Processing method of patterned beef product

A processing method and technology of beef, applied in the direction of meat processing equipment, processed meat, functions of food ingredients, etc., to achieve the effect of tender texture and improved flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

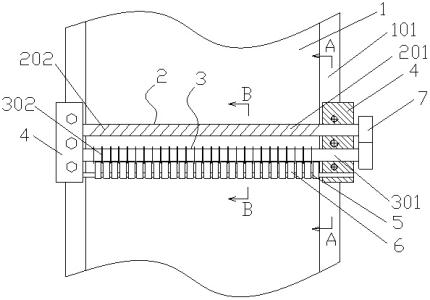

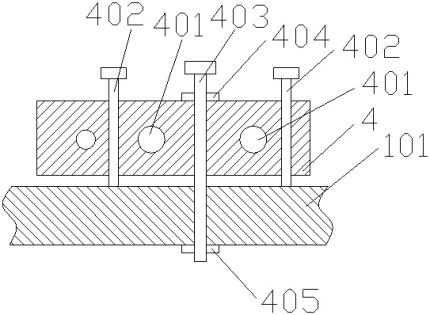

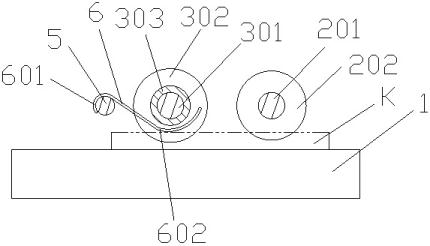

Image

Examples

Embodiment 1

[0048] A processing method for embossed beef products, comprising the following specific steps:

[0049] (1) Wash the fresh beef, cut it into 2cm thick pieces, put it into the tumbler, add tenderizer with 1.5% weight of fresh beef and tumble for 12 minutes, then let it stand for 10 minutes;

[0050] (2) Add appropriate amount of salt, ginger, pepper powder, chili powder, cinnamon powder and marinate for 60 minutes;

[0051] (3) Take out the marinated beef block, and process oblique hob lines and vertical hob lines on the surface of the beef block.

[0052] The raw material composition of the tenderizer in step (1) is calculated in parts by weight: 15 parts of soybean powder, 10 parts of fig pulp, 12 parts of kiwifruit pulp, and 2 parts of salt; wherein the soybean powder is directly ground into fine powder from soybeans; The mashed kiwi fruit is made by mashing the hard raw kiwi fruit with sour fruit.

Embodiment 2

[0054] A processing method for embossed beef products, comprising the following specific steps:

[0055] (1) Wash the fresh beef, cut it into 2cm thick pieces, pour it into the tumbler, add tenderizer with 1% weight of fresh beef and tumble for 10 minutes, then let it stand for 10 minutes;

[0056] (2) Add appropriate amount of salt, ginger, pepper powder, chili powder, cinnamon powder and marinate for 60 minutes;

[0057] (3) Take out the marinated beef block, and process oblique hob lines and vertical hob lines on the surface of the beef block.

[0058] The raw material composition of the tenderizer in step (1) is calculated in parts by weight: 10 parts of soybean powder, 10 parts of fig pulp, 10 parts of kiwifruit pulp, and 2 parts of salt; wherein the soybean powder is directly ground into fine powder from soybeans; The mashed kiwi fruit is made by mashing the hard raw kiwi fruit with sour fruit.

Embodiment 3

[0060] A processing method for embossed beef products, comprising the following specific steps:

[0061] (1) Wash the fresh beef, cut it into 2cm thick pieces, pour it into the tumbler, add tenderizer 2% by weight of fresh beef and tumble for 15 minutes, then let it stand for 10 minutes;

[0062] (2) Add appropriate amount of salt, ginger, pepper powder, chili powder, cinnamon powder and marinate for 60 minutes;

[0063] (3) Take out the marinated beef block, and process oblique hob lines and vertical hob lines on the surface of the beef block.

[0064] The raw material composition of the tenderizer in step (1) is calculated in parts by weight: 20 parts of soybean powder, 20 parts of fig pulp, 20 parts of kiwifruit pulp, and 3 parts of salt; wherein the soybean powder is directly ground into fine powder from soybeans; The mashed kiwi fruit is made by mashing the hard raw kiwi fruit with sour fruit.

[0065] Tenderization experiment

[0066] Embodiment 1 group: the beef bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com