Method for increasing the thickness of tobacco flakes on the lower middle portion of flue-cured Yunnan tobacco and increasing fragrance

A technology of cloud smoke and tobacco sheet, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems that the middle and lower tobacco leaves are difficult to meet the requirements for producing tobacco, the industrial availability of the middle and lower tobacco leaves is poor, and the identity of the middle and lower tobacco leaves is thin, and the like. Promotes photosynthesis, reduces aroma loss, promotes cell division and prolongs effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

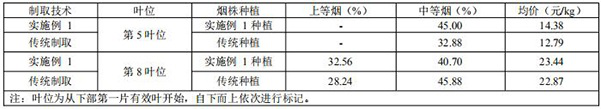

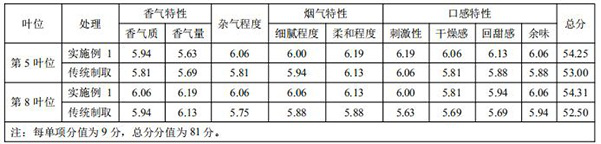

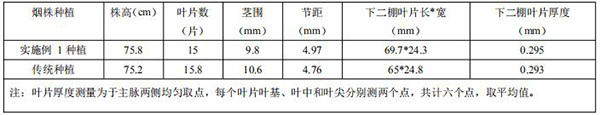

[0020] Embodiment 1: A method for increasing the thickness of the middle and lower tobacco slices of flue-cured tobacco and increasing the aroma, including the following steps: selecting tobacco fields, transplanting on flat ground and appropriately prolonging the cluster period, spraying with brassinolide, and spraying the middle and lower tobacco leaves. Harvest early and enhance the aroma of the middle and lower tobacco leaves; the mentioned aroma enhancement of the middle and lower tobacco leaves includes the following steps: picking and sorting fresh tobacco, layering and densely packing tobacco, changing color at low temperature and medium humidity in the curing room, fixing color at medium temperature and low humidity in the curing room, Medium temperature, medium humidity and dry tendon; the selection criteria for the tobacco field are: windy and humid climate zone, long frost-free period, monthly rainfall of 90-110 mm, relative soil humidity of 50-60%, sunshine percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com