Low-cost high-environment-friendly intelligent copper plate feeding system

An intelligent, low-cost technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of high production safety risks, high labor intensity of workers, and inconvenient convenience, so as to reduce logistics frequency and structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

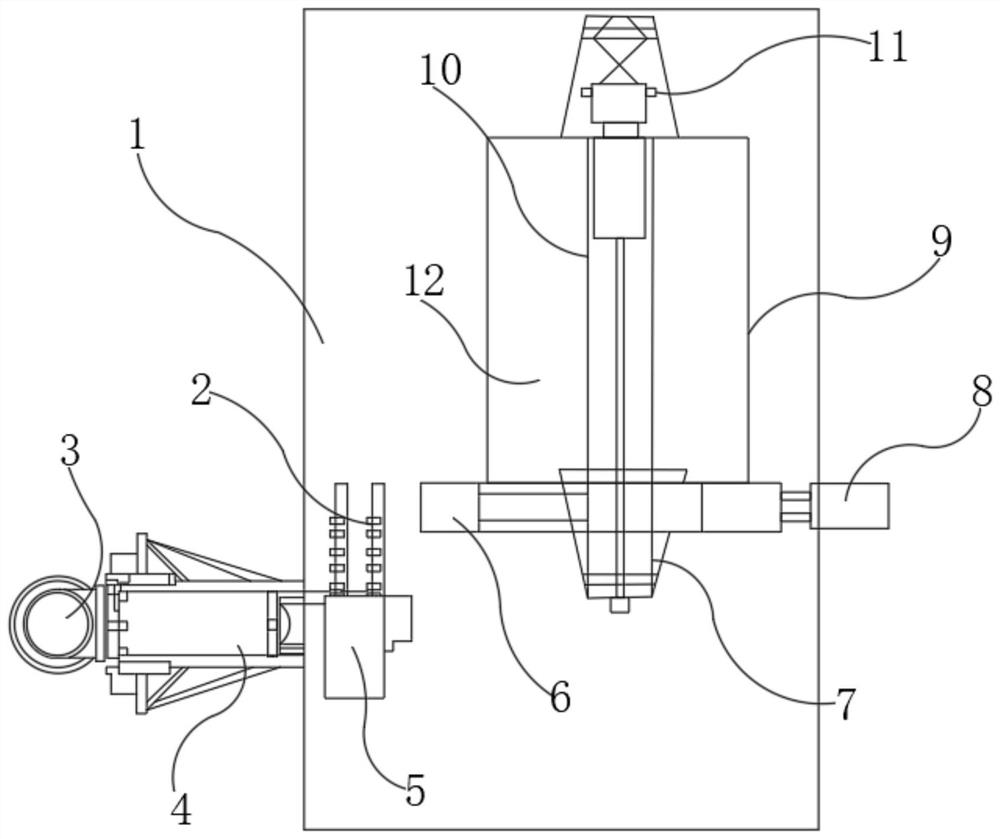

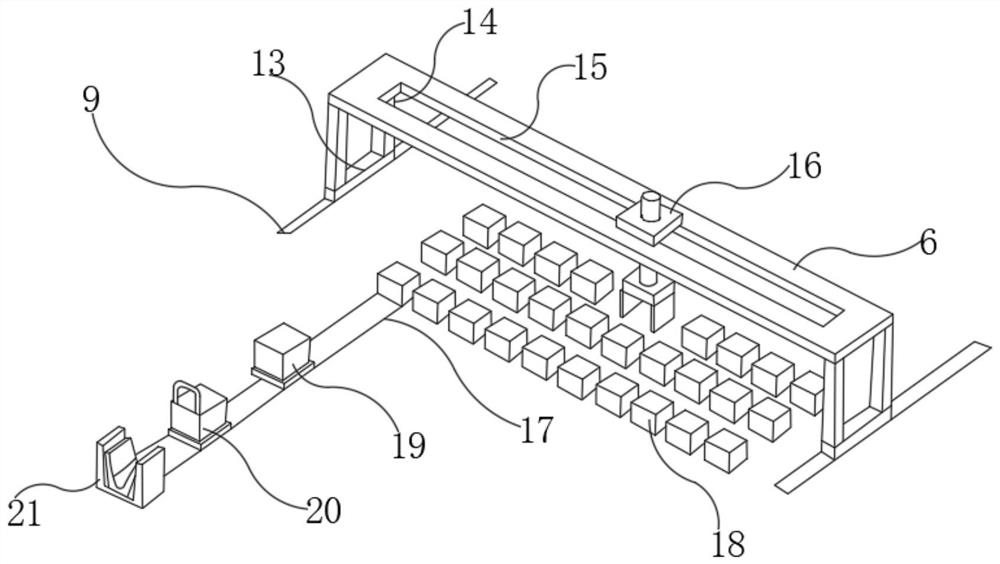

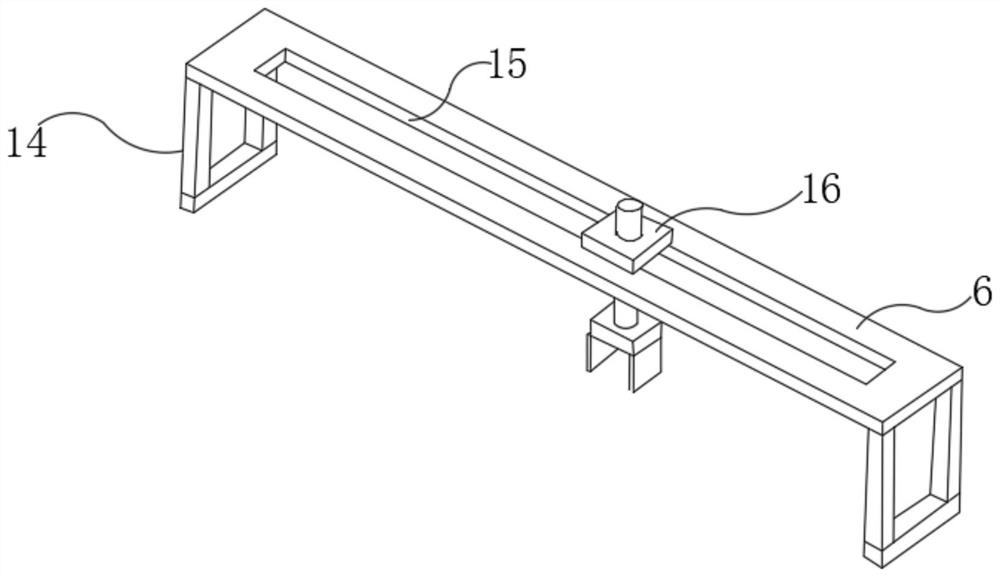

[0028] Such as Figure 1-6 As shown, a low-cost, high-environmental, intelligent copper plate feeding system includes a feeding area 1, the upper end of the feeding area 1 is provided with a material storage area 12, and a No. 9 track 9 is installed at both ends of the material storage area 12. The upper end of No. track 9 is provided with movable feeding seat 6, and No. 1 driver 7 is installed on the front end of movable feeding seat 6, and No. 2 driver 11 is installed on the rear end of movable feeding seat 6, and No. 2 driver 11 and one A connector 10 is arranged between the number drivers 7, a driving rail 8 is installed on the outside of the movable feeding seat 6, a driving mechanism 4 and a feeding rack 5 are installed on one side of the feeding area 1, and the outer side of the feeding rack 5 is installed Feeding mechanism 2 is arranged, and the outside of driving mechanism 4 is installed by feeding seat 3.

[0029] Further, the No. 2 track 17 and the copper plate sto...

Embodiment 2

[0032] Such as Figure 1-6As shown, a low-cost, high-environmental, intelligent copper plate feeding system includes a feeding area 1, the upper end of the feeding area 1 is provided with a material storage area 12, and a No. 9 track 9 is installed at both ends of the material