Assembly adjustment system

A technology for adjusting systems and tooling, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as low efficiency and low quality consistency, achieve efficiency improvement, quality consistency improvement, and improve assembly quality consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

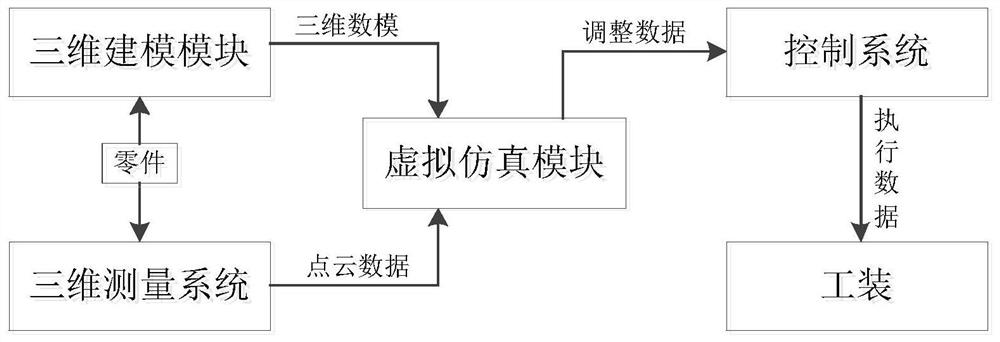

[0014] like figure 1 As shown, an assembly adjustment system of the present invention includes a three-dimensional measurement system, a three-dimensional modeling module, a virtual simulation module, a control system and tooling.

[0015] The three-dimensional measurement system adopts the existing ones, such as three-dimensional laser scanning system, camera or camera. The three-dimensional measurement system obtains the shape data of complex parts with special shapes, that is, the cloud data of a large number of point coordinates on the surface of complex parts with special shapes is obtained by reflecting the surface of parts such as laser and blue light, and the shape of complex parts with special shapes is represented by cloud data.

[0016] The three-dimensional modeling module establishes the three-dimensional digital model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com