Real-time monitoring and displaying system of cold rolling mill for aluminum-titanium alloy processing

A technology of real-time monitoring and display system, applied in the field of aluminum-titanium alloy processing, can solve the problems of affecting the quality of product processing, harsh on-site environment, hearing loss of adjusters, etc., to achieve the effect of improving oil removal efficiency and improving plate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

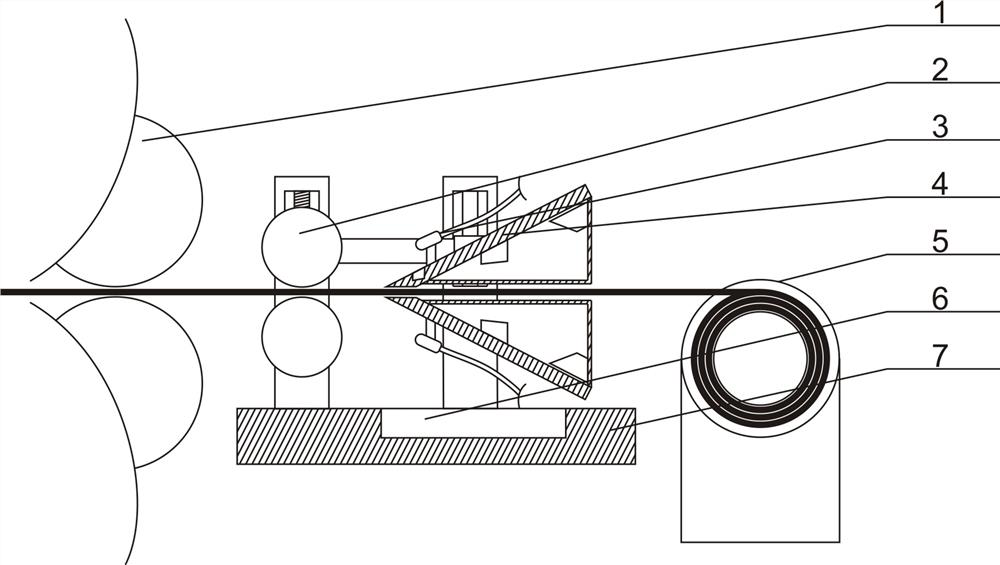

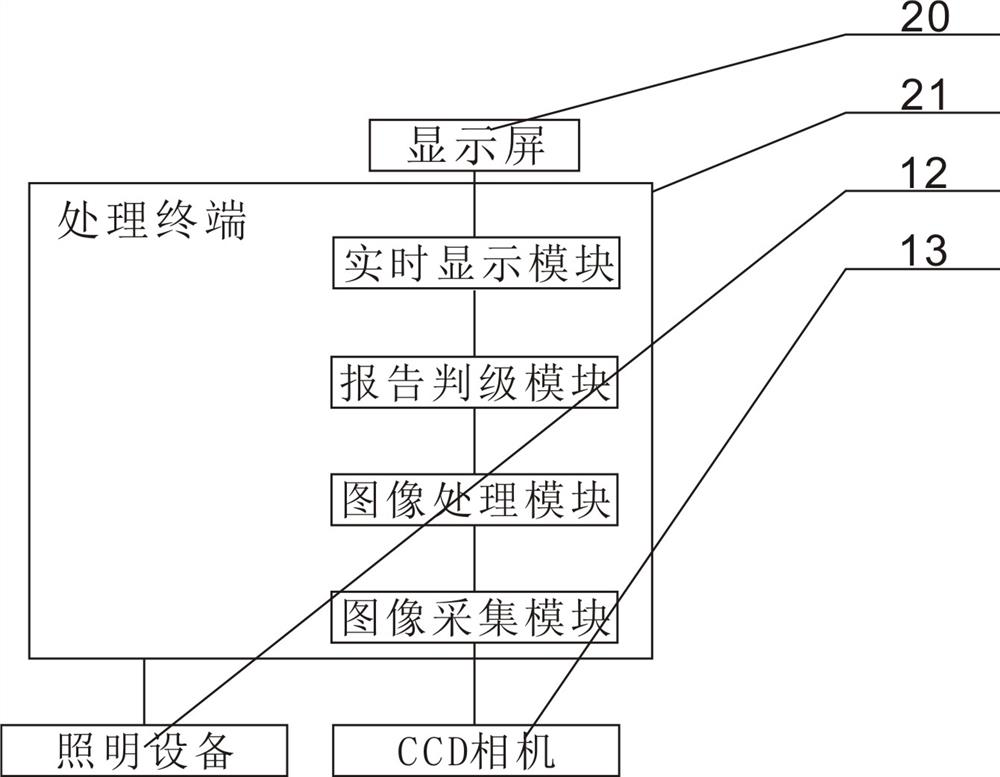

[0033] Embodiment 1, a real-time monitoring and display system for a cold rolling mill for aluminum-titanium alloy processing, including a bottom plate 7 installed between the discharge end 1 of the cold rolling mill and the winding mechanism 5 of the cold rolling mill. The degreasing mechanism 4 for degreasing the upper and lower surfaces of the aluminum strip, and the rear part of the degreasing mechanism 4 is equipped with a monitoring and display system for real-time monitoring and display of the surface quality of the aluminum strip;