storage area 12. The upper end of No. track 9 is provided with movable feeding seat 6, and No. 1 driver 7 is installed on the front end of movable feeding seat 6, and No. 2 driver 11 is installed on the rear end of movable feeding seat 6, and No. 2 driver 11 and one A connector 10 is arranged between the number drivers 7, a driving rail 8 is installed on the outside of the movable feeding seat 6, a driving mechanism 4 and a feeding rack 5 are installed on one side of the feeding area 1, and the outer side of the feeding rack 5 is installed Feeding mechanism 2 is arranged, and the outside of driving mechanism 4 is installed by feeding seat 3.

[0033] Further, the No. 2 track 17 and the copper plate stor...

Embodiment 3

[0037] Such as Figure 1-6 As shown, a low-cost, high-environmental, intelligent copper plate feeding system includes a feeding area 1, the upper end of the feeding area 1 is provided with a material storage area 12, and a No. 9 track 9 is installed at both ends of the material storage area 12. The upper end of No. track 9 is provided with movable feeding seat 6, and No. 1 driver 7 is installed on the front end of movable feeding seat 6, and No. 2 driver 11 is installed on the rear end of movable feeding seat 6, and No. 2 driver 11 and one A connector 10 is arranged between the number drivers 7, a driving rail 8 is installed on the outside of the movable feeding seat 6, a driving mechanism 4 and a feeding rack 5 are installed on one side of the feeding area 1, and the outer side of the feeding rack 5 is installed Feeding mechanism 2 is arranged, and the outside of driving mechanism 4 is installed by feeding seat 3.

[0038] Further, the No. 2 track 17 and the copper plate sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com