High-strength steel and preparation method thereof

A high-strength steel and body technology, applied in the field of high-strength steel and its preparation, can solve problems such as surface pits, unhealthy workers, iron sheet accumulation, etc., and achieve excellent formability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

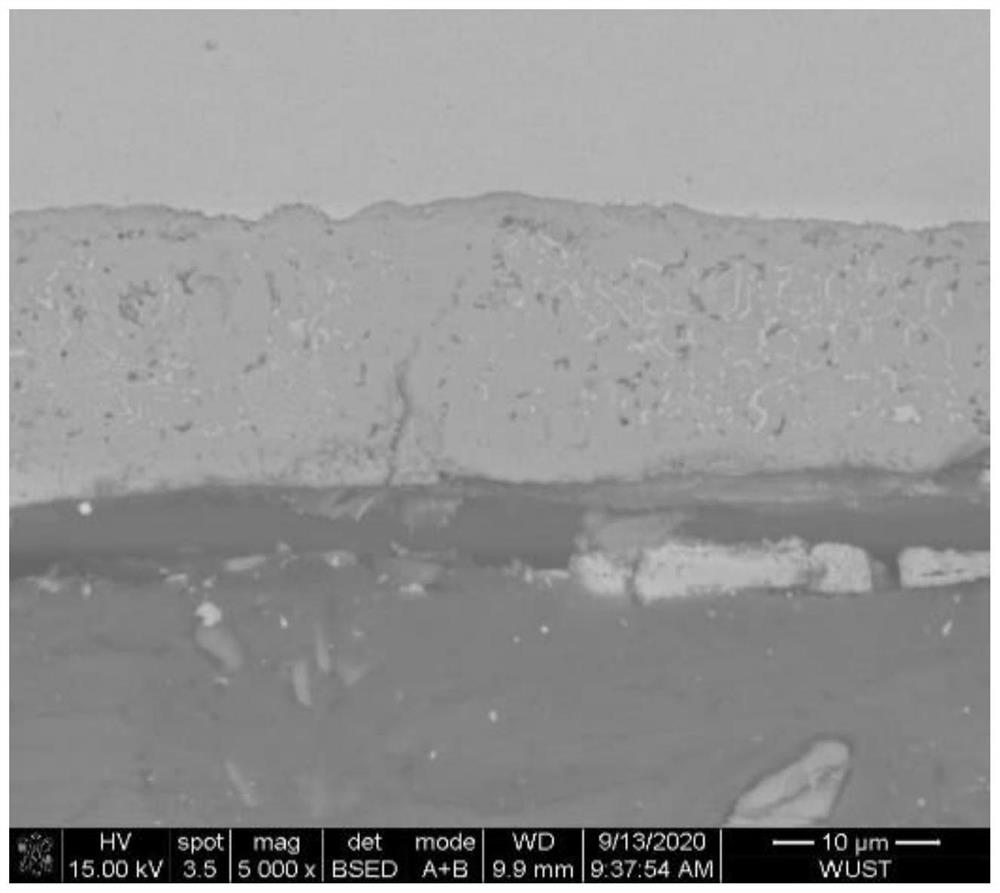

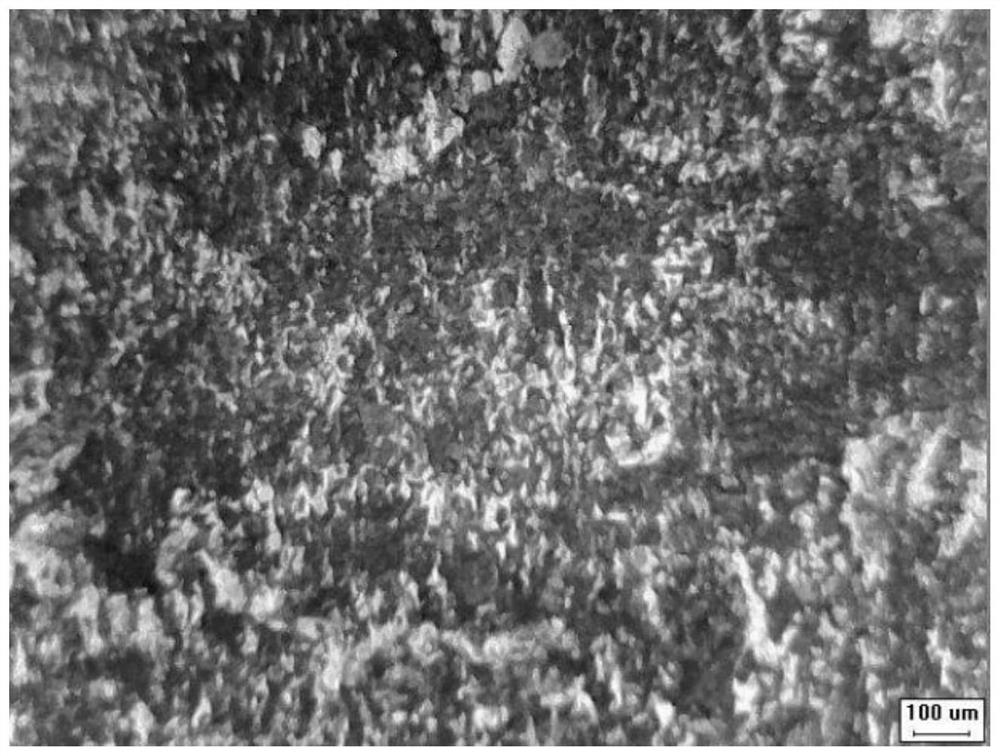

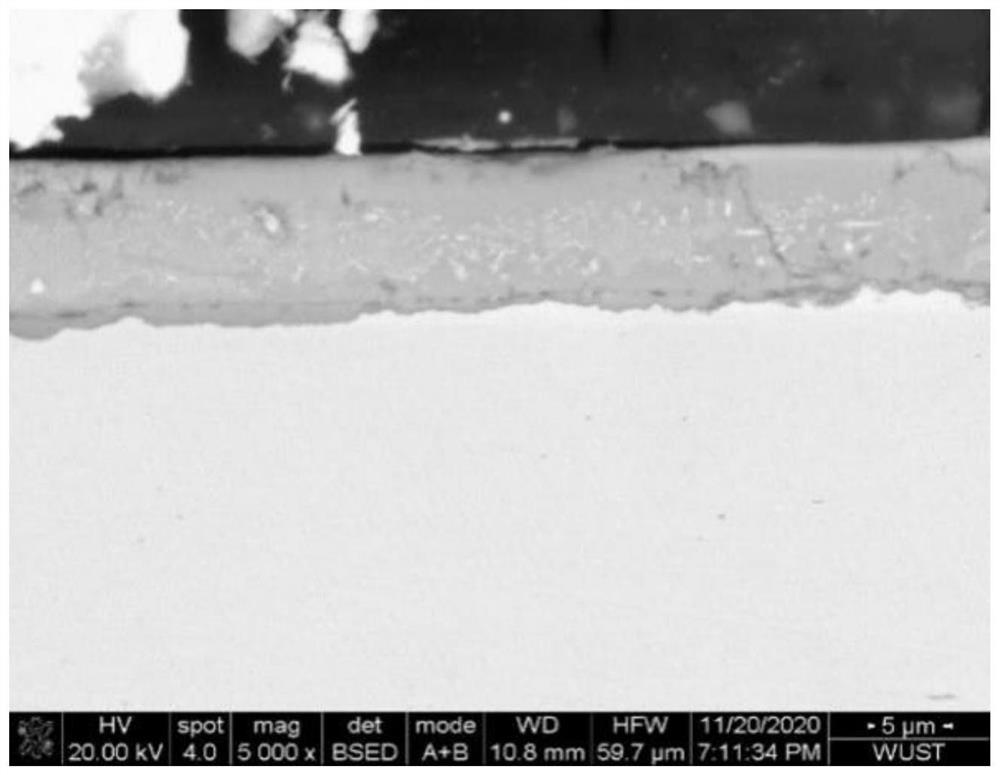

Image

Examples

preparation example Construction

[0059] Preparation of high-strength steel

[0060] Embodiments of the second aspect of the present invention provide a method for preparing high-strength steel, the method comprising the steps of:

[0061] 1) Carry out heat treatment to billet;

[0062] 2) descaling and rolling, the finish rolling temperature in the rolling is 850-920°C;

[0063] 3) laminar flow cooling, the laminar flow cooling adopts front-end centralized cooling;

[0064] 4) coiling, the coiling temperature is 550~610°C;

[0065] 5) Natural air cooling to obtain the high-strength steel.

[0066] In some embodiments, the heat treatment in step 1) specifically includes heating the steel slab to 1200-1250° C. within 120-180 minutes and keeping it warm for at least 30 minutes.

[0067] It should be noted that the heat treatment in step 1) is specifically to heat the billet to 1200-1250°C within 120-180 minutes, and keep it warm for at least 30 minutes. The purpose is to completely dissolve the microalloyi...

Embodiment 1

[0079] The chemical composition and content of the high-strength steel are: C is 0.08wt%, Mn is 1.48wt%, Si is 0.08wt%, Nb is 0.056wt%, V is 0.05wt%, Ti is 0.10wt%, Cr is 0.12%, S is 0.002wt%, P is 0.011wt%, and the rest is Fe and unavoidable impurities.

