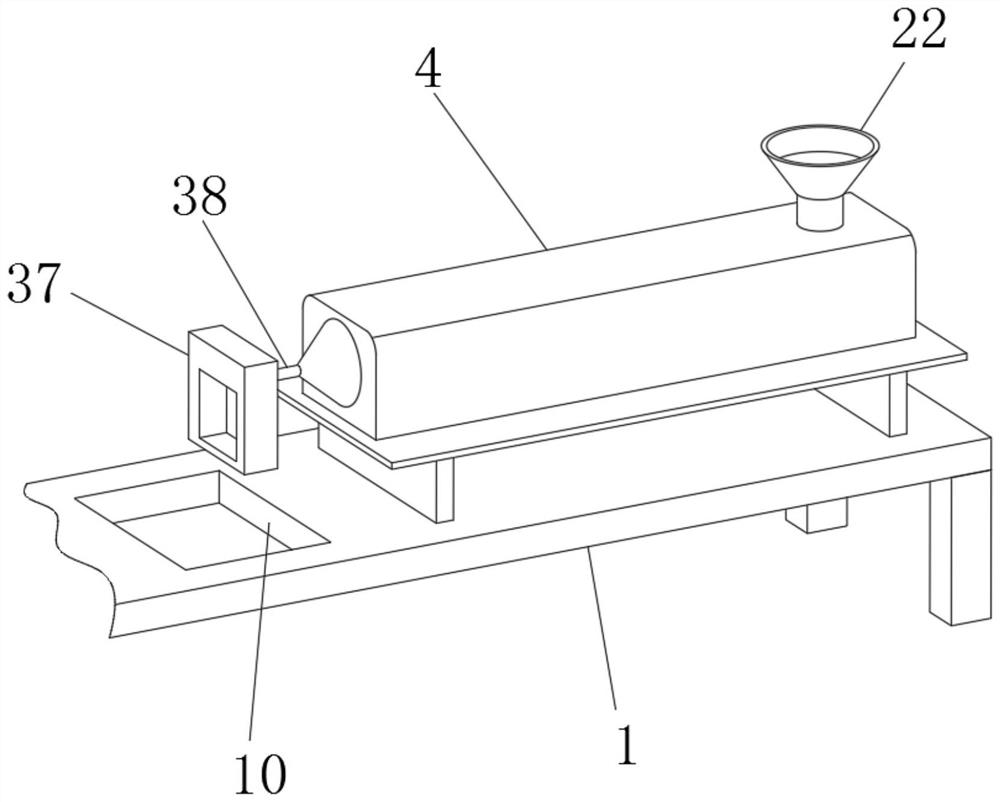

[0032] see Figure 1-6 , the present invention provides a technical solution: a fully automatic high-purity PFA fluoroplastic injection molding machine and its injection molding process, including a base plate 1, the bottom surface of the base plate 1 is equipped with support rods 2 near the four corners, and the upper surface of the base plate 1 is close to a The side position is equipped with an L-shaped support plate 5, and the inner wall of the L-shaped support plate 5 is equipped with an electric telescopic rod-6, and one end of the electric telescopic rod-6 is equipped with a connecting frame 7, and the outer surface of the connecting frame 7 is connected with a square plate 8. A mold one 9 is installed on the outer surface of the template 8, a square groove 10 is formed on the upper surface of the bottom plate 1 near the middle position, and a collection mechanism 39 is arranged on the bottom surface of the bottom plate 1 and below the square groove 10, and the upper sur...

Embodiment 2

[0038] see Figure 1-6 , the present invention provides a technical solution: a full-automatic high-purity PFA fluoroplastic injection molding machine and its injection molding process, including a bottom plate 1, six groups of garbage bins 2 are symmetrically arranged on the upper end of the bottom plate 1, and the upper ends of the six groups of garbage bins 2 are arranged Four sets of holding grooves 3 are provided, and two sets of vertical brackets 1 and 4 are arranged on the upper end of the bottom plate 1 close to the middle position, and two sets of vertical brackets 2 and 5 are arranged on one side of the vertical bracket 1 4, and the left and right sides of the vertical bracket 1 4 A conveyor belt 6 is arranged between the walls, an identification module 17 is arranged at the upper end of two sets of vertical brackets 1 near the front end, a protective plate 22 is arranged between the vertical bracket 1 4 and the vertical bracket 2 5, and the upper end of the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com