Preparation method of hyperbranched wear-resistant and flame-retardant UV-cured waterborne polyurethane

A water-based polyurethane modification technology, which is applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of restricting the application of water-based polyurethane, poor flame retardancy and water resistance of water-based polyurethane coating films, and achieve good chemical stability Sex, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of hexahydric alcohol:

[0046] a. Add 2.61g THEIC to a clean 50mL beaker, place it in an oil bath magnetic stirring device, set the temperature at 40°C, add 5g DMF to dissolve until the white solid powder disappears completely. Take 6.67g of IPDI in a three-necked flask, add 1-2 drops of DBTDL dropwise, and turn on the stirring device. When the temperature rises to 45°C, slowly add 2.61g of THEIC dissolved in DMF to the three-necked flask, and react for 12 hours;

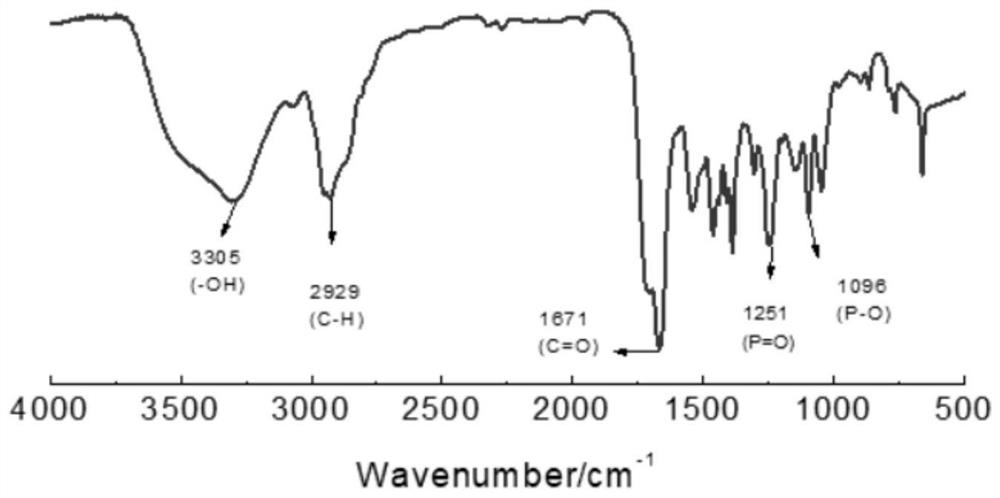

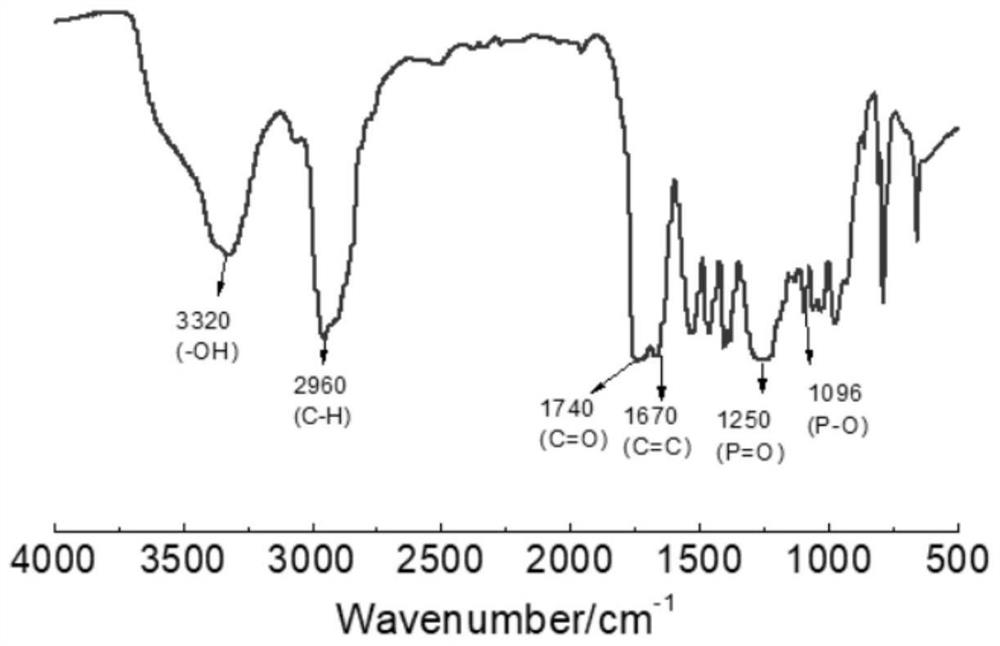

[0047] b. Heat up to 65°C, dissolve 4.20g THPO in 5g DMF, slowly add THPO dropwise to the system at a rate of 4-5s / drop and observe the viscosity of the system. During the dropping process, an appropriate amount of DMF can be added to adjust the viscosity of the system. Reaction After 3 hours, a small amount of sample was taken out for infrared measurement, and it was observed that 2270cm -1 The product was collected and preserved after the peak disappeared, and it was recorded as NP-6OH. T...

Embodiment 2

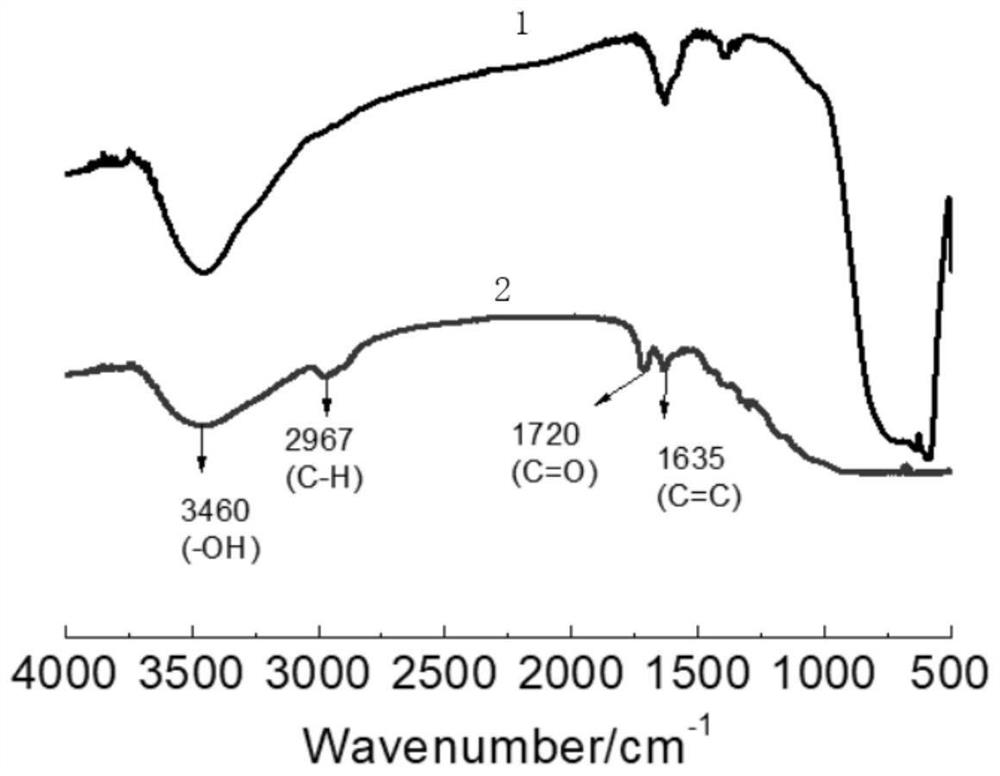

[0062] Add the modified nano-Al prepared by 0.1g step (3) in the step (4) 2 o 3 Slurry, other steps are with embodiment 1.

Embodiment 3

[0064] Add the modified nano-Al prepared by 0.2g step (3) in the step (4) 2 o 3 Slurry, other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com