Process for producing thymidine by fermentation method

A fermentation method and technology of thymidine, applied in the field of β-thymidine preparation, can solve the problems of increasing production cost, low production efficiency, low utilization rate of culture medium, etc., so as to improve utilization rate, reduce processing cost and enhance practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

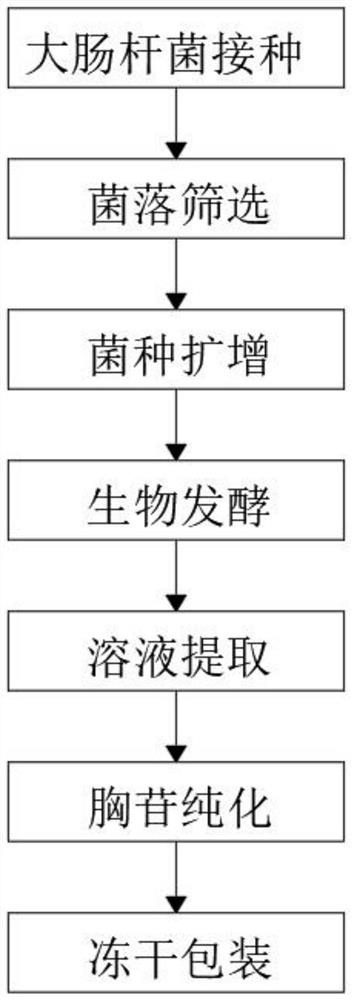

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a process for producing thymidine by fermentation, including inoculation, screening, amplification, fermentation, extraction and purification. The specific process flow is:

[0034] S1. Vaccination

[0035] In a sterile environment, spread and inoculate the culture medium with Escherichia coli strains that have been implanted with relevant genes, put them into the culture room, and carry out colony cultivation. The culture dish is GYT medium, and the colony cultivation time is 24 hours;

[0036] S2. Screening

[0037] After the colony cultivation is completed, in a sterile environment, screen and cut off the colonies that reproduce faster, make a dispersion, and take 2ml of the dispersion for 1000-fold dilution, and detect the number of E. coli in the unit volume of the dispersion;

[0038] S3. Amplification

[0039] The prepared dispersion liquid is evenly mixed into the liquid medium at a r...

Embodiment 2

[0047] The difference between this example and Example 1 is that the production process of thymidine by fermentation method includes inoculation, screening, amplification, fermentation, extraction and purification, and the specific process flow is as follows:

[0048] S1. Vaccination

[0049] In a sterile environment, spread and inoculate the culture medium with Escherichia coli strains implanted with relevant genes, put them into the culture room, and carry out colony cultivation. The culture dish is GYT medium, and the colony cultivation time is 36 hours;

[0050] S2. Screening

[0051] After the colony cultivation is completed, in a sterile environment, screen and cut off the colonies that reproduce faster, make a dispersion, and take 2ml of the dispersion for 1000-fold dilution, and detect the number of E. coli in the unit volume of the dispersion;

[0052] S3. Amplification

[0053] Mix the prepared dispersion evenly into the liquid medium at a ratio of 1:100, put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com