[0080] The slab is heated to 1200°C in a heating furnace and held for 3.5 hours, so that the microalloying elements are completely dissolved and form carbonitrides, which hinder the growth of the original austenite grains and refine the grains.

[0081] After the slab is released from the heating furnace, the furnace scale is removed by high-pressure water for coarse descaling. The descaling speed is 1.0m / min, and the descaling pressure is 20MPa.

[0082] The plate after primary descaling is subjected to rough rolling for 5 passes, and then the base number of rough rolling passes for secondary descaling, followed by fine descaling and high-pressure water for 3 times of descaling, and the descaling pressure is 20MPa.

[0083...

Embodiment 2

[0090] The chemical composition and content of high-strength steel are: C is 0.075wt%, Mn is 1.51wt%, Si is 0.12wt%, Nb is 0.045wt%, V is 0.046wt%, Ti is 0.125wt%, Cr is 0.08 %, S is 0.003wt%, P is 0.015wt%, and the rest is Fe and unavoidable impurities.

[0091] The slab is heated to 1220°C in a heating furnace and kept for 3.2 hours, so that the microalloying elements are completely dissolved and form carbonitrides, which hinder the growth of the original austenite grains and refine the grains.

[0092] After the slab is released from the heating furnace, the furnace scale is removed by high-pressure water for coarse descaling. The descaling speed is 1.0m / min, and the descaling pressure is 20MPa.

[0093] After the primary descaling, the slab is rough rolled for 5 passes, and then the base number of rough rolling passes is used for the second descaling, followed by the fine descaling and high pressure water for 3 descaling, and the descaling pressure is 20MPa.

[0094] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com