Method for manufacturing silicon-based OLED pixel photoetching internally-tangent structure

A manufacturing method and pixel light technology, applied in microlithography exposure equipment, optics, optomechanical equipment, etc., can solve problems such as poor precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

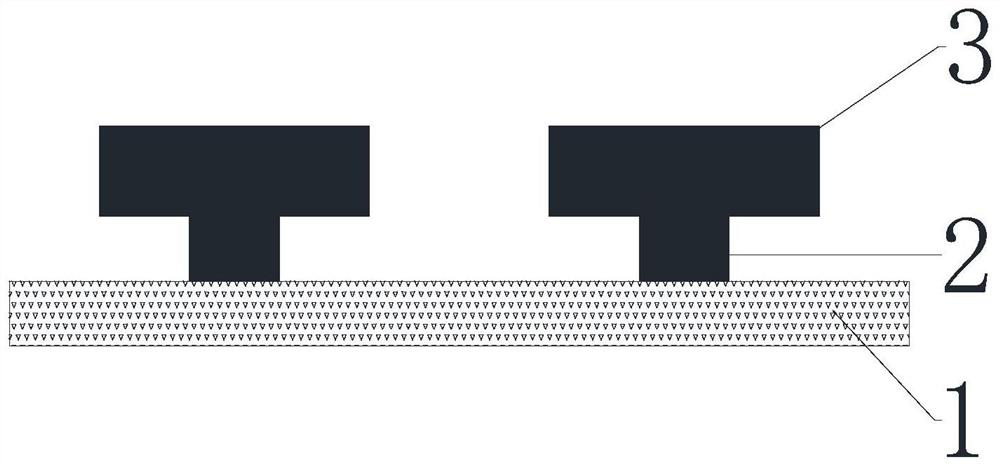

[0039] Embodiment 1: The fabrication method of silicon-based OLED pixel photolithography inscribed structure consists of the following steps:

[0040] Step 1): Coat the 8-inch silicon wafer with a layer Thick positive photoresist B-PR; use a 0.5-1.0 micron line width mask and an i-line photolithography machine with 100-200msec energy to expose the silicon wafer;

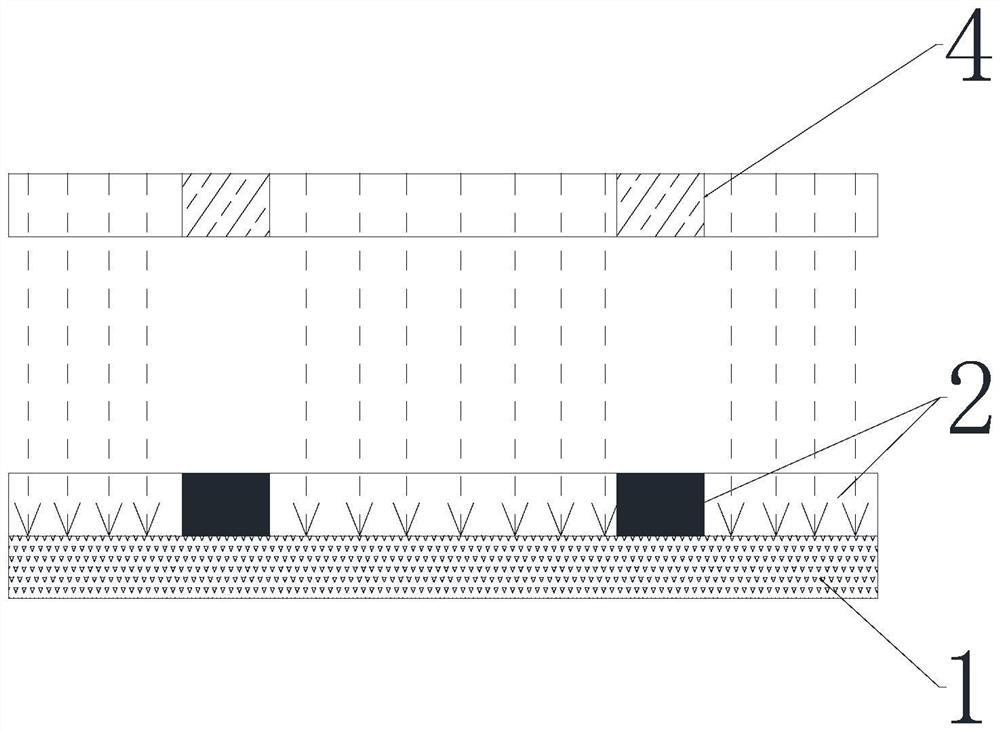

[0041] Step 2): Apply a second coating on the exposed silicon wafer; spin coat a layer on the positive photoresist B-PR Thick positive photoresist T-PR; use 0.5-1.5 micron line width mask, 100-200msec energy i-line photolithography machine to perform secondary exposure on silicon wafers;

[0042] Step 3): Take the exposed silicon wafer to a developing machine for developing, the developing temperature is 80-100°C, and the developing time is 150-200s;

[0043] Step 4): Carry out metal anode evaporation on the silicon wafer, the thickness of the anode layer

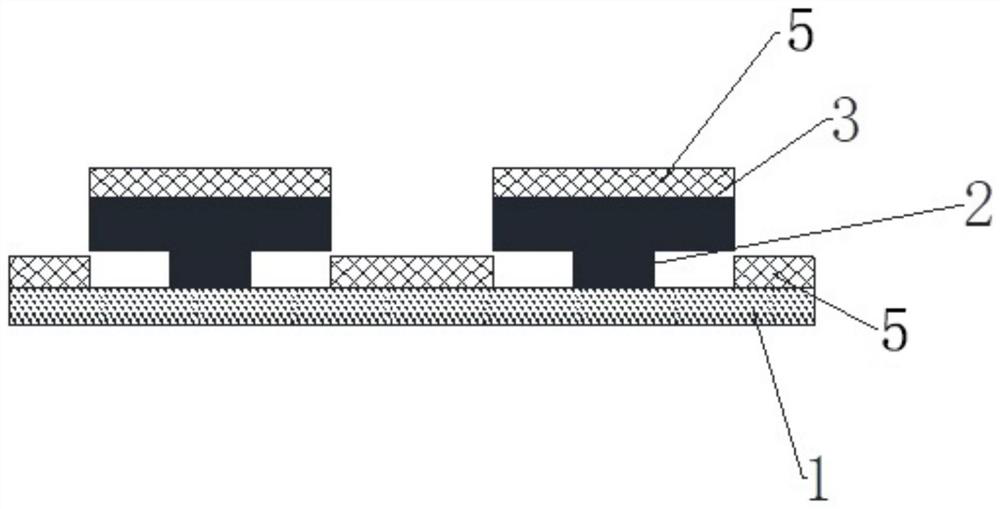

[0044] Step 5): peel off the silicon wafer that has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com