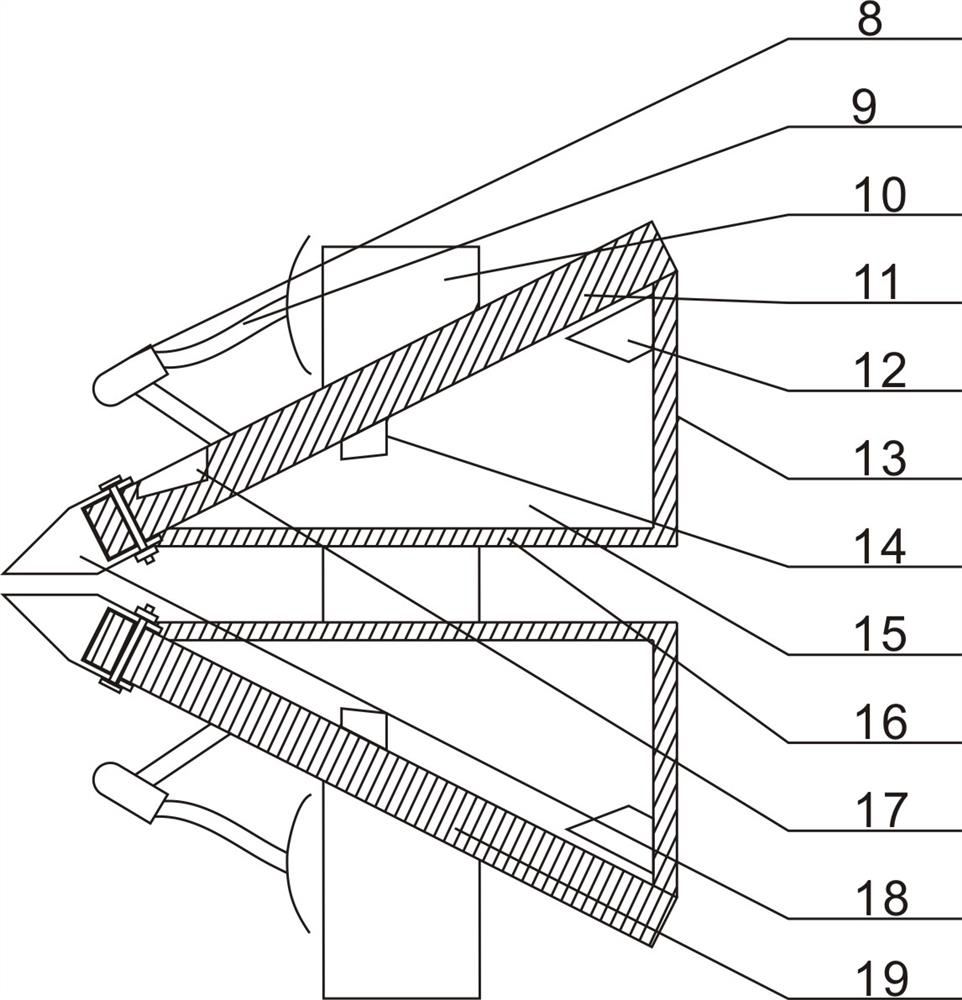

[0034]Specifically, the degreasing mechanism 4 includes a support rod A10, an upper scraper 11 and a lower scraper 19. Two symmetrically arranged support rods A10 are arranged on both sides of the upper surface of the bottom plate 7, and the upper parts of the rod bodies of the two support rods A10 are provided with The opening slot A24, the opening slot A24 is rotatably connected with the screw rod 25 arranged along the length direction of ...

Embodiment 2

[0038] Embodiment 2, in order to ensure the degreasing efficiency of the degreasing mechanism 4, the distance between the upper scraper 11 and the lower scraper 19 should just match the thickness of the aluminum strip, and the aluminum strip can maintain The level is stable, therefore, the front part of the degreasing mechanism 4 is provided with a guiding and calibrating mechanism 2 for guiding and calibrating the aluminum strip, so that the degreasing mechanism 4 can effectively degrease the upper and lower surfaces of the aluminum strip, and the guiding and calibrating mechanism 2 Including a pole B22, an upper roller 23 and a lower roller 34, two symmetrically arranged poles B22 are arranged on both sides of the upper surface of the bottom plate 7, two symmetrically arranged upper rollers 23 and The lower roller 34, wherein the upper edge of the lower roller 34 is on the same plane as the upper edge of the lower scraper 19 and remains stationary, the lower edge of the upper...

Embodiment 3

[0039] Embodiment 3, since the rolling oil or emulsion oil adheres to the surface of the aluminum strip, it is difficult to completely and effectively clean the oil stains only by the upper scraper 11 and the lower scraper 19. In order to improve the cleaning of the oil stain on the strip surface of the aluminum strip As a result, the upper surface of the upper scraper 11 and the lower surface of the lower scraper 19 are provided with a spraying mechanism 3 for spraying degreaser on the upper and lower surfaces of the aluminum strip output from the discharge end 1 of the cold rolling mill. The spraying mechanism 3 It includes a nozzle 8 and a degreasing agent pipeline 9. One end of the degreasing agent pipeline 9 is connected to the nozzle 8, and the other end is connected to an external degreasing agent through a water pump. The degreasing agent is composed of degreasing powder and corresponding auxiliary reagents. Excellent oil removal effect;

[0040] In order to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com