Quantum dot light conversion film and preparation method thereof

A technology of light conversion film and quantum dots, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of difficulty in forming stable droplets, easy generation of coffee rings, etc., to reduce optical crosstalk and increase stability. , the effect of improving the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

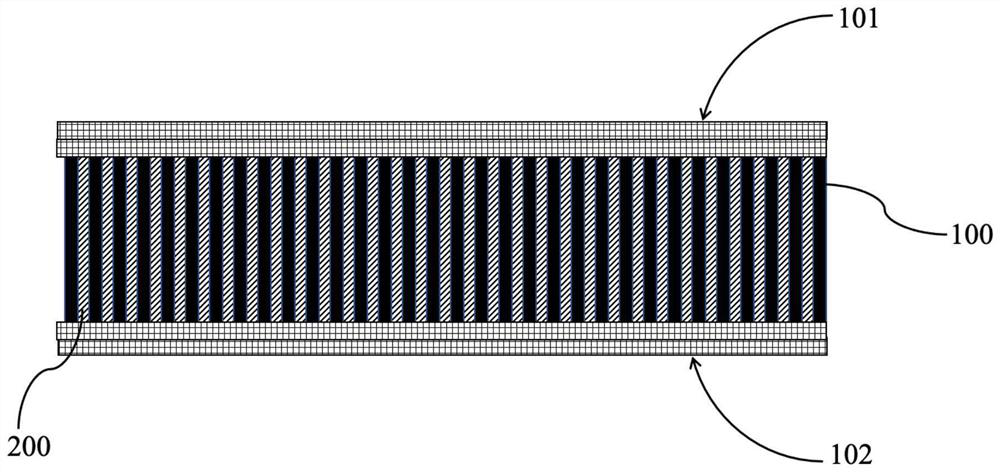

[0035] A quantum dot light conversion film for Micro-LED to improve color gamut and resolution and eliminate mura. The quantum dot light conversion film includes a transparent porous substrate 100, quantum dots 200, a first barrier film 101 and a second barrier film 102, wherein the quantum dots 200 are filled in the transparent porous substrate 100; the first The barrier film 101 and the second barrier film 102 are attached to the upper surface and the lower surface of the transparent porous substrate 100 respectively; the quantum dots 200 are filled in the transparent porous substrate 100 by inkjet printing. The transparent porous substrate 100 is provided with a plurality of through holes passing through its upper surface and lower surface, and the quantum dots are filled in the through holes.

[0036] The transparent porous substrate 100 in the quantum dot light conversion film of this embodiment, and the setting of the first barrier film 101 on the upper surface of the tr...

Embodiment 2

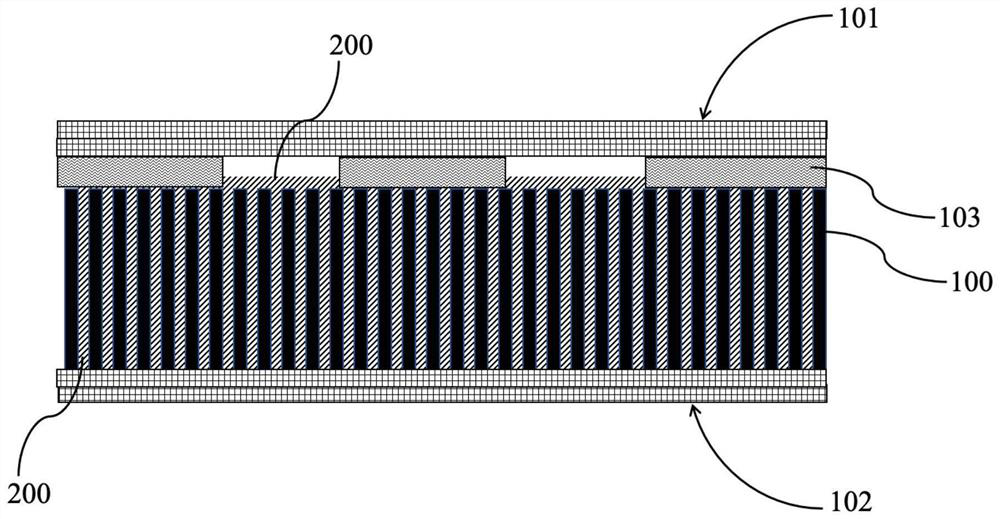

[0041] Please refer to figure 2 , is a structural diagram of the quantum dot light conversion film of the present invention. Only the differences between Embodiment 2 and Embodiment 1 will be described below, and the similarities will not be repeated here.

[0042] A photoresist layer 103 is further disposed between the transparent porous substrate 100 and the first barrier film 101 , and the etching pattern of the photoresist layer 103 corresponds to the pixel pattern. The etch pattern partially fills the quantum dots 200 .

Embodiment 3

[0044] This embodiment provides a method for preparing a quantum dot light conversion film. The method includes: step S1, providing a second barrier film 102, a transparent porous substrate 100 is provided on the second barrier film 102, a photoresist layer 103 is provided on the transparent porous substrate 100, and the photoresist The layer 103 has an etching pattern; step S2, providing quantum dot ink, the quantum dot ink includes an organic solvent and quantum dots with non-polar parts; step S3, printing the quantum dot ink on the upper surface of the transparent porous substrate 100, The quantum dots 200 are filled in the transparent porous substrate 100 in the etched pattern by inkjet printing to form a pixel pattern; step S4, removing the photoresist layer 103; step S5, removing the first The barrier film 101 is attached to the upper surface of the transparent porous substrate 100 filled with quantum dots 200 .

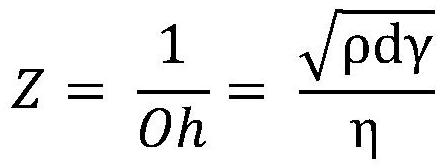

[0045] The pores of the transparent porous substrate 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com