Assembly type double-sleeve self-resetting energy dissipation steel support with SMA cable

A double-sleeved, assembled technology, applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of unstable self-resetting performance, complicated and difficult installation procedures, and low material utilization efficiency, and achieve good results. Self-resetting performance, stable self-resetting performance, and effect of improving support self-resetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

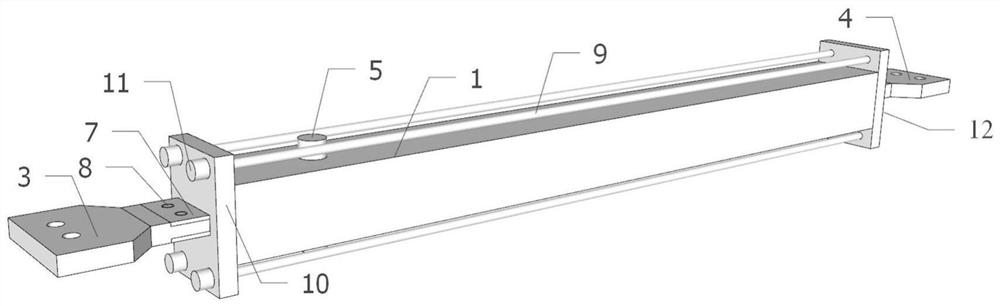

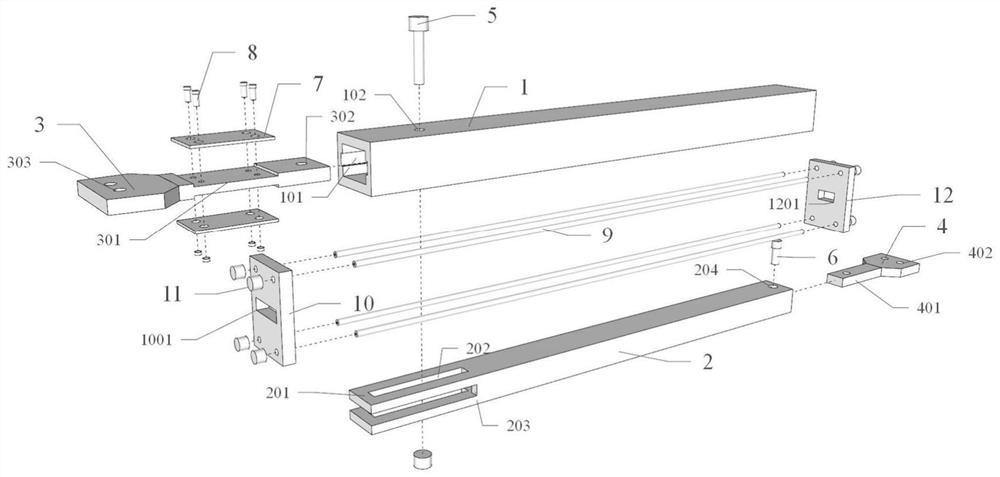

[0032] An assembled self-resetting energy-consuming steel support with SMA cable double sleeves is characterized in that it includes an outer sleeve 1, an inner sleeve 2, an outer sleeve end plate 3, an inner sleeve end plate 4, an end plate 110, and an end plate II12, and several SMA cords9.

[0033] The outer sleeve 1 is a hollow sleeve with openings at both ends.

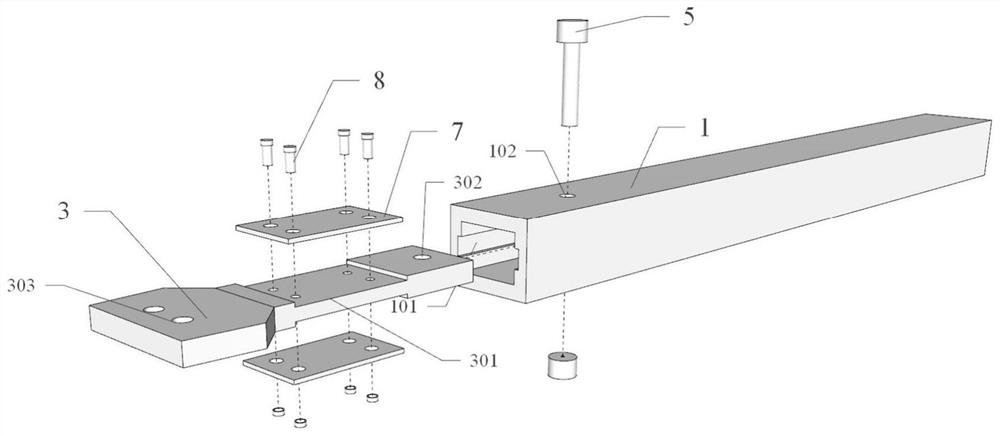

[0034] The inner casing 2 and the outer casing end plate 3 respectively penetrate into the hollow inner cavity of the outer casing 1 from both ends of the outer casing 1 . Wherein, an end plate II12 is provided on the side where the inner sleeve 2 penetrates, and an end plate I10 is provided on the side where the end plate 3 of the outer sleeve penetrates.

[0035] The end plate I10 has a strip-shaped hole I1001 passing through the two plate surfaces. One end of the outer casing end plate 3 passes through the outer casing 1 through the strip hole I1001 and is connected with the outer casing 1 . The other end o...

Embodiment 2

[0040] The main structure of this embodiment is the same as that of Embodiment 1, further, the outer casing 1 and the inner casing 2 are both rectangular casings.

Embodiment 3

[0042] The main structure of this embodiment is the same as in Embodiment 1 or 2. Further, the inner side of the end of the outer casing 1 is partially grooved to form a chute 101 for the outer casing end plate 3 to extend into, and to form a preliminary shape for the outer casing end plate 3. constraint. That is, the two opposite inner side walls of the outer sleeve 1 have slide grooves 101 for guiding and limiting. The two sides of the part where the outer sleeve end plate 3 penetrates into the outer sleeve 1 are respectively located in the two slide grooves 101 , so that the outer sleeve end plate 3 can only slide along the centerline of the outer sleeve 1 in the longitudinal direction. The axial movement of the outer casing end plate 3 is restricted by the high-strength bolt I5, so that the outer casing end plate 3 and the outer casing 1 are integrated, and this process realizes assembly; the hollow hole of the inner casing 2 can be used for the matching installation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com